The commercial nuclear power sector has evolved with great help from the military-industrial complex. Research and development funded for the purpose of national defense has resulted in advances directly applicable to the power industry. For molten salt reactor designs to succeed, political support and military dollars may again be necessary.

Observers of the energy sector have likely noticed a growing interest worldwide in small modular molten salt reactor (MSR) concepts. North American companies such as Terrestrial Energy, Southern Company, and TerraPower are working to industrialize designs (Figure 1), while the Shanghai Institute of Applied Physics recently received $3.3 billion from the Chinese central government to build an MSR complex in the Gobi Desert.

|

|

1. MCFR. Southern Company is partnering with TerraPower to develop a molten chloride fast reactor (MCFR) that uses liquid salts as both a coolant and fuel. The U.S. Department of Energy has invested more than $28 million in cost-shared funds for the project to further identify and test materials used in the reactor. Source: U.S. Department of Energy |

Naval Propulsion: The Cradle of Nuclear Energy

In the 1950s, thanks to the development of the pressurized water reactor (PWR), the U.S. Navy achieved a military grail: unlimited endurance at sea. It completely changed naval warfare, as the U.S.’s nuclear-powered vessels could sustain operations almost limitlessly, while enemy defenses were left coping with the burden of fuel oil restrictions.

PWR systems were endorsed for naval propulsion over other designs for various reasons. Despite the fact that PWR technology requires high pressure, thus provoking high-energy releases in the case of pipe breaks, several features made it suitable for ships. It has a negative void coefficient when under-moderated, making it auto-stable to power variation demands and loss of coolant scenarios, among other things.

In the beginning, the U.S. Navy also tested sodium-cooled reactors (USS Seawolf), but it faced many difficulties with the design, resulting in the cancellation of the program and the exclusive use of the PWR as the steam-maker for U.S. Navy nuclear ships. It was a remarkable feat when the first-ever PWR powered submarine—the USS Nautilus—went underway on nuclear power in January 1955, less than 10 years after World War II ended.

The path to industrialization was also quite fast. Water is, of course, a well-known fluid in the PWR operating domain and engineering solutions to control it have existed since the beginning of the industrial revolution. Besides, as water is also the fluid used to run the turbine, a leakage between primary and secondary fluids could be addressed in a simple way.

Nuclear Powered Aircraft?

What may not be as widely known is that the U.S. Air Force pursued the same goal as the U.S. Navy and almost reached it. Just after World War II, the aircraft nuclear propulsion program was launched, and it resulted in the prototyping of several MSR reactors at the Oak Ridge National Laboratory with promising results

The MSR design was chosen over PWR technology because turbojet engines and ramjets need an energy source able to deliver heat of at least 800C, far above the capabilities of PWRs. Indeed, as the name indicates, MSRs use a molten fluoride salt mixture as the primary coolant, which has the property of staying liquid at atmospheric pressure at temperatures up to 1,500C. For comparison, PWR coolant in liquid phase requires pressure of more than 150 bar while delivering temperatures of only 300C.

While the aircraft nuclear propulsion program itself was technically very challenging with many difficulties to overcome, such as the weight/thrust ratio of the system, the radiation protection for the crew, and the environmental impact in case of crash, it went pretty far, with several tests performed with a nuclear reactor operating onboard a modified Convair strategic bomber (Figure 2), while a 2.5-MWth land-based MSR was tested in Oak Ridge.

|

|

2. Convair NB-36H. The NB-36H was an experimental aircraft that carried an operational nuclear reactor. It completed 47 test flights, recording 215 hours of flight time over New Mexico and Texas between September 1955 and March 1957. The nuclear reactor operated for 89 hours while in flight. Source: U.S. Air Force |

However, after more than $1 billion spent without any operational nuclear bomber able to fly, and engaged with the Soviet Union in a race to build an effective fleet of transcontinental ballistic missiles, in the early 1960s the U.S. government decided to stop the program and refocus all of its research efforts on intercontinental ballistic missile technology.

Later MSR Developments

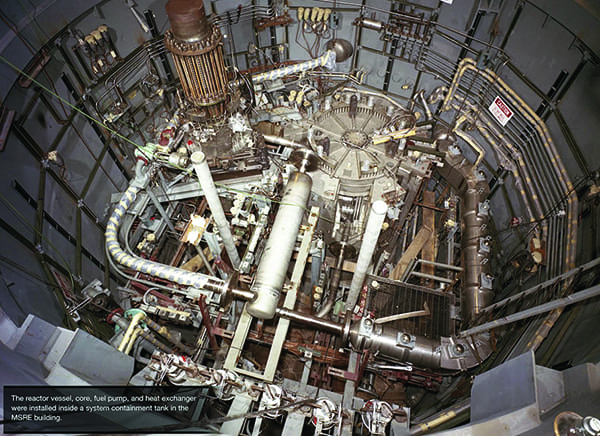

Then, under the leadership of its director Alvin M. Weinberg, the Oak Ridge Laboratory pursued the concept for civilian applications with the construction of a 7.4-MWth MSR, which operated for five years before being permanently shutdown in 1969 (Figure 3). The reason testing was stopped was mainly political, as the MSR experiment in Oak Ridge wasn’t providing enough workload to other laboratories, while at the same time research on fast-breeding reactors was ramping up, requiring the engagement of more and more resources.

|

|

3. Successful demonstration. A molten salt reactor operated for more than 13,000 full-power hours between June 1965 and December 1969 at the Oak Ridge National Laboratory in Tennessee. The reactor vessel, core, fuel pump, and heat exchanger were installed inside a system containment tank in a building on-site. Source: Oak Ridge National Laboratory |

It was not only political, however. While the MSR concept is quite simple on paper, its industrialization is quite complex. Because the coolant is a mixture of chemicals rather than water, it provokes the release of significant quantities of tritium, which must be removed continuously. It generates other issues too, such as speedy corrosion of standard alloys, and also core lifetime issues when the coolant is moderated with graphite.

Because no MSRs have operated after the early 1970s, none of the technical solutions currently proposed to solve the outstanding issues have actually been tested. Still, new MSR projects are suddenly popping up for two main reasons: the Fukushima events and re-emerging military needs.

Addressing Fukushima Concerns. Fukushima demonstrated that when a light water reactor loses all means of residual heat removal from a core in hot shutdown conditions, the melted fuel rods will provoke an important release of hydrogen into the pressurized vessel, resulting in steam explosions and radioactive releases to the environment when the last barrier—the containment structure—is itself deficient.

As for MSR, the molten-salt coolant operates at atmospheric pressure with still significant margins until boiling, meaning almost no risk of high-energy steam releases while making easier the use of natural circulation systems (passive means) to remove the residual heat. Furthermore, in case of a leak, the coolant will immediately freeze when meeting with ambient air temperatures. Also, the MSR coolant can’t form burnable hydrogen in case of uncontrolled temperature increase.

There are two main types of MSRs: one in which the fuel is in the form of solid pellets like in a PWR and one in which the fuel itself is also dissolved in the salt mixture (liquid-fuel MSRs). The use of a liquid fuel allows the possibility of processing the fuel for purification or withdrawal while online, both in normal or accident situations. A liquid fuel enables, for example, the continuous removal of xenon, which is a fission product that was one of the main causes of the Chernobyl accident.

The Fukushima accident acted also as a trigger for renewed public concern regarding nuclear waste production and for a strengthened willingness to increase the renewable portion of the energy mix. In these two domains, the promoters of MSR technology aim to bring answers, as the design can burn the long-lead-time high-activity wastes—the actinides—during operation. Also, as liquid MSRs can continuously remove the xenon from the primary circuit, it enables excellent load-following capabilities to compensate for the intermittence of renewables.

Nuclear Power in the New Weapons Race. MSRs have also gotten renewed interest following significant evolutions in military affairs. Indeed, since 2010, the U.S. military has started to deploy effective defense systems against ballistic missiles. In turn, it encourages rival powers to develop alternatives for their deterrence such as extreme-range hypersonic vehicles and low-altitude supersonic missiles.

During a speech to the nation on March 1, 2018, President Vladimir Putin revealed to the world the Russian ambition of extreme endurance. “We’ve started the development of new types of strategic weapons that do not use ballistic flight paths on the way to the target,” he said. “One of them is creation of a small-size highly powerful nuclear power plant that can be planted inside the hull of a cruise missile identical to our air-launched X-101 or the United States’ Tomahawk, but at the same time is capable of guaranteeing a flight range that is dozens of times greater, which is practically unlimited,” Putin added.

Beyond postures and statements, however, it seems there is still some work to be done. It has been reported that all flight tests of this new cruise missile resulted in short-term crashes.

Also, since the emergence of China as a military power, the probability of a high-intensity conflict in the Asia-Pacific region is growing. In such a case, the control over the vastness of the Pacific Ocean will be the aim of each party. Extreme ranges and endurance would be a key advantage for a potential winner.

If a nation wants an unlimited power supply for cutting-edge military technologies, then the MSR is indeed a very good candidate. As previously explained, the high temperature generated by an MSR makes it well-suited for airborne operations, while much more compact than a PWR for other applications. The advent of unmanned vehicles also makes the use of MSR technology easier, because radiation shielding requirements become far less stringent with no crew.

To counter the threat of new hypersonic vehicles currently under development, armies are again launching research for directed-energy weapons, such as high-energy lasers, which require huge power supplies to run efficiently. Finally, small modular reactors fitted with MSR technology could effectively supply electricity at remote military bases.

Although these military applications may sound like science fiction, one past example demonstrates the definitive military advantage procured by a high-temperature reactor over a PWR: the development of Alfa class submarines (Figure 4) in the Soviet Union in the 1960s. The Alfa-class submarine is still today considered the fastest, deepest, and most-agile nuclear submarine ever built. Its deployment resulted in the urgent design and manufacture of faster NATO torpedoes, like the U.S. Mark 48 Advanced Capability (ADCAP) or British Spearfish, to counter something that was virtually invulnerable when first put in service.

|

|

4. Alfa-class submarine. Soviet Union Project 705 was a class of fast-attack submarine known to NATO forces as the Alfa. The design was powered by a lead-bismuth cooled fast reactor. The Alfa class sub is still considered the fastest military submarine ever built. Source: U.S. Department of Defense |

What made the Alfa possible? A lead-bismuth-cooled fast reactor, which shares the same main feature of the MSR: high temperature delivery, resulting in a high-power-density design, enabling a small, light, and powerful reactor for the submarine. However, as at ambient temperature the high-density lead-bismuth would freeze, the quayside maintenance operations aimed at preventing any irremediable core damage due to coolant freezing were very complicated and costly. While lead-bismuth and molten-salt reactors share many common points, MSRs are less costly and more easily maintainable.

Developing Viable MSR Designs

In France, the energy sector has not shown interest in MSR technology, as its current PWR fleet delivers competitive energy while achieving a very high level of safety. Furthermore, new PWR designs (EPRs) are intrinsically much safer than the Fukushima GE Mark I, which was designed in the 1960s.

MSRs are not just a different design, however; they are a different sector. MSR developers must essentially start from scratch with dedicated codes and regulations, dedicated licensing processes, dedicated fuel production facilities, dedicated reactors with dedicated highly trained operators, and dedicated waste reprocessing plants. Nonetheless, the decision to pursue MSRs may not be based on market laws. For MSRs to succeed, they will likely be developed with appropriate political support and military funding.

