|

|

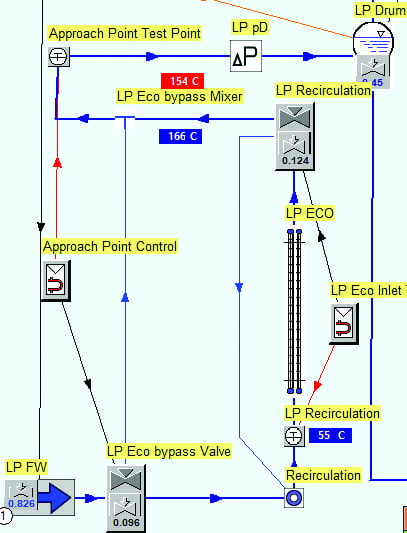

3. This image shows the low-pressure economizer water scheme in more detail. The approach temperature is shown in the red box taken from the test point before entering the drum. In this iteration, the temperature was 154C, which corresponds to an approach point of 8C. Courtesy: Tetra Engineering Group Inc. |

The HRSG simulation was set up as described previously. Once the inlet flue gas, heating surfaces, drums, and steam turbine were all input, the output was compared to guarantee design cases. Furthermore, DCS data from the plant was used for the final adjustments to ensure the simulation was as close as possible to actual operating conditions. At the time of the assessment, the plant was operating the HRSG with an 8C LP approach temperature. Three load cases were prepared corresponding to 100%, 75%, and 45% GT loads.

The main advantage of having an accurate simulation of a boiler or HRSG is that the impact of certain parameters can be investigated with no repercussions on pressure part or equipment integrity. In the context of this project, different test cases were run with approach temperatures ranging from the original 8C to 1C. The approach temperature of 0C was not considered as flashing upstream of the drum would occur. The emphasis of these test cases was to assess the impact on the integrity of the LP economizer, piping, and valves.

The main risks induced by lowering the approach temperature are the following:

- ■ Steaming in the economizer. If water evaporates in the economizer, this could lead to disruptions of the flow, deposit formation, vibrations, and flow stagnation, leading to tube-to-tube differential expansion.

- ■ Flashing to steam across the drum level control valve (LCV) and LP economizer recirculation valve, causing severe erosion through cavitation.

The material properties of all the susceptible components were reviewed and it was concluded that these would be able to withstand the increase in temperature.

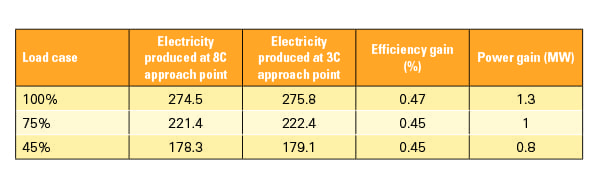

Lowering the approach temperature allows the water entering the drum to be closer to saturation, and therefore, speeds its evaporation to steam. This means a lower evaporator circulation ratio (amount of circulation required for incoming saturated water to evaporate) in the drum is required, leading to an increased steam production. As expected, using an approach temperature of 1C or 2C led to the highest efficiency gain. However, industry practice is to keep the approach point greater than 3C to give more room for error regarding control instrumentation and operating uncertainty. Decreasing the approach temperature from 8C to 3C resulted in a 0.8 MW to 1.3 MW power increase, depending on the load case (Table 1).

|

|

Table 1. This table shows the power output and efficiency gain using a 3C approach point. Courtesy: Tetra Engineering Group Inc. |

The simulation demonstrated that there are no major risks to component integrity when using an approach temperature of 3C and it was predicted that this would lead to an increase in power production of approximately 1.3 MW at 100% GT load. Assuming a price of $38/MWh (which was the average annual wholesale price of electricity in the U.S. in 2017, according to the U.S. Energy Information Administration) and 8,000 operating hours per year, a 1-MW increase would represent a net financial gain of $304,000 per year.