In the 1950s, temperature-equalizing columns were commonly used in steam drum differential pressure–based devices for measuring water level. However, these columns are problematic because a portion of the reference leg can flash to steam on a pressure decrease (load increase), and this will result in a temporary, false, high-level measurement, which adds to the swell effect. The columns can also result in measurement inaccuracies. It’s time to replace these antiquated instruments with a more modern reference leg.

One of the most critical measurements made at a utility power plant is the water level in the boiler steam drum. A variety of devices are typically used to monitor this drum water level. Differential pressure–based level devices (and even sight glasses) experience measurement inaccuracies when steam drum pressure is not at its design value. These changes in pressure can be overlooked for boilers operating at lower pressures, but for most utility boilers, and many industrial boilers, these inaccuracies should be corrected. One good source of information on this subject is the ISA Technical Report ISA-TR77.42.02-2009, Fossil Fuel Power Plant Compensated Differential Pressure Based Drum Level Measurement.

Steam Drum Level Measurement Overview

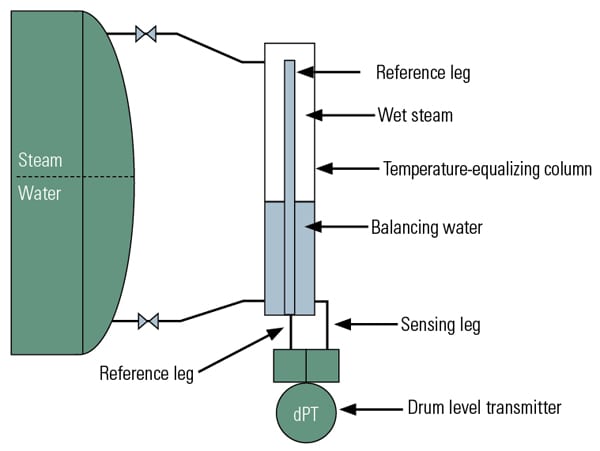

A typical steam drum differential pressure–based level measurement installation is shown in Figure 1. The drum level transmitter in the figure senses the differential pressure between the lower drum measurement tap and the top measurement tap. Because the drum is filled with steam, and there is no flow through the sensing lines, the steam will condense in the reference leg and fill that leg with water. This means that the transmitter is really comparing the difference in pressure between the height of water plus the height of steam in the drum at the saturation temperature and pressure with the height of water in the reference leg at saturation pressure, but at ambient or near-ambient temperature. This difference in differential pressure is also called displacement. Because the only time the temperatures are equal is when the drum is cold, the measurement will only be correct at either that ambient temperature or at the ambient temperature and drum pressure combination at which the transmitter is calibrated.

By the 1950s, drum level differential pressure was measured by purely mechanical means. Many of the measurement devices of that time were mechanical floats on mercury manometers that were in direct contact with the process fluids. The float, with the help of linkage, turned a spindle. After going through a pressure packing and gland, the spindle drove a mechanical pointer. The mechanical pointer would typically be connected to a pneumatic device that could generate a control output directly or send a pneumatic signal to another location.

A typical device of this nature was the Bailey LH level mechanism. These devices worked well but required regular cleaning and calibration because they relied on purely mechanical means to indicate levels. These devices also could have a significant displacement associated with them, and that was the reason for the reservoir (also called a condensate pot) on the reference leg (see Figure 1). Modern differential pressure transmitters with no (or insignificant) displacement do not require this reservoir.

|

| 1. On the level. A typical differential pressure–based drum level transmitter installation. Source: Southern Co. |

The Need for Measurement Compensation

A limitation of the purely mechanical level measurement devices was that in their basic configurations they could not compensate for changes in steam drum pressure or ambient temperature. These pressure- and temperature-related inaccuracies in measurement were usually addressed by calibrating the drum level transmitter so that it was correct for the drum normal operating pressure and for an assumed ambient reference leg temperature (usually 100F). This was usually good enough for lower drum pressure applications, but as steam drum pressures increased, mechanical solutions had to be found to better deal with this phenomenon.

A number of manufacturers addressed this problem with a two-pronged approach. To accommodate changing drum pressures, the differential pressure measurement device would also need to include a pressure measurement bourdon tube or helix coil. This additional device was connected to linkage that used drum pressure to change the gain applied to the spindle-induced movement of the level measurement pointer. The Bailey LH meter used a Class 13H helix coil compensator mechanism for pressure compensation. Yarway Corp. used a bourdon tube in its pointer gauges to perform the same function.