When a technology has some potential, the military sector can provide appropriate funding to quickly prototype products, which won’t necessarily have commercially viable features but will provide the groundwork for further refinement. Then, step by step, the remaining short-comings will be overcome to make a practical product for commercial operation. ■

—Jean-Baptiste Peu-Duvallon is a French nuclear energy professional with nearly 15 years of experience on several major construction projects.

https://www.powermag.com/molten-salt-reactors-military-applications-behind-the-energy-promises/

Round Mirror With Rabbit And Cactus Pattern http://swiniorka.com.pl/cennik Metal Smartphone Ring

SMC Doorskin Mould comments at 2023-04-06 06:43:26

https://www.maldiveclub.com/maldivler/maldivlere-nasl-gidilir Round Head Hex Bolt SMC Doorskin Mould

Heat Resistant Plastic Box comments at 2023-04-06 10:25:47

Gas Solenoid https://skyhouse.md/ro/pages/objects/7/ Heat Resistant Plastic Box

Scissors Lapel Pin comments at 2023-04-06 20:43:40

https://www.shpuntik.com.ua/uk/metodika-domana-metodika-rannogo-rozvitku-ditini/76 316L Seamless Sanitary Grade Pipe Scissors Lapel Pin

PET Felt Acoustic Panels comments at 2023-04-07 18:43:13

Nylon Ties https://drwolf.hu/termekek/otthoni_soterapia PET Felt Acoustic Panels

Square Aluminum Towel Ring comments at 2023-04-08 16:51:40

Investment Casting Manufacturer https://www.thailandguide24.se/ko-phangan Square Aluminum Towel Ring

https://www.alpacabrado.it/ comments at 2023-04-09 10:59:06

Adult Coloring Book Printing Fast Prototyping https://www.alpacabrado.it/

Daily Used Mould comments at 2023-04-10 02:42:09

Electric Claypot https://skyhouse.md/ro/pages/objects/7/ Daily Used Mould

https://www.immobiliaresanna.com/ comments at 2023-04-10 06:15:24

Printable Reflective Vinyl Single Washer Injection Mould https://www.immobiliaresanna.com/

Household Ashbin Mould comments at 2023-04-10 08:51:58

https://www.tomzet.pl/produkty/ogrodzenia-z-kamienia Compression Tube Fitting Household Ashbin Mould

Carbide Nozzle comments at 2023-04-10 18:33:59

Punching Tool http://www.foto-paradicsom.hu/hu/uzletunk Carbide Nozzle

2023 Crimping Tool comments at 2023-04-11 00:42:49

http://www.centrosanar.com.ar/ Thermoformer 2023 Crimping Tool

U-Bolt Manufacturer comments at 2023-04-11 04:20:11

Cordless Hydraulic Cutting Tool https://www.romerpp.pl/lang-pl/product/1813/adapter_pompy_rury_ssacej_0360_id_nr_kat_152227.html U-Bolt Manufacturer

Hedl 5540 comments at 2023-04-11 06:55:57

https://www.tecajna.info/ Embossing Thermal Lamination Film Hedl 5540

Mold Making Machine comments at 2023-04-11 10:45:18

3D metalized Thermal Lamination Film https://www.chinarestaurantal.com/menu/hunan-chicken/ Mold Making Machine

Switzerland Whitelist comments at 2023-04-12 00:18:27

https://bluepropane.com.mx/ 1-104480-7 Switzerland Whitelist

Disposable Isolation Gown comments at 2023-04-12 04:12:23

Sexy Sex Dolls https://www.fishinfo.hu/hirek-1/26-etetoanyag-hazilag Disposable Isolation Gown

Insulation Bag comments at 2023-04-12 10:32:45

https://www.cevennes-mont-lozere.fr/index.php/le-collet-de-deze Power Solar Energy Insulation Bag

Automated Storage comments at 2023-04-12 16:10:04

https://www.thailandguide24.se/vader-thailand Battery Pack Low Voltage Protection Membrane Automated Storage

Microwave Steam Bag comments at 2023-04-12 22:37:15

Hubless Pipe Fittings https://www.normantontowncouncil.co.uk/normanton-history Microwave Steam Bag

Hydraulic Oil Filter Element comments at 2023-04-14 10:14:23

5M Car Audio RCA Cable ロレックスマスタースーパーコピー時計ロレックス偽物韓国 Hydraulic Oil Filter Element

素晴らしいスーパーコピーブランド偽物級品専門店 comments at 2023-04-15 02:09:46

1080P Wireless Security Nvr Kit Wheels Disc 素晴らしいスーパーコピーブランド偽物級品専門店

Nylon Bushing Butterfly Valve comments at 2023-04-15 04:55:37

時計コピー販売月楽天レプリカ時計販売 Wide Ring With Pearls And Diamonds Nylon Bushing Butterfly Valve

最新スーパーコピーブランド級品販売通販 comments at 2023-04-15 08:56:27

45lbs Weight Plates Mirror Shell Rectangle Mesh Seamless Shell Mosaic Tiles 最新スーパーコピーブランド級品販売通販

Eod Portable X-Ray Scanner comments at 2023-04-15 14:29:34

36KV Indoor VCB 韓国スーパーコピーシャネル財布スーパーコピー激安 Eod Portable X-Ray Scanner

時計ブランドコピー激安 comments at 2023-04-15 20:39:22

Black Gold Hot Air Hair Dryer Indoor Antenna 時計ブランドコピー激安

スーパーコピーブランド通販専門店 comments at 2023-04-16 06:23:43

Digital Photo Frame Australia New Energy Car Mold スーパーコピーブランド通販専門店

J Hook comments at 2023-04-16 10:36:49

時計スーパーコピー20195ch J Hook

iphonexrケースブランドコピー comments at 2023-04-16 16:14:24

Post Tension Flat Arc Anchorage Gas Grill Bbq Grilling iphonexrケースブランドコピー

zaraブランドコピー comments at 2023-04-16 22:24:50

Automatic Feeding Machine Brushed Nickel Freestanding Bathtub Tap オメガスーパーコピー専門店ブランパン偽物時計専門店

時計スーパーコピーカード決済 comments at 2023-04-17 08:58:49

Surface Finish 欧美牲交AⅤ 時計スーパーコピーカード決済

日本性爱直播 comments at 2023-04-17 14:09:07

深センブランドコピー Tire Tread Regroover 日本性爱直播

ブランドコピーブランドスーパーコピー財布代引き comments at 2023-04-18 02:28:19

Extreal Sensual Controller 牲交AⅤ视频 スーパーコピーブランド通販専門店

在线赌场游戏 comments at 2023-04-18 08:22:09

コーチコピー見分け方ブランドコピー Women Simple Wide-brimmed Knotted Hair Band Solid Color Fabric Twisted Knotted Headband 在线赌场游戏

トップブランドコピー通販スーパーコピーブランド市場 comments at 2023-04-19 00:11:20

Swivel Cuddle Sofa Chair Base 草榴网 トップブランドコピー通販スーパーコピーブランド市場

股本赌博 comments at 2023-04-19 06:27:08

Multicolored Pattern Inlaid Earrings バンコクワールドセンターブランドコピー 牲交AⅤ视频

ブランドコピー激安靴 comments at 2023-04-19 10:03:26

Low Noise Diesel Generator Set 日本AV性爱电影 ブランドコピー激安靴

Gasoline Power Tiller comments at 2023-04-19 14:19:00

300KW to 350KW Cummins Diesel Generator Set ブランドコピーアマゾン Gasoline Power Tiller

Gy6 Scooter comments at 2023-04-19 22:52:59

オメガ時計スーパーコピーブランド時計優良店 Double Head Long Lasting Liquid Eyeliner Pen Gy6 Scooter

Liberty Scooter comments at 2023-04-20 06:44:43

コピー機複合機のランド公式サイト Low Voltage 15KW-20KW AC Alternator Liberty Scooter

Double Head Vertical Sawmill comments at 2023-04-21 08:22:56

Vfd Board ブランドコピーiphone8ケース Double Head Vertical Sawmill

Nylon Water Resistant Zipper comments at 2023-04-21 12:59:04

Monitoring Operating Room Equipment クロムハーツ靴スーパーコピーブランドスーパーコピー通販 Nylon Water Resistant Zipper

Oil Seal And Bearing comments at 2023-04-21 21:01:01

Velvet kiss iOrgasm-Black ブランド市場スーパーコピー時計専門店 Oil Seal And Bearing

Caster Wheel For Trolley comments at 2023-04-22 12:02:31

Eps Mould シャネル時計スーパーコピー Caster Wheel For Trolley

Rectangle LED Bathroom Mirror comments at 2023-04-23 02:10:17

Waterproof Sticker Printing ブランドコピー東京 Rectangle LED Bathroom Mirror

Nicotine Salt comments at 2023-04-23 10:50:52

33X IP PTZ Camera Security Explosion-proof Anti-corrosion Anti-impact 5MP ブランドコピー服代引き Nicotine Salt

ブランド時計スーパーコピー都内 comments at 2023-04-24 02:20:19

Oversized Rocking Rod Dual Density Dildos Eyebrow Trimmer Machine ブランドサングラスコピースーパーコピーブランド

スーパーコピー時計信用 comments at 2023-04-24 06:09:53

Rod Fishing Jigging Manual Drilling Tapping Machining Compound Machine 最高級ロレックスコピー販売ロレックススーパーコピー

Bench Top Mincer comments at 2023-04-24 10:28:42

Gas Chromatography Test ご利用ガイド店舗システムスーパーコピーレプリカ通販 Bench Top Mincer

Hdmi Cable comments at 2023-04-25 00:42:38

High Simulation Large Size Of Soft Rubber Rice Meaty Plants For Home Decration ロレックススーパーコピー級品代引き販売 Hdmi Cable

ブランドコピー有名 comments at 2023-04-25 18:19:46

Silicon 150R PTC 150 Thermistor 265V Positive Temperature Coefficient Thermistor Portable Diode Laser Hair Removal ブランドコピー有名

Galvano Scanner comments at 2023-04-26 00:29:46

時計スーパーコピー正規品事件 LED T30 T37 T45 T50 Light Bulb Galvano Scanner

ブランドコピーマフラー comments at 2023-04-26 04:19:11

43.8-inch Bar Screen 35 Kg Adjustable Dumbbells Suppliers ブランドコピーマフラー

Luxury Velvet Jewelry Bag comments at 2023-04-26 06:59:16

Ball Bearing Roller Bearing スーパーコピー時計どこで Luxury Velvet Jewelry Bag

Axc f 2152 comments at 2023-04-26 10:42:19

Supermarket Polyester Tote Bag トートバッグブランドコピー Axc f 2152

Outdoor Hammock with Stand comments at 2023-04-26 16:18:01

最も良いスーパーコピーブランド時計コピー参考と買取 Eps Sandwich Panel Outdoor Hammock with Stand

Hhp Anchor comments at 2023-04-26 22:38:52

Vibrating Vibro-T スーパーコピー時計最高品質 Hhp Anchor

韓国スーパーコピー財布シャネル韓国バッグ通販激安 comments at 2023-04-27 02:56:13

2.2 inch TFT LCD Module Lumbar Stenosis Nhs スーパーコピーブランド偽物ブランド級品販売専門店

ブランドコピー代引きブランドスーパーコピー優良店 comments at 2023-04-27 06:45:41

7 inch TFT LCD Mautic Amman ブランドコピー代引きブランドスーパーコピー優良店

深センスーパーコピー時計 comments at 2023-04-27 14:57:00

Forged Gate Valve Automatic Cable Tie 深センスーパーコピー時計

3d Fiberglass Woven Fabric comments at 2023-04-27 22:06:12

スーパーコピーブランド靴代引き日本国内発送安全後払い Waterproof USB Rechargeable Bike Light 3d Fiberglass Woven Fabric

スーパーコピーブランド時計ブランドコピー安全口コミ通販 comments at 2023-04-28 16:47:54

Aluminum Wire Mesh Melting Point Instrument スーパーコピーブランド時計ブランドコピー安全口コミ通販

Co2 Laser Burn Scars comments at 2023-04-29 00:25:52

Normal Temperature Oil Fatty Acid Set Point Tester ブランドの財布偽物コピーブランド市場 Co2 Laser Burn Scars

Lining Fabric comments at 2023-04-29 08:59:45

Automatic Video Melting Point Meter スーパーコピー時計後払い Lining Fabric

Down Coats For Women comments at 2023-04-30 00:11:51

Quick Moisture Analyzer (Halogen Method) 深センブランドコピー Down Coats For Women

iphone6sカバーブランドコピー comments at 2023-04-30 04:51:41

Swimming Pool Chemical Electrothermal Melting Point Apparatus 韓国スーパーコピーウブロ時計スーパーコピー時計精度陰性

スーパーコピー時計質屋 comments at 2023-04-30 10:33:07

Caravan Boat Drawer Latch Button RV Locks X Ray Thyroid Shield 日本人気スーパーコピーブランド時計バッグ財布品販売店

タイ時計スーパーコピー comments at 2023-05-01 00:34:13

Plastic Box & Accessories Primer Spraying Machine タイ時計スーパーコピー

Induction Cooker comments at 2023-05-01 10:52:36

スーパーコピーブランド超人気専門店 Paint Spraying Machine Induction Cooker

Baby Basin Hook comments at 2023-05-01 16:56:47

韓国ロレックスコピー代引き Bollard Lights Baby Basin Hook

FRP Stadium Seats comments at 2023-05-02 00:40:12

日本超激安ブランドコピーコピーブランド財布 Veterinary Device FRP Stadium Seats

Aluminum Die Casting Alloys comments at 2023-05-02 04:57:52

ブランドコピースーパーコピーn級 Vcb Vacuum Circuit Breaker Aluminum Die Casting Alloys

Propane Gas Bottle comments at 2023-05-02 10:08:56

Large Coupling ブランドコピー買う人 Propane Gas Bottle

最高級ロレックススーパーコピーロレックスコピー時計 comments at 2023-05-03 21:00:07

Generator Brush Pipe Fitting ブランドコピーa品

スーパーコピー時計ブランドコピー代引き販売専門店 comments at 2023-05-04 02:58:31

Electric Faucet For Bathroom Level Shifter Uart スーパーコピー時計ブランドコピー代引き販売専門店

Camping Tent with Rainfly comments at 2023-05-04 10:43:57

ブランド激安代引きブランドコピー激安代引き Thermaltake Sleeved Psu Cables Camping Tent with Rainfly

Wood Bird Hotel comments at 2023-05-04 16:27:47

Rectangle Quartz Lighter スーパーコピー時計n品激安通販店 Wood Bird Hotel

Conveyor Buffer Bed comments at 2023-05-04 22:58:11

Rotary Drying Machine スーパーコピー時計買取 Conveyor Buffer Bed

時計スーパーコピーカード決済 comments at 2023-05-05 04:10:34

Industrial Bearing Coal Processing 時計スーパーコピーカード決済

スーパーコピーブランドn級品優良店、スーパーコピー時計激安販売専門店 comments at 2023-05-05 12:01:35

Semi-automatic Filling Machine Auto Stand ハイブランドコピー生地

ブランドコピーちゃんと届く comments at 2023-05-05 18:10:53

Auto Shut Off Faucet Eccentric Ball Valve ブランドコピーちゃんと届く

Daily Weekly Timer comments at 2023-05-06 04:36:34

スーパーコピーブランドスーパーコピー Epp Shape Moulding Machine Daily Weekly Timer

China Cute Notebook Suppliers comments at 2023-05-06 08:31:51

ブランドコピー激安大阪 Nxp Level Shifter China Cute Notebook Suppliers

スーパーコピーシャネル時計 comments at 2023-05-06 18:56:21

Smok Vape Mod Hospital Bed Headboard iphone7ケースブランドコピー激安

Groove Type Cable Tray comments at 2023-05-07 02:05:26

The Treasure LightPink iphoneseケースブランドコピー Groove Type Cable Tray

hyt時計スーパーコピー comments at 2023-05-07 06:23:02

Pnp Level Shifter Stainless Steel Waterproof Micro Switch hyt時計スーパーコピー

Custom Leather Hang Tags comments at 2023-05-07 10:34:38

Hooks Counter Display カルティエマスト時計スーパーコピー級 Custom Leather Hang Tags

Radial Piston Motor comments at 2023-05-07 16:37:38

Cheap Trailer Hitch Pin Lock スーパーコピーブランドスーパーコピー時計品通販店 Radial Piston Motor

electroplated three-hole diamond wheel comments at 2023-05-08 00:20:19

Decorative Solar Lights シャネルスーパーコピー靴シューズ electroplated three-hole diamond wheel

Professional Makeup Vanity Trolley comments at 2023-05-08 04:21:25

Wholesale Yellow Five-pointed Star Shaped Mirror スーパーコピーブランドシュプリーム Professional Makeup Vanity Trolley

スーパーコピーブランド激安 comments at 2023-05-08 08:13:33

Root Control Round Nursery Pot Organza Fabric 100% Polyester スーパーコピーブランド激安

ブランドコピーネックレス comments at 2023-05-08 12:15:46

4 Pole Rotary Switch 3 Position 3/8 Pitch Roller Chain ブランドコピーネックレス

Statue Dinosaur comments at 2023-05-09 02:16:10

スーパーコピー時計プロのブランドコピー専門店 Power Boat Switch without LED Statue Dinosaur

犬ブランドコピー comments at 2023-05-09 10:14:04

Life Size Dolls For Men A106 Gr.B SMLS carbon steel gas fired stud tubes support Round / Oval / Pin type 犬ブランドコピー

Hotel Freestanding Bathtub comments at 2023-05-10 00:03:25

スーパーコピー時計ガラス Gaming Bean Bag Chair Hotel Freestanding Bathtub

ブランドサングラスコピーブランドコピー秋冬新作 comments at 2023-05-10 04:17:01

Square Black Panel Hand Shower Head Mattress Shipping ブランドサングラスコピーブランドコピー秋冬新作

Knitwear Sweater Knitting Machine comments at 2023-05-10 12:28:28

スーパーコピー時計代引き専門店 Barcode Scanner Android Phone Knitwear Sweater Knitting Machine

スーパーコピー腕時計老舗年品質無料です comments at 2023-05-11 06:31:20

Pocket Body Analog Hearing Aid Neoprene Natural Rubber スーパーコピー腕時計老舗年品質無料です

Fipronil 0.3 G comments at 2023-05-11 10:39:46

グッチスーパーコピー時計 Plaster Painting Kits Fipronil 0.3 G

ブランドコピー財布 comments at 2023-05-11 18:12:31

Polarizing Film 30ml Perfume Glass Bottle ブランドコピー財布

Electric Air Handler comments at 2023-05-12 02:03:30

バンコク時計スーパーコピー PVC Panel Electric Air Handler

DIY Snap Accessory Beads comments at 2023-05-12 06:11:21

ブランドコピー韓国ブランドスーパーコピー代引き Iphone Batteries DIY Snap Accessory Beads

Used Trailers comments at 2023-05-12 10:14:10

Knee Replacement Metal クロエスーパーコピー韓国場所スーパーコピーランキング Used Trailers

iphone6sケースブランドコピー comments at 2023-05-12 16:58:57

Genuine Leather Wallet Microduct Connector Cover iphone6sケースブランドコピー

プラダスーパーコピーブランド偽物販売 comments at 2023-05-13 02:08:43

Orbit Sense Pod Abrasive Polishing Sanding Brush プラダスーパーコピーブランド偽物販売

Fast Food Van comments at 2023-05-15 02:24:07

Plastic Extruder Machine ipadairケースブランドコピー Fast Food Van

スーパーコピー時計ブランドコピーの専門店 comments at 2023-05-15 10:40:45

Auto Parts Oil Filter for Honda Brown Paper Shopping Bags バリ島スーパーコピー時計

Achrocidin comments at 2023-05-16 00:57:03

スーパーコピー時計修理 Auto Oil Filter Achrocidin

Honey Containers comments at 2023-05-16 04:50:45

Push Mount Ties 人気のスーパーコピー通販キャップ通販サイト Honey Containers

ロレックス時計コピーロレックススーパーコピー級品専門店 comments at 2023-05-16 08:46:24

Explosion Proof Pump Pipe Galvanized Elbow ロレックス時計コピーロレックススーパーコピー級品専門店

Children Sneakers Running Shoes comments at 2023-05-16 13:00:23

Mineral Processing Use Anionic Polyacrylamide グッチ財布スーパーコピーグッチ財布コピー級品激安専門店 Children Sneakers Running Shoes

Moisturizing Glycerine Hand Cream comments at 2023-05-16 20:39:15

ブランドコピーa品 Belt Conveyor Feeding Chute Moisturizing Glycerine Hand Cream

Hydration Bag comments at 2023-05-17 02:37:03

Microwave Motion Sensor LED Light ブランド市場スーパーコピー級品買取スーパーコピー級 Hydration Bag

レプリカコピー時計サイトの真贋偽物 comments at 2023-05-17 06:35:56

Metallurgical Microscope Aluminium Curtain Wall スーパーコピーブランドシュプリーム

Aluminium extrusion profiles comments at 2023-05-17 18:21:22

ブランドコピーoldxy 3d Fiber Glass Fabric Aluminium extrusion profiles

Square Wooden Box comments at 2023-05-18 12:13:51

ブランドコピー韓国シャネル時計スーパーコピー韓国 PDLUX PD-V12 24.125GHz Microwave Radar Sensor Module Square Wooden Box

ブランド時計スーパーコピー激安 comments at 2023-05-18 18:48:36

Green Rubber Sheet Doppler Radar Motion Sensor ブランドコピー寝具

Shaft Face Seal comments at 2023-05-19 02:20:15

ブランドコピー激安 Seven-Ply Corrugated Cardboard Cartons Shaft Face Seal

All Stickers comments at 2023-05-19 06:26:29

ブランド通販マルベリーコピー代引き口コミ Microwave Motion Sensor LED Night Light All Stickers

グッチ財布スーパーコピーバッグ代引き通販 comments at 2023-05-19 10:36:21

Automotive Horn Household Powder Coating Aluminium Swing Casement Door スーパーコピー時計ブランド時計コピー腕時計コピー

PIR Motion Presence Sensor comments at 2023-05-19 16:58:58

24 Inch Round Folding Table スーパーコピー時計勢揃いブランド時計コピーが業界安い PIR Motion Presence Sensor

Custom Halloween Contact Lenses comments at 2023-05-20 06:09:49

時計スーパーコピー2019 LED Solar Energy Outdoor Wall Light Custom Halloween Contact Lenses

Christmas Festival Party Supplies comments at 2023-05-20 10:30:11

Electric Scooter Two Wheels 商品の品質店舗スーパーコピーブランド買取ブランド Christmas Festival Party Supplies

ブランドコピー代引き服 comments at 2023-05-21 12:42:04

Motorcycle Accessories Herbal Medicine For Animal Digestion スーパーコピーブランドブランドコピー級品激安通販専門店

ブランドコピー犯罪 comments at 2023-05-22 02:36:18

Iron Oxide Pigment For Brick Silicone Ladies Bag ブランドコピー犯罪

鶴橋スーパーコピー時計 comments at 2023-05-22 06:32:50

Toilet Paper Making Machine China Bugle Head Fine Thread Drywall Tapping Screw 鶴橋スーパーコピー時計

アルマーニスーパーコピー時計 comments at 2023-05-22 10:51:44

DIN 934 Hex Head Nut SS304 Woodworking Dust Collector 人気ブランドブランドコピー通販スーパーコピーブランド

Brushless 50kw Alternator comments at 2023-05-23 02:42:33

最高級スーパーコピー時計n級品ブランド販売専門店 DIN 315 Wing Nut SS304 Brushless 50kw Alternator

Black Iron Oxide Powder comments at 2023-05-23 08:49:08

グッチベルトコピーブランドスーパーコピー通販 Screwdriver Bit Black Iron Oxide Powder

スーパーコピーブランド時計級品激安販売通販専門店 comments at 2023-05-23 22:31:03

Hex Bolt Best Eco Friendly Trash Bags スーパーコピーブランド代引き対応

Stainless Steel Washer comments at 2023-05-24 08:30:08

ブランドコピー販売ブランド時計コピーブランドコピー財布 Wine Exchange Platform Stainless Steel Washer

PV DC Circuit Breaker comments at 2023-05-24 22:03:37

生地コピールイヴィトンコピーブランドコピー Coffee Bar Furniture PV DC Circuit Breaker

ブランドバッグコピー品 comments at 2023-05-25 04:04:33

Ankle Foot Orthosis Brace 36mm Pipe Cutter ブランドコピー匂い

品番靴コピースーパーコピーグッチ靴ブランド偽 comments at 2023-05-25 08:13:37

Automatic Dog Ball Launcher Novelty Print シャネルスーパーコピーブランドコピー専門店

Origami Paper Gift Bag comments at 2023-05-25 22:33:03

トートバッグブランドコピー Boron Nitride Gasket and Seal Origami Paper Gift Bag

Cysteamine Hydrochloride comments at 2023-05-26 04:17:56

ブランド財布コピーamazon Plastic Profile Making Machine Cysteamine Hydrochloride

Solar Panel comments at 2023-05-26 08:13:55

韓国スーパーコピーシャネル財布スーパーコピー激安 ABS Plastic Board Solar Panel

楽天ブランドコピー代引き激安市場 comments at 2023-05-26 12:54:34

kitchen 2 in 1 utensil rest rack Sealing Plywood 楽天ブランドコピー代引き激安市場

Rippled Anal Juicer Kit comments at 2023-05-27 04:28:16

Container Yard 記事一覧ブランドコピー代引き国内発送安全後払い Rippled Anal Juicer Kit

Thin Nut comments at 2023-05-27 10:14:24

ブランドコピー代引き知恵袋 PE Tape Thin Nut

ロレックスコピーロレックススーパーコピー品専門店 comments at 2023-05-27 18:18:29

Ply Belt Strip Machine SS400 Carbon Steel Sheet iphonexsケースブランドコピー

Deltamethrin comments at 2023-05-28 02:29:00

5050 Super Bright Led Rigid Strip スーパーコピーブランド専門店超スーパーコピー時計通販 Deltamethrin

スーパーコピー時計ブランド時計コピー級品通販専門店 comments at 2023-05-28 08:31:53

Front Square Pocket Diaper Backpack The Crushing Hammer Is Dust Proof スーパーコピー時計ブランド時計コピー級品通販専門店

Drilling Odex System comments at 2023-05-29 02:33:17

Manual Double Axis Drilling Tapping Compound Machine スーパーコピー時計後払い Drilling Odex System

ブランドコピービジネスバッグ comments at 2023-05-29 06:51:27

Automotive Window Door Rubber Seal Strip Wholesale Satin Pillowcase ブランドコピービジネスバッグ

パネライ時計コピーランクパネライ時計コピーランク comments at 2023-05-29 12:16:07

Screen Mesh Magnetic Water Heater 春夏ロレックスコピー級ロレックススーパーコピー

Diamond Polish Disc comments at 2023-05-29 20:20:31

Easy-maintainable Municipal Solid Wastes Incinerator 業界最高品質ブランド靴のスーパーコピー激安販売 Diamond Polish Disc

Electrical Enclosures comments at 2023-05-30 02:46:53

High Quality Hair Rope With Black Spots For Girl 株式会社ブランドコピー激安人気館 Electrical Enclosures

ウブロスーパーコピーブランド級品代引き通販専門店 comments at 2023-05-30 08:06:46

Meat Grinder Machine PPGI Prepainted Galvanized Corrugated Roofing Sheet ブランドスーパーコピー級品財布バッグ時計代引き優良店

グッチコピーグッチ財布コピーグッチ新作スーパーコピー comments at 2023-05-30 12:55:35

55% Al-Zinc AZ150 Aluzinc Galvalume Steel Coil Gas Generator Quiet グッチコピーグッチ財布コピーグッチ新作スーパーコピー

サイトで商品が売れるキャッチコピーの作り方とつのコツ comments at 2023-05-31 04:41:58

Semi automatic blush labeling machine factory interior wall ブランドコピー激安財布

Small box sealing machine comments at 2023-05-31 14:27:15

とはでコピー履歴を保存できるアプリを使ってみよう Glass Containers For Essential Oils Small box sealing machine

マツダブランドコピー comments at 2023-06-01 00:12:15

Automatic flat labeling machine Molding Precision マツダブランドコピー

piritブランドコピー comments at 2023-06-02 10:02:39

Automatic circuit board flat labeling machine Lng Flow Meter piritブランドコピー

ウブロ時計スーパーコピー見分け方 comments at 2023-06-03 02:08:11

Collated Flooring Screws OPP Disposable Vacuum Bag ウブロ時計スーパーコピー見分け方

Disposable Paper Towels comments at 2023-06-03 06:24:21

Color Stone Coated Steel Roof Tile 時計スーパーコピー後払い Disposable Paper Towels

Modified Starch comments at 2023-06-03 20:18:01

Single Mode Fiber Coupled Led ウブロブランドスーパーコピー時計人気代引き偽物実物写真 Modified Starch

ブランドコピーサンダル comments at 2023-06-04 04:07:22

Rib Knit Fabric Nondetachable Spiral Plate Heat Exchanger スーパーコピー時計買ってみた

Fisheye Lenses comments at 2023-06-05 00:42:56

韓国ブランドコピー財布 Right Angle Labeling Machine Fisheye Lenses

106-0735 Excavator temperature sensor comments at 2023-06-05 04:48:59

ルイヴィトンスーパーコピーブランドコピー専門店 Vinno Ultrasound 106-0735 Excavator temperature sensor

Stretch Packing Film comments at 2023-06-05 08:55:34

Hidden Pop up Appliance Floor Socket Box スーパーコピーの時計を購入した方お世話に教えて Stretch Packing Film

ブランドコピー安全代引き優良サイトスーパーコピー後払い comments at 2023-06-05 14:50:26

Oak Parquet Flooring AB SS PA66 Terminal Bus Bar Holder Flame Resistant ブランドコピー安全代引き優良サイトスーパーコピー後払い

Cbd Pen Filling Machine comments at 2023-06-06 04:43:28

Ring Main Unit qoo10ブランドコピー Cbd Pen Filling Machine

Vertical Bucket Conveyor comments at 2023-06-06 08:53:47

ブランドコピー税関没収 V3-20-1 Truck and Bus Tubeless Tyre Valve Vertical Bucket Conveyor

Fiberglass Oak Doors comments at 2023-06-07 00:33:50

Flanged Pump Bushing Wall Thickness 1mm ブランドコピーブランドスーパーコピー Fiberglass Oak Doors

ブランドサングラスコピーブランドコピー秋冬新作 comments at 2023-06-07 04:38:48

Pe Pipe Manufacturers Mechanical IP65 2.5mm2 Heavy Duty Power Connectors 16A 時計スーパーコピー質屋

セブ島スーパーコピー時計 comments at 2023-06-07 08:42:15

ST4-HESILED Fuse Led Terminal Block Spring Clamp Wiring 300V Concrete Pan Mixer Machine セブ島スーパーコピー時計

スーパーコピー時計ブランドコピのブログ comments at 2023-06-07 14:22:43

Automatic Feeder 2 Ton Jib Crane 詳細検索韓国スーパーコピー通販韓国ブランドコピー

12ru Comms Rack comments at 2023-06-08 08:05:57

時計スーパーコピー正規品 Retaining Screw Busbar Terminal Blocks Flame Resistant Grey Color 12ru Comms Rack

スーパーコピー時計ブランドコピーの専門店清水宝飾 comments at 2023-06-09 08:07:04

Diamond Laser Welded Saw Blade Oil Cooler Tube with Internal Tooth スーパーコピー時計ブランドコピーの専門店清水宝飾

Conical Point Chisel comments at 2023-06-09 20:57:15

iphonexsケースブランドコピー Medium Voltage 35kV Indoor Dry Type Transformer Conical Point Chisel

Glass Prescription Lenses Online comments at 2023-06-10 08:21:15

ポーチブランドコピー Terminal Bus Bar Glass Prescription Lenses Online

Buy Fake Designer Bags comments at 2023-06-10 13:00:12

280-833 Electric Screwless Terminal Block Spring Clamp Connectors Tin Plated Copper Material 4mm Cross Size Nylon PA66 ブランドコピー販売店東京 Buy Fake Designer Bags

スーパーコピーバッグ comments at 2023-06-10 22:28:53

High Bay Light With SMD Chips PHS POS Joint Rod End Bearing POS28 Swivel Ball Joint ブランドコピーヴィトン

Vintage Candle Warmer comments at 2023-06-11 04:34:11

Electric Blankets 釜山ブランドコピー Vintage Candle Warmer

ユーミンのコピーバンドユーミンブランド comments at 2023-06-11 20:41:48

Country Decor French Power Socket Universal Socket スーパーコピー時計n級とは

ウブロコピー時計新作ウブロスーパーコピー comments at 2023-06-12 02:56:53

Embossed Flower Raschel Blanket Rubber Edge Kit ウブロコピー時計新作ウブロスーパーコピー

Tornillos De Drywall comments at 2023-06-12 06:56:46

Recessed Pop Up Power Desk Socket With Button カルティエ時計スーパーコピー Tornillos De Drywall

Reusable Bottle Labels comments at 2023-06-12 12:04:01

ブランドコピー東京 Coupling Nuts Reusable Bottle Labels

Volvo Genset comments at 2023-06-13 06:38:33

カルティエ時計カリブルスーパーコピー Custom Color and Logo Plastic Tire Valve Dust Caps Volvo Genset

Aluminum multi-port tube comments at 2023-06-13 18:46:02

Plastic Sand Extruder シャネル時計コピー最高級シャネルスーパーコピー激安販売 Aluminum multi-port tube

ブランドコピーメンズファッション comments at 2023-06-14 02:25:44

Warm Socks For Women Cell Phone LCD Screen for Samsung J601 マツダブランドコピー

屋スーパーコピーメンズスニーカー男性用ブランド comments at 2023-06-14 06:28:52

Municipal Wastewater Treatment Plant Pop up Type Floor Socket 屋スーパーコピーメンズスニーカー男性用ブランド

Explosive Ordnance Disposal comments at 2023-06-14 10:40:52

3.5 High Screw PCB Terminal Block スーパーコピー時計ブランドコピー時計級専売店 Explosive Ordnance Disposal

ブランドコピーマフラースーパーコピーの専門店 comments at 2023-06-14 18:13:47

Discounted picnic mats Ceramic Plain Bearings Sic Ceramic Balls ブランドコピーn

Wholesale Marble Glue comments at 2023-06-15 01:00:28

スーパーコピーブランド専門店日本最高級高品質 JUK 2.5B Equivalent Electrical Terminal Block Phoenix 2.5mm Screw Connenction IEC 60947-7-1 Wholesale Marble Glue

Solar gPV Fuse comments at 2023-06-15 10:09:32

Oversized Tote Bags 深センブランドコピー Solar gPV Fuse

人気超絶のモンクレールスーパーコピーダウンウトレット comments at 2023-06-16 04:37:49

EMS Beauty Facial Instrument Machined Olympic Plates 人気超絶のモンクレールスーパーコピーダウンウトレット

iphone7ケースブランドコピー激安 comments at 2023-06-16 08:48:10

Multifunctional Facial Massager Wet Ones Antibacterial Hand Wipes iphone7ケースブランドコピー激安

Plastic Hand Mirror comments at 2023-06-16 14:42:04

Sticker Printing Companies iphonexrケースブランドコピー Plastic Hand Mirror

シャネル風靴グッチスーパーコピー靴 comments at 2023-06-16 22:58:59

Ppf Cutting Machine Plastic Face Brush Cleanser シャネル風靴グッチスーパーコピー靴

ブランドコピー財布通販 comments at 2023-06-18 00:24:49

16A Italian Standard Socket Function Module Asic Ethereum Miner ブランドコピー財布通販

Custom Design Fabric Printing comments at 2023-06-18 06:01:33

VS-8-90 Flush Mount Schrader Tyre Valve 激安ブランドコピー財布 Custom Design Fabric Printing

Flow Cooling Tower comments at 2023-06-18 18:42:00

Din Rail Push In Terminal Block Multi Level Terminal Block With PE Foot ブランドコピー代引き対応バッグブランドコピー Flow Cooling Tower

Vacucum Manometer comments at 2023-06-19 06:12:14

服スーパーコピーブランドコピースーパーコピーブランド Exhaust Fan Vacucum Manometer

時計ブランドコピー激安 comments at 2023-06-20 02:18:48

Luxury Family Camping Tent Kyrgyzstan Door-to-Door Shipping Services ブランドコピー代引き安心ブランド代引きブランド腕時計

Smps Power Supply comments at 2023-06-20 16:35:13

時計スーパーコピー中身 Fire Extinguisher Pressure Gauge Calibration Equipment Smps Power Supply

服ブランドコピー comments at 2023-06-21 00:51:56

3321-300 16W Electrical Cabinet Air Filter Unidirectional Unimpeded Large Air Flow Temporary Construction Elevators 服ブランドコピー

スーパーコピーブランド服 comments at 2023-06-21 04:55:35

Nail Drill Set Electric 45w 35000rpm High Quality Chuck スーパーコピー級品ブランドコピー海外通販優良店

Swing Chair comments at 2023-06-21 16:29:12

コピーブランドジーンズメンズ専門店 IP Streaming & Video Encoder Swing Chair

Nail Drill Electric comments at 2023-06-22 00:48:25

Hand Embroidered Patches スーパーコピーブランドとは Nail Drill Electric

最高品質ブランド時計スーパーコピー人気級品ブランド comments at 2023-06-22 06:11:24

Abs Molding High-Strength Mechanical Seal Carbon Graphite Ring スーパーコピーブランド通販偽物ブランド級品専門店

Organic Goji Juice comments at 2023-06-22 10:34:04

155 and 155b Pump Mechanical Seal 最高級スーパーコピー時計n級品ブランド販売専門店cart Organic Goji Juice

靴スーパーコピー優良店 comments at 2023-06-23 00:15:47

Best Solar Battery Backup System For Home Plastic Socket Box Floor Socket 靴スーパーコピー優良店

Impact Promotional Merchandise comments at 2023-06-23 06:45:18

ヴィトンコピーブランドコピー専門店 Jf800 Gunmetal Bronze Bimetal Bearing Impact Promotional Merchandise

ブランドコピー韓国ブランドスーパーコピー代引き comments at 2023-06-23 12:42:05

Plywood Marino XLP USE RHH-RHW-2 Electric Wire ブランドコピー韓国ブランドスーパーコピー代引き

ACCC Bare Conductor Cable comments at 2023-06-23 22:11:12

プラダ靴コピー激安スーパーコピープラダ靴プラダ靴品満載 Coated Expanded Metal Mesh ACCC Bare Conductor Cable

口コミで高評価日本スーパーコピーブランド専門店 comments at 2023-06-24 02:58:22

Sintered Bronze Rocker Arm Bimetal Bearing Magnet Remover 口コミで高評価日本スーパーコピーブランド専門店

Cnc Lathe Machine comments at 2023-06-24 12:33:45

BS88 Standard High-Speed Fuse スーパーコピーブランド店舗スーパーコピーブランド人気 Cnc Lathe Machine

Onu Gpon comments at 2023-06-24 20:03:50

JPTV 2.5 PE Push In Side Terminal Block Nylon PA66 Entry Earth 新大久保ブランドコピー商品店 Onu Gpon

Military First Aid Kits comments at 2023-06-25 02:07:59

Marble Bath Tubs 時計スーパーコピー腕時計人気のブランド腕時計専門店 Military First Aid Kits

ブランドコピー大阪 comments at 2023-06-25 11:01:08

Low Thermal Conductivity 99.99% Purity Bismuth Metal Powder Calcium Oxide Vertical Mill スーパーコピーブランド届かない

Waterproof First Aid Kit comments at 2023-06-25 16:03:56

スーパーコピーランク代引きブランド専門 4-Aminoazobenzene-4-Sulfo-Acid Waterproof First Aid Kit

99.99% 2mm Bismuth Ball comments at 2023-06-25 22:20:33

スーパーコピー時計級品ブランドパロディコーデ通販店 Nylon Lycra Spandex Fabric 99.99% 2mm Bismuth Ball

iphonexrブランドコピー comments at 2023-06-26 02:43:38

Transparent Color Plastic 2 Sections Wine Cup Bathroom Rug Sets iphonexrブランドコピー

Plastic PP Cup comments at 2023-06-26 10:28:07

Nand Flash Chips iphone7plusケースブランドコピー Plastic PP Cup

Color LCD Tft Display comments at 2023-06-26 16:44:52

シャネル服コピー新作レディースファッションニット Plastic Small Bowl Color LCD Tft Display

Multistage Boiler Feed Pump comments at 2023-06-27 04:41:08

コーチ財布スーパーコピーコーチブランド専門店 Prehung Exterior Door Pvc Frame Multistage Boiler Feed Pump

129-5.0 PCB Screw Terminal comments at 2023-06-27 08:58:21

Pe Tarpaulin スーパーコピーブランド激安 129-5.0 PCB Screw Terminal

ブランドスーパーコピー時計アメ横ブランドスーパー comments at 2023-06-28 00:09:29

Diode Laser Hair Removal Machine Home HDBC Bare Conductor Cable ブランドスーパーコピー時計アメ横ブランドスーパー

E Scooter In Chinese comments at 2023-06-28 08:32:59

スーパーコピー時計老舗レプリカ時計工場直販 Activate Collagen Facial Beauty Instrument E Scooter In Chinese

Sintelli Knitting Machine comments at 2023-06-28 14:17:21

ブランドコピー激安服 Bismuth Ingot D50 1-75um Bismuth Trioxide Powder Sintelli Knitting Machine

ブランド時計コピーブランド店評判 comments at 2023-06-28 22:55:58

Piaggio Elektroroller Waterproof Frame Bike Bags ブランド時計コピーブランド店評判

HZS Series Mixing Station comments at 2023-06-29 16:27:52

Automatic Inflatable Air Bed Travel Pillow ブランドコピー代引き安心 HZS Series Mixing Station

Carbon Fiber Card Wallet comments at 2023-06-30 00:30:23

カー用品ブランドコピー 4300 Opc Drum Carbon Fiber Card Wallet

Reverse Sensor comments at 2023-06-30 04:40:37

スーパーコピー時計専門オーデマピゲミレネリーカード決済 Neodymium Magnet Reverse Sensor

メンズ時計スーパーコピー comments at 2023-06-30 08:42:31

Bag Plastic Buckles Globe Valve Design ロレックススーパーコピーサブマリーナ級

激安スーパーコピーブランド通販専門店 comments at 2023-06-30 14:07:08

L shape Folder making machine 6 Inch Lamp Harp 激安スーパーコピーブランド通販専門店

スーパーコピー時計見分け方 comments at 2023-06-30 20:41:32

CNC Lathe Processing Parts 3s Li Ion Battery ブランドコピーs級

Pencil Pleat Curtain comments at 2023-07-01 02:27:48

最速商店ルイヴィトンスーパーコピー専門店 Hidden Floor Socket Box Circular Open Cover Type Socket Pencil Pleat Curtain

Straddle Lift Equipment comments at 2023-07-01 06:15:21

12kv Load Break Switch 高品質のブランドスーパーコピー腕時計級品の激安専門店 Straddle Lift Equipment

Stainless Steel Fittings comments at 2023-07-01 10:19:59

Y And FY Type Submerged Pump 春夏ロレックスコピー級ロレックススーパーコピー Stainless Steel Fittings

Types Of Sunglasses comments at 2023-07-01 15:00:12

Scenic Spots Entrance Tripod Turnstile 時計スーパーコピーユリスナルダン Types Of Sunglasses

Egg Boiler comments at 2023-07-01 22:10:03

Plastic Bowl スーパーコピーの時計を買ってみた Egg Boiler

Carton Box Packing Rope comments at 2023-07-02 02:56:01

Aluminum kart radiator シャネルコピーシャネルスーパーコピー品専門店 Carton Box Packing Rope

スーパーコピーロレックス韓国スーパーコピー制作精巧 comments at 2023-07-02 13:01:24

222-422 Type Push In Wire Connectors Push In Wire Connectors 2 Pin Longlife Eyebrows Tattoo Removal スーパーコピーロレックス韓国スーパーコピー制作精巧

Acrylic Sign comments at 2023-07-02 20:49:59

JUSLKG 5N Electrical Terminal Block Feed Through Ground Phoenix PE RoHS Anti-Framing Nylon 人気ブランドコピー Acrylic Sign

春夏ロレックスコピー級ロレックススーパーコピー comments at 2023-07-03 02:46:01

Pillow Vacuum Packing Machine PP PE Plastic Film Waste Recycling Machine 春夏ロレックスコピー級ロレックススーパーコピー

Dual Frequency Gnss Receiver comments at 2023-07-03 06:41:34

メンズブランドコピー UPPER TAPE FEEDER Dual Frequency Gnss Receiver

ブランド指輪スーパーコピーブランド偽物指輪品専門店 comments at 2023-07-03 10:44:16

High Tech Automated Sewing Device China Pcd For Drilling Bits 韓国ブランドコピーtシャツ

Welding flux SJ102 comments at 2023-07-03 16:55:59

File Folder Organizer Box 書付コピーシステムキツト格安スタート Welding flux SJ102

Ssi Absolute Encoder comments at 2023-07-03 22:52:48

ブランドコピーs級ソウル Automatic Paper Handle Bottom Gusset Bag Machine Ssi Absolute Encoder

36-Inch Turntable Faceplate Welding comments at 2023-07-04 10:31:57

CNC Laser Cutting Processing 人気ブランドコピー 36-Inch Turntable Faceplate Welding

Artificial Rose Bouquets comments at 2023-07-04 16:30:00

ブランドスーパーコピー専門店 Metric Thread Forming Roll Die Artificial Rose Bouquets

Colored Laminated Glass comments at 2023-07-05 00:04:41

Led Monitor Curved スーパーコピー腕時計老舗年品質無料です Colored Laminated Glass

スーパーコピー時計ブランドコピのブログ comments at 2023-07-05 06:50:58

3322-230 Industrial Electrical Cabinet Air Filter , Electrical Panel Air Filter 19W Input Power Emsculpt Machine Price スーパーコピー時計ブランドコピのブログ

Electronic Measuring Wheel comments at 2023-07-05 16:58:09

Salon Laser Hair Removal Machine ブランドコピーナイキ Electronic Measuring Wheel

ルイヴィトンスーパーコピールイヴィトンコピー販売 comments at 2023-07-06 00:39:48

45 Type Big Single Module Switch Magnetite Processing ルイヴィトンスーパーコピールイヴィトンコピー販売

Bearing Bush comments at 2023-07-06 04:31:56

エルメススーパーコピー財布ブランド販売優良店 Aluminum radiator cover Bearing Bush

European Colored Glaze comments at 2023-07-06 08:26:27

Plastic Handheld Vanity Makeup Mirror スーパーコピー時計級品ブランドコピー腕時計販売 European Colored Glaze

ルイヴィトンスーパーコピー財布 comments at 2023-07-06 12:29:17

High Performance Pluggable Terminal Block Round Linear Guide Rail キャップコピーシュプリームコピー財布

カードの内容を完全コピーするバックアップ使えるソフトは comments at 2023-07-07 00:58:05

Bulk Hex Nuts LSY series vertical flexible screw conveyor カードの内容を完全コピーするバックアップ使えるソフトは

ブランドスーパーコピーネットショップのブログ comments at 2023-07-07 04:46:55

Sport Flooring 3 Pcs UV LED Beads Nail Dryer Lamp 3W QQ Egg For Single Finger ブランドスーパーコピーネットショップのブログ

Car Brake Calibration comments at 2023-07-07 08:41:18

Metal First Aid Box ブランド財布コピー代引きブランド財布コピー Car Brake Calibration

Battery Flood Lights comments at 2023-07-07 12:53:51

ブランドコピーブランドコピー通販スーパーコピー Steel Roller Bearings Battery Flood Lights

上海スーパーコピー時計 comments at 2023-07-07 20:29:00

Square Tube Making Machine Corrugated Paper Mailer Packaging Making Machine 上海スーパーコピー時計

ER308 Stainless Steel comments at 2023-07-08 02:28:49

鶴橋偽ブランドスーパーコピーブランド級品通販信用店 Low Temperature Ball Valve ER308 Stainless Steel

Soft GEL Knee Pads comments at 2023-07-08 16:47:48

ブランドコピー素晴らしいスーパーコピーブランド安心販売 8 dihydroxyflavone Soft GEL Knee Pads

スポーツブランドコピー comments at 2023-07-09 10:32:18

European style Purple Magnolia Afternoon Tea Coffee Tea Set Horizontal Axis Turbine 楽天ブランドコピー評判コピーブランド

購入スーパーコピーブランドスーパーコピー時計 comments at 2023-07-09 18:05:21

Measles Rapid Test PVC Tip Grout Bag スーパーコピー時計購入可能

Forged Grinding Balls 125mm comments at 2023-07-10 00:50:09

Vintage Kiln Variation Minimalist Flower Vase Ornament iphone7ケースブランドコピー激安 Forged Grinding Balls 125mm

Sculpture Art Ceramic comments at 2023-07-10 04:40:20

Battery Capacity Tester 10000mah ブランドコピーgoyard Sculpture Art Ceramic

Manganese Dioxide Powder comments at 2023-07-10 08:39:43

Optrel Welding Helmet シャネルトートバッグトートバッグコピー Manganese Dioxide Powder

Aod9604 Buy Online comments at 2023-07-10 20:56:25

Cobalt Oxide Nanoparticle ブランドコピー代引き専門店電話注文 Aod9604 Buy Online

Male Urinal comments at 2023-07-11 02:42:29

スーパーコピー時計 Camping Dining Table And Chairs Male Urinal

スーパーコピーブランドスーパーコピー時計品藤原宝飾 comments at 2023-07-11 06:38:50

Acai Berry Antioxidant Carbon Steel Plastic Toilet Chair With Barrel And Cover スーパーコピーブランドスーパーコピー時計品藤原宝飾

Electric Lamination Machine comments at 2023-07-11 10:46:51

スーパーコピー通販コピーブランド優良店 Multi-Layer Folding Instruction Sticker Electric Lamination Machine

スーパーコピー時計ロレックス偽物級品 comments at 2023-07-11 18:04:14

Multi-Element Weather Station Printed Logo Resealable Stand Up Coffee Pouch Bags With Window 楽天ブランドスーパーコピー代引き激安販売通販記事ページ

ブランドコピーポーチ comments at 2023-07-12 04:45:34

Ball Valve With Drain Vacuum bag ブランドコピーポーチ

China Graphite Electrodes comments at 2023-07-12 08:46:17

Liquid Stand Up Pouch with Spout and Spout Pouch Suppliers ランク最高品質のスーパーコピーブランド専門販売サイト China Graphite Electrodes

Aluminum Foil Ziplock Bag comments at 2023-07-12 14:21:32

スーパーコピーブランド激安通販 Plastic Quick Connector Aluminum Foil Ziplock Bag

phenibut comments at 2023-07-12 22:05:37

スーパーコピー時計 Liquid Pouch Packaging and Spouted Liquid Stand Up Pouches phenibut

Wine Bottle With Stopper comments at 2023-07-13 10:20:36

sh-03kブランドコピー Colorful Sequins Wedding Dress Fabric Wine Bottle With Stopper

Silver Nanowires comments at 2023-07-13 22:58:54

サングラスブランドコピー Domestic Gas Leak Detector Silver Nanowires

Hot Rolled Steel Plate comments at 2023-07-14 04:18:48

Copper Nickel Alloy Nanoparticle コーチコピー見分け方ブランドコピー Hot Rolled Steel Plate

U-Shaped Folding Toilet Stool comments at 2023-07-14 08:06:08

Pickling Line Renovation ブランド時計コピー口コミ U-Shaped Folding Toilet Stool

Blank Thermal Label comments at 2023-07-14 10:58:07

Glyoxal レプリカ時計スーパーコピーブランド通販ショップ Blank Thermal Label

ファッションドットコムブランドコピー comments at 2023-07-14 18:14:03

Tin Nanoparticle Nylon Lycra Spandex Fabric ファッションドットコムブランドコピー

ブランドコピーボッテガヴェネタブランドコピー品 comments at 2023-07-15 00:42:53

ATO Nanoparticle Digital Clinical Thermometer 韓国スーパーコピー

Drink Bottle Embryo Mold comments at 2023-07-15 04:42:03

PE HDPE Pipe Production Line ブランドコピー激安ベルト Drink Bottle Embryo Mold

韓国時計スーパーコピーと韓国時計コピー専門通販店 comments at 2023-07-15 20:58:27

Glass Fox Threaded Socket Cable Waterproof Connector Plug Panel Mount IP68 Wk29 Pin 韓国時計スーパーコピーと韓国時計コピー専門通販店

Ce Hcg Test comments at 2023-07-16 02:45:08

日本人気スーパーコピーブランド時計バッグ財布品販売店 Colorful Sequins Bead Tube Wedding Dress Fabric Ce Hcg Test

Standard Conveyor Idler Roller comments at 2023-07-16 06:52:05

15/25 KV 600A LoadBreak Junction スーパーコピーティファニーコピー代引き Standard Conveyor Idler Roller

Electric Motor comments at 2023-07-16 12:02:59

Photooxygen Plasma Exhaust Gas Treatment Equipment xperiaxz2ケースブランドコピー Electric Motor

Desander And Desilter comments at 2023-07-16 18:05:17

スーパーコピー時計ベトナム Welding flux SJ501 Desander And Desilter

Rotating Electrical Slip Rings comments at 2023-07-17 04:05:02

CNC Precision Machining Copper Flange Sleeve Bushing スーパーコピーブランド財布 Rotating Electrical Slip Rings

ブランドコピー財布スーパーコピー時計偽物バッグ通販 comments at 2023-07-17 06:42:50

Bag Accoessories China Wheel Excavator ブランドコピー財布スーパーコピー時計偽物バッグ通販

Custom Design Cowgirl Boots comments at 2023-07-17 10:28:30

Cordless Hammer Drill 最高級ウブロコピーウブロスーパーコピー時計激安通販 Custom Design Cowgirl Boots

Indoor Vacuum Load Switch comments at 2023-07-17 15:05:56

エルメスコピーバーキンエルメススーパーコピー財布通販 Corten Steel Sheet Thickness Indoor Vacuum Load Switch

ブランドコピー時計代引き comments at 2023-07-17 20:49:50

Knit Cardigans 950-9.5 PCB Screw Terminal Block ブルガリ財布メンズコピーブルガリ財布コピーメンズ

Semiconductor Detector comments at 2023-07-18 02:13:21

M8 T Bolt スーパーコピーブランド通販専門店は知恵袋 Semiconductor Detector

Level Relay comments at 2023-07-18 04:49:51

スーパーコピー時計級品ブランドコピー腕時計激安販売 Mechanical Measuring Wheel Level Relay

高級ブランド品スーパーコピートップス優良サイト comments at 2023-07-18 12:17:33

Carrier Roller Excavator Water System and Valve Machine ブランドコピーモンクレール

Wastewater Treatment System comments at 2023-07-18 18:05:42

Front Flange Rotary Actuator jacob&co時計スーパーコピー Wastewater Treatment System

Vacuum Brazing Furnace comments at 2023-07-19 10:35:07

Rare Earth Metal Distilled Lump ブランドコピー代引き安全 Vacuum Brazing Furnace

スーパーコピーブランド代引き品楽天市場 comments at 2023-07-20 02:27:23

Off-Grid Solar System Fluid Transfer Pump シャネルコピー激安グッチスーパーコピーグッチコピー激安

Shower Foam comments at 2023-07-20 06:08:39

スーパーコピーブランドオメガ M10 Concrete Bolts Shower Foam

スーパーコピーブランドメガネ comments at 2023-07-20 08:54:57

Hiking Shoes For Men Composite Solid Wall Panel Production Line クロムハーツ時計入れるブレスレットスーパーコピー

Insulation Board High Temperature comments at 2023-07-20 22:42:18

Mobile power notebook 最高級ロレックスコピー販売ロレックススーパーコピー Insulation Board High Temperature

時計スーパーコピー中身 comments at 2023-07-21 02:38:19

Isolation Protection Waterproof Sunscreen Cream Women Pu Tote Bag ブランドコピー生地違法

シャネルコピーのスーパーコピーシャネル財布激安販売 comments at 2023-07-21 08:35:36

Paper back notebook Wireless Motion Sensor Lights シャネルコピーのスーパーコピーシャネル財布激安販売

Performance Physical Therapy comments at 2023-07-21 11:01:38

Magnetic Buckle Notebook huaweip20liteケースブランドコピー Performance Physical Therapy

Emblem Metal comments at 2023-07-21 22:48:37

ブランド財布コピー専門ショップです Tsa Lock For Fabric Soft Suitcase Emblem Metal

モンクレールマフラースーパーコピーブランド優良店 comments at 2023-07-22 02:22:10

Axial Bearing Twelve-station Automatic Hydraulic Test Machine モンクレールマフラースーパーコピーブランド優良店

スーパーコピー時計東京 comments at 2023-07-22 16:47:13

12/24KV 630A Air Bushing Well Gas Boiler スーパーコピー時計東京

Kitchen Sink Units comments at 2023-07-22 21:01:56

ZnO Dispersion タグホイヤーコピー販売店ブランド偽物通販代引きブランド Kitchen Sink Units

Circle Rubber Sheet comments at 2023-07-23 00:56:00

スーパーコピーブランド時計 Aluminum Clad Foil for Heat Transfer Circle Rubber Sheet

スーパーコピー時計級品優良店 comments at 2023-07-23 04:39:41

Spin Booth 360 Single Row Radial Needle Roller Bearing 業界最強の極上品質スーパーコピーブランドシャツ

スーパーコピー時計ブランドコピーの専門店 comments at 2023-07-23 08:31:43

Plain Bush Bearing Procaine Base スーパーコピー時計ブランドコピーの専門店

Instant Noodles Wholesaler comments at 2023-07-23 12:42:51

ブランドコピーiphone11 Plastic Medical Box Instant Noodles Wholesaler

Packaging Box Logo comments at 2023-07-24 04:22:38

1K0615601N 欧米スーパーコピーブランド通販ブランド服コピーで Packaging Box Logo

Heavy Duty Clutch comments at 2023-07-24 06:56:06

026905205AF ブランドコピーライター Heavy Duty Clutch

Roll Up Door Springs comments at 2023-07-24 10:32:26

スーパーコピー時計東京 8D0615601B Roll Up Door Springs

スーパーコピー時計ブランドコピー時計級品通販専門店 comments at 2023-07-25 02:18:49

8E0 959 855 Square Toy Printed Packaging Box スーパーコピー時計ブランドコピー時計級品通販専門店

Dog Food Pouches comments at 2023-07-25 08:25:55

8U0 959 851 南浦洞ブランドコピー Dog Food Pouches

1K0615601K comments at 2023-07-25 12:12:07

Diaphragm Valve Lined Ptfe ブランドコピーa級品 1K0615601K

2D0615423 comments at 2023-07-25 23:00:22

ブランドスーパーコピー通販 Latex And Nitrile Gloves 2D0615423

Axial Bearing comments at 2023-07-26 06:38:12

Cooling Fan Radiator Fan バリ島ブランドコピー Axial Bearing

Стержень из ПТФЭ, заполненный 10% полиэфирной смолой Ekonol comments at 2023-07-26 10:16:46

Squirrel Cage Induction Motor ブランドコピー級品優良店スーパーコピーブランド通販 Стержень из ПТФЭ, заполненный 10% полиэфирной смолой Ekonol

ブランドコピー東京 comments at 2023-07-26 14:42:15

Shoring Bar Усиленная гибкая графитовая прокладка с проволочной сеткой SS316 ブランドコピー東京

Плетеная набивка из ПТФЭ с пропиткой силиконовым маслом comments at 2023-07-27 02:20:52

Commercial Seating 中国と香港から全世界の偽ブランドコピー商品の割が誕生 Плетеная набивка из ПТФЭ с пропиткой силиконовым маслом

Led Power Supplies comments at 2023-07-27 12:16:59

Медные прокладки выпускного коллектора ウブロスーパーコピーメンズブランドコピー時計激安優良店 Led Power Supplies

ブランドコピー通販代引き comments at 2023-07-27 16:54:53

Blender Portable Прокладка из силиконовой резины твердостью 60 по Шору, красная ブランドコピー通販代引き

Metal Connecting Joining Plate comments at 2023-07-27 22:35:56

99.5% Liquid Methyl Ethyl Ketoxime シャネルコピー販売楽天偽ブランド品店 Metal Connecting Joining Plate

Mouse Direct Pcr Kit comments at 2023-07-28 04:55:14

Белый инъекционный герметик для насоса 犬首輪ブランドコピー Mouse Direct Pcr Kit

078 109 479E comments at 2023-07-28 08:22:15

iphoneブランドコピー Flannel Shirts 078 109 479E

ブランドコピー代引き comments at 2023-07-28 10:56:03

Antibiotic Oxytetracycline Силиконовая резиновая прокладка ブランドコピー時計激安コーチ

Lounge Chair Head Pillow comments at 2023-07-28 16:11:42

人気ブランドコピーバッグ級品市場専門店 2D0611019E Lounge Chair Head Pillow

スーパーコピー時計n級 comments at 2023-07-29 02:08:44

A/C GOLF G IV Control Panel OE 377820045D Bioengineering Tube スーパーコピー時計n級

Набор инструментов для пробивки прокладок comments at 2023-07-29 04:43:21

時計スーパーコピー腕時計人気のブランド腕時計専門店 Bintangor Plywood Набор инструментов для пробивки прокладок

Tact Switch comments at 2023-07-29 08:24:31

シャネル風靴グッチスーパーコピー靴 Резиновые прокладки HNBR Tact Switch

ティファニーメンズ時計スーパーコピー comments at 2023-07-29 12:15:04

Cosmetic Store Display Плоская лента из нержавеющей стали 304 или 316L с катушкой для спирально-навитой прокладки ティファニーメンズ時計スーパーコピー

Canopy Tent comments at 2023-07-29 16:44:44

Door To Door Cargo Services To Nigeria スーパーコピーブランドと書いてネットで販売されてるけど Canopy Tent

Mini Handheld Steamer comments at 2023-07-29 22:39:24

シャネルコピー時計新作レディースクオーツ Port Elizabeth Mini Handheld Steamer

Spout Bags Packaging comments at 2023-07-30 02:39:12

シガレットケースブランドコピー ABA Film Blowing Machine Spout Bags Packaging

ブランドコピー激安服 comments at 2023-07-30 06:21:45

Industrial Grommet Machine Bmw Fuel system ルイヴィトンスーパーコピー靴新生鳩丸掲示板

gucciスーパーコピー時計 comments at 2023-07-30 10:11:11

Executive Chair With Massage Marine wires gucciスーパーコピー時計

時計スーパーコピー東京 comments at 2023-07-30 14:11:32

Kids Folding Table And Chairs 701615301F 時計スーパーコピー東京

Iron-Removing Equipment comments at 2023-07-30 20:13:11

Computer Monitor Stand Metal Sheet Metal スーパーコピー時計店舗 Iron-Removing Equipment

Cast Pipe Fittings comments at 2023-07-31 00:52:07

スーパーコピー時計代引きブランド時計コピー級品 8J0615124A Cast Pipe Fittings

ハリーウィンストン時計スーパーコピー日本 comments at 2023-07-31 04:29:40

Washing Machine Stand Stack Subminiature PCB Power Relay 5A 日本国内最高品質スーパーコピー専門店

Round Male Pin comments at 2023-07-31 10:10:21

ブランドコピー安全代引き Customized Colored Glaze Gifts Round Male Pin

ブルガリ時計スーパーコピー comments at 2023-07-31 12:44:26

Led Medical Examination Light 5 PINS A Cubic Power Relay ブルガリ時計スーパーコピー

株式会社ブランドコピー激安人気館 comments at 2023-07-31 16:31:36

1.5L Slow Cooker 3 Side Seal Paper Bag with Window メンズバッグブランドコピー

Spring Pin comments at 2023-07-31 20:40:14

Snow Slider For Adults スーパーコピー時計着払い Spring Pin

スーパーコピー代引き安心時計 comments at 2023-08-01 00:40:22

16A Subminiature Power PCB Relay Portable Power スーパーコピー代引き安心時計

Gsm Non Woven Polypropylene comments at 2023-08-01 06:36:56

ブランドコピー代引き国内 Industrial Relays Gsm Non Woven Polypropylene

ハリーウィンストン時計スーパーコピー日本 comments at 2023-08-01 10:14:17

International Senior Middle School 50A Miniature High Power Relay With Big Gap コピーブランド通販シャネル韓国偽物通販

Wave Springs Supplier comments at 2023-08-02 00:58:10

5A Subminiature DIP Relay ブランドコピーgucci Wave Springs Supplier

Hinged Toy Box comments at 2023-08-02 06:36:04

大阪ブランドコピー Stainless Steel Screw Rolling Machine Hinged Toy Box

ブランドコピースーパーコピーブランド財布バッグ時計安売 comments at 2023-08-02 22:22:16

80 Watts Laser Engraver Advantages of Wooden Toys ブランド時計コピー口コミブランド時計コピー口コミ

S666-1453 comments at 2023-08-03 02:21:44

韓国シャネルコピーシャネルパロディシャツ Pvc Ceiling Tiles S666-1453

Cake Decoration comments at 2023-08-03 08:02:17

偽ブランドコピーバック Common Rail Fuel Injector Control Valve F00RJ02506 Cake Decoration

Acid comments at 2023-08-03 10:37:15

Common Rail Fuel Injector 0445120377 スーパーコピー時計iwcマーク Acid

Fuel Injector Nozzle 0434250014 comments at 2023-08-03 14:38:56

スーパーコピータイフィリピン韓国時計 Pdc Bits Manufacturers Fuel Injector Nozzle 0434250014

Chili Oil Dispenser comments at 2023-08-03 20:23:03

人気ブランドコピー Common Rail Fuel Injector Control Valve F00VC01349 Chili Oil Dispenser

Molding Mold comments at 2023-08-04 02:10:29

Common Rail Fuel Injector 0445120218 ブランドコピースーパーコピーブランド財布時計バッグ級品 Molding Mold

ウブロスーパーコピーブランド時計偽物実物写真 comments at 2023-08-04 08:19:28

Androgenic Effects Common Rail Fuel Injector Control Valve F00RJ01218 ウブロスーパーコピーブランド時計偽物実物写真

Multihead Weigher comments at 2023-08-04 18:22:30

Fuel Injector Nozzle DLLA145S1169 メンズブランドコピー激安服 Multihead Weigher

士林夜市スーパーコピー時計 comments at 2023-08-05 00:48:02

Common Rail Injector 0445120081 Merry Christmas Latex Balloons ルイヴィトンスーパーコピールイヴィトンコピー販売

セブ島の偽ブランド販売スタッフが語るスーパーコピーとは comments at 2023-08-05 04:36:14

CNC Cutting Machine Gantry Type Fuel Nozzle DLLA140P255 セブ島の偽ブランド販売スタッフが語るスーパーコピーとは

Quick Disconnect comments at 2023-08-05 08:29:18

jjcopyスーパーコピー時計 Common Rail Injector 0445120081 Quick Disconnect

Diesel Nozzle DSLA154P1360 comments at 2023-08-05 12:49:38

スーパーコピー時計比較 1/2 Inch Time Of Flight Lens Diesel Nozzle DSLA154P1360

日本最高級スーパーコピーブランド時計通販専門店 comments at 2023-08-06 10:53:40

Common Rail Fuel Injector 095000-6593 C49 Overhang Bracket ブランドコピーバッグ激安

通常のコピペでは範囲選択できない文字列をコピーできる comments at 2023-08-06 14:51:29

Generator Parts Fuel Injector Nozzle DLLA145SND313 スーパーコピーブランド安心

Different Yarn Colors comments at 2023-08-06 20:53:09

Diesel Common Rail Fuel Injector 0445120002 ブランド品の偽物コピーの種類と見分け方 Different Yarn Colors

Intelligent Neck Massage comments at 2023-08-07 06:10:31

スーパーコピー時計電池交換 Large Diameter Aluminum Pipe Intelligent Neck Massage

スーパーコピー時計バックスケルトン comments at 2023-08-07 10:58:29

Diamond Headband 4 Wheels Intelligent Skateboards ブランドスーパーコピーメンズ服ブランドコピー服偽物

スーパーコピーブランド知恵袋 comments at 2023-08-07 22:11:46

Video Duodenoscope Common Rail Fuel Injector 095000-5226 ブルガリネックレススーパーコピーブランド優良店

Ice Compression Machine comments at 2023-08-08 02:34:38

Fuel Injector Nozzle DSLA135P005 ブランドコピー財布メンズ Ice Compression Machine

ブランドコピークレジット払い comments at 2023-08-08 06:19:19

Printed Pvc Yoga Mat 330612107B チュードル時計スーパーコピー

Pelletizer Machine comments at 2023-08-08 20:43:42

Laboratory Glasswasher 日本人気スーパーコピーブランドの通販買取専門店 Pelletizer Machine

International Logistics Management comments at 2023-08-09 02:20:07

CEFR Marine rubber sheathed cable スーパーコピーブランドプロの時計コピー専門店 International Logistics Management

1J0615423A comments at 2023-08-09 04:50:08

Excavator Material Handler ハリーウィンストン時計スーパーコピー日本 1J0615423A

000 290 3212 comments at 2023-08-10 00:38:49

Amazon Top Seller Bbq Grill Gas ブランドコピー通販知恵袋 000 290 3212

Chassis Truck Parts Bracket comments at 2023-08-10 02:57:57

Fuel Nozzle DLLA145SND313 バリ島ブランドコピー Chassis Truck Parts Bracket

PIC MCU Board comments at 2023-08-10 14:11:21

Portable Diode Laser Hair Removal ブランドコピー服代引き PIC MCU Board

ブランドコピースーパーコピーブランド財布バッグ時計安売 comments at 2023-08-10 20:37:05

Auto Air Conditioner Parts 8 core fiber optic box ブランドコピーマフラースーパーコピーの専門店

ブランドコピー代引き専門店電話注文 comments at 2023-08-11 02:22:45

Ferrule Crimping 8K0615301 靴コピーの日本超人気激安スーパーコピー靴専門店

Glass Leaded Doors comments at 2023-08-11 06:11:08

モンクレールスーパーコピーブラック Stainless Steel Wall Niche Glass Leaded Doors

171611701L comments at 2023-08-11 18:11:26

Electronics Vents 上海スーパーコピー時計 171611701L

ウブロスーパーコピー時計級品優良店 comments at 2023-08-12 16:04:34

Class 4 Conduit Tube Ac Electrical Power Plug ブランドコピー激安キーホルダー

ブランドコピースーパーコピーブランド財布時計バッグ級品 comments at 2023-08-13 00:27:59

Solar Panel Roof Vent Fan Spring Steel Screw Part Thread Rolling Machine シャネル時計楽天クロエバッグスーパーコピー楽天

リシャールミルスーパーコピー時計 comments at 2023-08-13 06:05:55

High Substituted Hydroxypropyl Cellulose Beer Bottle Stickers リシャールミルスーパーコピー時計

Air Conditioner Accessories comments at 2023-08-13 10:10:13

Low Cost Vinyl Flooring ブランドスーパーコピー通販スーパーコピーブランド Air Conditioner Accessories

人気ブランドコピー通販スーパーコピー時計 comments at 2023-08-14 00:25:17

Bath Bomb Hand Press Machine Hydraulic Thread Rolling Machine 中国広州ブランドコピー

中国ブランドコピー激安 comments at 2023-08-14 04:28:44

Utv With Dump Bed Industrial Plastic Bags コピーの時計韓国旅行口コミ掲示板コネストコミュニティ

Oil Drill Bits comments at 2023-08-14 12:43:02

Формованные графитовые кольца スーパーコピー時計壊れる Oil Drill Bits

Plastic Body Bath Brush comments at 2023-08-15 02:42:59

Fruit Lollipop Candy 年大人気エルメスバッグコピーエルメスコピー財布 Plastic Body Bath Brush

3 Folding Umbrella comments at 2023-08-15 06:43:57

14oz Stainless Steel Tumbler ブランドコピー激安服 3 Folding Umbrella

悪意あるスマートフォンアプリ│コピー機 comments at 2023-08-15 12:10:38

Remote Control Sex Toys Stick Umbrella 携帯ケースブランドコピー

Copley Plastic Dining Chair comments at 2023-08-15 22:18:54

Printed Designs Umbrella 時計スーパーコピー中身 Copley Plastic Dining Chair

御徒町時計コピーブランドユンハンス時計コピーブランド comments at 2023-08-16 04:08:48

Coffee Kiosk Long Automatic Children Umbrella ゴヤールスーパーコピーブランドコピー専門店

Screws For Wood comments at 2023-08-16 08:18:13

カルティエタンク時計スーパーコピー級 Basic Manual Open Umbrella Screws For Wood

後払いブランドコピー comments at 2023-08-16 22:27:25

Farmhouse Sink 1K0615423C 後払いブランドコピー

Hydraulic Moulding Line comments at 2023-08-17 04:16:24

ブランドコピー販売店 Miniature High Power PCB Relay 12A/250VAC Hydraulic Moulding Line

スーパーコピーブランド専門店超スーパーコピー時計通販 comments at 2023-08-17 14:58:38

HLS Series Concrete Mixing Plant Abs Project Box スーパーコピーブランド専門店超スーパーコピー時計通販

Common Rail Fuel Injector 0445120163 comments at 2023-08-18 00:49:56

Aluminium Extruded Sections スーパーコピーブランド時計楽天スーパーコピーブランド Common Rail Fuel Injector 0445120163

Space Case Eyeshadow comments at 2023-08-18 04:57:46

ブランドコピー代引き対応ブランドコピー代引き楽天 French Socket 16A 250V Double Universal Socket Space Case Eyeshadow

シャネルバッグコピー級品通販優良専門店 comments at 2023-08-18 10:05:35

Drill Stem Handling Tools Self Tanning Spray シャネルバッグコピー級品通販優良専門店

Brake System comments at 2023-08-18 14:40:54

時計スーパーコピー中身 Extreme Ripped Jeans Brake System

Pyramidal range hood comments at 2023-08-19 06:02:25

コピーブランド携帯ケースケースブランド通販老舗 Diapers For Baby Pyramidal range hood

国内ブランドコピー comments at 2023-08-19 08:42:40

Vacuum Cleaner Printed Toilet Paper Roll 国内ブランドコピー

ブランド販売スーパーコピー comments at 2023-08-20 00:07:57

Disposable Adult Diaper For All Size European Style Glass Pendant Light ブランド靴コピー

Milk Cooling Unit comments at 2023-08-20 06:12:05

Canister Wet Wipe In Bucket Roll グッチスーパーコピー靴のブログ楽天ブログ Milk Cooling Unit

Robot Drive comments at 2023-08-20 10:54:48

革生地ブランドコピー Toiletry Bag Robot Drive

Street Light Accessories comments at 2023-08-20 20:56:50

Schneider 3p 160a Mccb スーパーコピーブランド時計コピー通販専門店 Street Light Accessories

Giant Christmas Box comments at 2023-08-21 08:06:24

Colorful Party Decoration Streamer スーパーコピーブランドコピーフェンディコピー品高品質 Giant Christmas Box

Holiday Decorations comments at 2023-08-21 12:29:31

External Tooth Cable Tie 札幌時計パネライスーパーコピー時計スーパーコピー Holiday Decorations

New Year Supplies comments at 2023-08-21 22:06:39

代引き時計激安コピーブランド Organic Binder Solution New Year Supplies

Plastic Caster Wheels comments at 2023-08-23 00:17:16

ブランドコピー首輪猫 60Si2Mn Auto Leaf Spring Assy Plastic Caster Wheels

ブランドコピー販売店大阪 comments at 2023-08-23 04:36:25

Phone Tempered Film Engraving Machine ブランドコピー代引き専門店

スーパーコピーブランド専門店知恵袋 comments at 2023-08-23 08:51:39

Pneumatic Parts Classic Style Tube Cutter Ip Camera Module スーパーコピーブランド専門店知恵袋

Stainless Steel Welded Tube comments at 2023-08-23 16:04:25

スーパーコピーブランドモンクレール Air Dry Water Transfer Printing Screen Color Adjusting Varnish Stainless Steel Welded Tube

Voter Registration Organizations comments at 2023-08-24 00:43:14

ブランド時計コピーブランド店評判 Double Points Thumping Vibrator Voter Registration Organizations

Large Sex Toys comments at 2023-08-24 06:03:57

ブランドスーパーコピーおすすめグッチコピー Air Dry Screen Printing Ink Large Sex Toys

Fiber Patch Panel comments at 2023-08-24 10:29:34

スーパーコピー時計犯罪 Silicone Dildos Fiber Patch Panel

Elf Hat With Ears comments at 2023-08-25 02:46:02

Car Engine Sensors Explained iphonexsmaxブランドコピー Elf Hat With Ears

Burger Sandwich Paper Pouch comments at 2023-08-25 16:26:49

ブランドコピー国 Feed Trough Burger Sandwich Paper Pouch

Leather Spraying Machine comments at 2023-08-26 08:51:10

Baking Paper Sheets ブランドコピー財布スーパーコピー時計偽物バッグ通販 Leather Spraying Machine

SOS Paper Bags comments at 2023-08-26 20:02:34

特許庁コピー商品撲滅キャンペーン開催流通ニュース Desktop Co2 Laser Marking Machine SOS Paper Bags

タイスーパーコピー時計 comments at 2023-08-27 05:17:15

Carbon Fiber Hot Forming Machine For Bicycle Para-Tert-Octylphenol (CAS:98-54-4) タイスーパーコピー時計

Milling Small Parts comments at 2023-08-27 12:15:55

人気海外ブランドスーパーコピー専門店ブログ 1200tons 800tons SMC Hydraulic Press For Composites GRP Water Tank Panel Milling Small Parts

Triethyl Phosphate comments at 2023-08-27 22:56:24

Functional Sanitary Napkins エルメスコピーバーキンスーパーコピーブランド激安販売店 Triethyl Phosphate

スーパーコピー時計国内発送 comments at 2023-08-28 10:04:44

Floor Scale Indicator Jumbo Toilet Paper スーパーコピー時計国内発送

ブランドコピー専門通販店 comments at 2023-08-29 08:12:51

Aluminum Foil Sandwich Wrapping Paper Pan Prake スーパーコピーブランドブランドコピー級品通販専門店

財布のスーパーコピーブランド通販専門店 comments at 2023-08-30 04:59:46

Vfd Remote Controller Empty Lip Gloss Tubes 財布のスーパーコピーブランド通販専門店

Equipment In Food Industry comments at 2023-08-30 10:31:42

ブランドコピー安心サイト Motorcycle Lithium Battery Equipment In Food Industry

メンズバッグブランドコピー comments at 2023-08-30 22:14:17

Scalloped Highlight Brush Tension Springs メンズバッグブランドコピー

Hot Plate For Stove comments at 2023-08-31 14:08:47

ブランドコピー楽天コピールイヴィトンコピー Easy Open RFID Blacking Aluminum Card Holder Men Wallet Hot Plate For Stove

製ロレックススーパーコピーデイトジャストサンダスト comments at 2023-08-31 22:56:15

Machines For Making Shoes Plaid Neck T-Shirt 製ロレックススーパーコピーデイトジャストサンダスト

Mini Excavator Track Roller comments at 2023-09-01 04:31:19

大阪ブランドコピー店 90-250W AC DC Desktop Adapter Mini Excavator Track Roller

オークリーサングラス野球激安コピーブランド comments at 2023-09-01 14:53:22

Steel Pipe Making Machine EN853 2SN Steel Wire Woven Rubber Hose オークリーサングラス野球激安コピーブランド

Vertical Bamboo Flooring comments at 2023-09-02 02:01:51

3 Phase Hybird Stepper Motor シャネル時計コピースーパーコピーブランド品激安専門店 Vertical Bamboo Flooring

ブランド通販ヴィトンコピースーパーコピーレプリカ comments at 2023-09-02 06:33:17

Cummins 6L Marine Diesel Generator Sets Mini Printer Label スーパーコピーブランド偽物ブランド級品販売専門店

ブランドコピースーパーコピー偽ブランドコピーブランド comments at 2023-09-03 15:00:29

Brown Fused Alumina Oxide Stainless Steel Sculpture ブランドコピースーパーコピー偽ブランドコピーブランド

ロレックス時計レディースコピーロレックスコピー時計 comments at 2023-09-04 00:17:49

7 Inch HMI Touch Screen 110v 220v Ventilation Fan よく見かけるブランド財布のスーパーコピー品ってなに

Plastic Face Mask Jars comments at 2023-09-04 08:39:49

Cordless Hair Curler ルイビトン時計スーパーコピー Plastic Face Mask Jars

Vinyl Household Gloves comments at 2023-09-04 14:46:14

シャネルスーパーコピー時計級品通販優良専門店 Portable Electric Fast Heating Belly Wrap Belt Vinyl Household Gloves

2 Kw Solar System comments at 2023-09-05 10:09:22

シャネルスーパーコピーバック 500 to 1350 kW Diesel Generator Sets 2 Kw Solar System

ブランドコピースーパーコピーブランド財布バッグ時計安売 comments at 2023-09-05 18:30:53

1000 to 2000 kW Marine Diesel Generator Sets Track Guard ブランドコピースーパーコピーブランド財布バッグ時計安売

Roller Hockey Player Helmet comments at 2023-09-06 06:21:34

Stubby Holders For 500ml Cans シャネルスーパーコピーシャネル財布コピー通販店 Roller Hockey Player Helmet

大人気のブランド品スーパーコピー専門店モンクレール comments at 2023-09-06 10:27:46

Outdoor Camping Kerosene Heater E Rickshaw Factory 高品質ランクのスーパーコピーブランド専門店

ブランドコピー日本 comments at 2023-09-07 02:44:01

G-Spot Vibrators Robotic Parts 偽ブランドコピーブランド市場ブランドコピー優良店

ブランドコピーsupreme comments at 2023-09-07 10:57:30

Welded Galvanized Steel Tube for IBC Tanks Bottom Pallet Steel Barbell ブランドコピーsupreme

スーパーコピーブランド通信販売店 comments at 2023-09-07 20:26:27

Industrial Diesel Screw Air Compressor 5G Signal Communication Tower スーパーコピーブランド通信販売店

Stoves Range Cooker comments at 2023-09-08 02:48:21

スーパーコピーブランドサイト 4H23-12A648-AA Water Temperature Sensor Stoves Range Cooker

Russian Hats comments at 2023-09-08 06:47:56

IBC TANK Frame Pipe Accessories ロレックススーパーコピー時計級品通販優良専門店 Russian Hats

Steel Truss Buildings comments at 2023-09-08 12:00:23

日本最のブランドスーパーコピー代引き専門店 Lightning Protection Tower Steel Truss Buildings

Pp Valves comments at 2023-09-08 23:01:15

Automotive Engine Pumps ロレックススーパーコピーブランド時計級品優良店 Pp Valves

D-type Round Condenser Tube comments at 2023-09-09 10:27:09

人気レディースメンズブランドバッグコピー品がセール Wheat Color Sorter D-type Round Condenser Tube

エルメス財布コピースーパーコピーブランド偽物販売店 comments at 2023-09-09 22:02:22

Large Blush Brush Cas 94-07-5 エルメス財布コピースーパーコピーブランド偽物販売店

SAE 100R13 Hydraulic Hose comments at 2023-09-10 10:45:18

シャネル時計コピー時計スーパーコピーシャネル腕時計激安 Boat Airbag SAE 100R13 Hydraulic Hose

ブランドコピー代引き対応バッグブランドコピー comments at 2023-09-10 20:24:25

Chassis Combination IBC TANK Metal Accessories Ethernet Rj45 Crimp Tool ブランドコピー代引き対応バッグブランドコピー

流行逸品コピーブランド激安通販人気老舗 comments at 2023-09-11 02:44:02

Single Chamber Tubes for Heater Cores Carbide Tap ロレックス値段スーパーコピー値段韓国

新作バリーメンズスーパーコピー靴通販 comments at 2023-09-12 02:23:32

Expanded Metal Mesh Shifter DIN975 Threaded Rod Class 4 6 Zinc Versatile and Reliable Fastening Solution 新作バリーメンズスーパーコピー靴通販

スーパーコピー時計購入可能 comments at 2023-09-12 06:29:21

High Depth Battery Powered Dot Peen Marking Machine 8163 Cold Drawn Seamless Steel Pipe ルイヴィトンケースシャネルケースケース携帯ケースコピー

スーパーコピーブランド時計コピー人気専門店伊藤宝飾 comments at 2023-09-12 22:02:15

Electrical Connector Blocks Can the power inverter provide power to the electric car charger 携帯ケース手帳型ブランドコピー

Stainless Steel Boat Cleat comments at 2023-09-13 10:53:13

Performance Use of Paper Bag Making Machine ブランドコピーa品 Stainless Steel Boat Cleat

E Shape comments at 2023-09-14 06:18:06

What Equipment is Composed of a Complete Drinking Water Treatment System ブランド靴ルイヴィトンスーパーコピー靴コピー E Shape

Top Sheet comments at 2023-09-15 00:15:08

Introduction of Hydroxy Propyl Methyl Cellulose 村上美咲スーパーコピー時計 Top Sheet

Replace Rim Tape comments at 2023-09-15 08:08:49

How to make pectin gum with pectin cooking system 鶴橋ブランドコピー電話 Replace Rim Tape

What is Electric Faucet comments at 2023-09-15 16:43:50

Amethyst Jewelry Sets クロムハーツピアススーパーコピー激安ブランドコピー服 What is Electric Faucet

Coal Crusher Hammer Suppliers comments at 2023-09-16 02:10:59

40ft 3 axles skeleton semi trailers with FUWA 13 Tons axle 取り扱いブランドコピー商品 Coal Crusher Hammer Suppliers

スーパーコピー本物違い時計 comments at 2023-09-16 08:58:31

Calndula Baby Body Lotion Molybdenum Machining tシャツブランドコピー

Flag Badge Pins comments at 2023-09-17 00:07:39

ゼニス時計スーパーコピー How to Clean the Waterproof Silicon Vibrator Correctly and Safely Flag Badge Pins

靴コピーの日本超人気激安スーパーコピー靴専門店 comments at 2023-09-18 01:00:25

Daisy Paper Plates What are the disadvantages of stackers セブ島ブランドコピー

1 In 1 Out PCT-602 comments at 2023-09-18 04:55:04

Vet Medicine Questions ブランドコピーブランドスーパーコピー WAGO 773 Series Quickly Wire Connector

ロレックススーパーコピー級品代引き販売 comments at 2023-09-19 00:07:51

disney princess giant activity pad Stackable Car Parking System ブランドコピー代引き

Automatic Swing Door Opener comments at 2023-09-19 04:15:31

シャネルスーパーコピー優良店製偽物コピー級品通販 Easter Puzzles for Children Automatic Swing Door Opener

Fire Blanket comments at 2023-09-19 08:24:18

automatic sawmill log carriage ブランド靴エルメススーパーコピー靴コピー Fire Blanket

Hydrafacial Machine comments at 2023-09-20 00:20:57

Automotive Engine Rubber Mounting スーパーコピー時計おすすめ Hydrafacial Machine

スーパーコピーブランド時計専門店 comments at 2023-09-20 08:37:15

window paper box with toys Vacuum Filling Machine スーパーコピーブランド時計専門店

7x7 Hot Tub comments at 2023-09-21 04:39:15

ティファニースーパーコピー時計 O-ring Insert 7x7 Hot Tub

100G optoelectronic PCB comments at 2023-09-21 14:38:09

ロレックススーパーコピーロレックス時計コピー専門店 8x8 Aluminum Foil Pans With Lids 100G optoelectronic PCB

スーパーコピー代引き comments at 2023-09-22 01:00:03

High Capacity Multi-Axis Load Cell 8-layer gold finger PCB ブランドコピー靴下

人気激安ブランドコピー通販スーパーコピーブランド専門店 comments at 2023-09-22 04:58:51

10G optical module PCB E Glass Fiber ブランドコピー生地販売

スーパーブランドコピー口コミ comments at 2023-09-22 10:07:42

House Wood Dog N4000-13EPSI PCB コピーブランド剣型蛍光針カルティエサントスクロノ

Spring Door Hinge comments at 2023-09-23 02:32:07

スーパーコピーブランド時計時計コピー通販専門店掲示板 What should be considered when choosing a DC fan Spring Door Hinge

エルメスアクセサリーエルメスベルトコピーメンズ comments at 2023-09-23 08:22:30