To address issues with changing ambient temperatures, manufacturers developed enhanced versions of the reference leg reservoir. These enhanced reservoirs were known as temperature-compensated reference columns, temperature-equalizing columns, or temperature-compensated constant head chambers. Other manufacturers may have had other names for these devices, but for the purpose of this article they will be referred to as temperature-equalizing columns.

Concerns About Temperature-Equalizing Columns

Many of these temperature-equalizing columns can be problematic because during boiler operation they keep the reference leg at a high temperature. As a result, a portion of the reference leg can flash to steam on a rapid pressure decrease (load increase), and this reaction will result temporarily in a false high-level measurement, which adds to the boiler swell effect. The design of some of the columns may have been less susceptible to this flashing phenomenon because the intent was to keep the column at a constant temperature, meant to be somewhat less than the drum saturation temperature. Measurement inaccuracy can also be related to the use of these columns because the temperature of the reference leg requires an assumed temperature.

Manufacturers began discontinuing sale of these instruments in the 1960s, but they can still be found in service in many power plants. Temperature-equalizing columns of two different manufacturers were found in the piping for two of the steam drums at one of our Southern Co. facilities. Photographs of these devices, with the insulation removed, are shown in Figure 2.

|

| 2. Golden oldies. A 1950s vintage temperature-equalizing column from Yarnall-Waring (Yarway) on the left and Republic Flow Meters on the right. Courtesy: Southern Co. |

Pressure Compensation Equation

For all types of steam drum differential pressure (dP)–based level measurements, the dP measured by the level transmitter is inversely related to the level of water in the steam drum. As the water level goes up, the sensing leg water column approaches the height of the reference leg water column. When the water level in the steam drum reaches the same elevation as the top of the reference leg, the two legs will be the same height, and there will be a differential pressure of zero between the two legs of the transmitter if the legs are both at the same temperature (Figure 3). But, as stated previously, these legs are not usually at the same temperature for steam drum level measurements, and that is the primary source of the error related to this measurement technique.

|

| 3. Measuring different water weights. Steam drum level measurement specific weight differences will cause errors in boiler water elevation measurement if they are not corrected. Source: Southern Co. |

Using the arrangement shown in Figure 4, the differential pressure measured by the steam drum level transmitter is represented by the following equation:

dP = (H x Wwo) – [(Hw x Wwd) + (Hs x Wsd)]

_______________________________

Ww

where:

dP = transmitter-measured differential (H2O)

H = height of the reference leg between the taps (inches)

Hs = height of the column of steam in the drum (inches)

Hw = height of the column of water in the drum (inches)

Wsd = specific weight of steam at drum saturation pressure (lb/ft3)

Wwd = specific weight of water at drum saturation pressure (lb/ft3)

Wwo = specific weight of water in the reference leg between the taps (lb/ft3)

Ww = specific weight of water at 68F that is used to calibrate the transmitter (lb/ft3)

This formula, the basis for the boiler steam drum pressure compensation algorithms that are available for use in most digital control systems, illustrates that the specific weight of the water in the reference leg (Wwo) is an important part of the compensation calculation. Figure 4 illustrates the actual water and steam conditions when a particular type of temperature-equalizing column is used to develop the reference leg for the differential pressure measurement. Figure 4 is representative of past temperature-equalizing column designs of Bailey Meter Co. and Republic Flow Meters.

In Figure 4, the water in the temperature-equalizing column that surrounds the lower part of the reference leg is in balance with the water in the steam drum. Water may seek its own level; however, in this specific application the water in the column is somewhat cooler than the water in the drum, so it will take a shorter column of this cooler water to be in balance with the water in the drum.

|

| 4. Getting a leg up on pressure measurement.Temperature-equalizing column steam and water conditions. Source: Southern Co. |

Of course, plant operators would want to insulate the lines connecting the temperature-equalizing column to the drum. However, if they were to do a really good job of insulating the column itself, the steam would probably never condense to form the desired reference leg, or the height of the reference leg would be constantly changing with pressure and would become unpredictable. Each manufacturer of these columns had its own specific requirements for column insulation.

Because the temperature-equalizing column is somewhat cooler than the drum, the steam that sits over the balancing water in the figure is wet steam (of a low steam quality). The steam is wet because that steam’s pressure is the same as the pressure in the drum, but the temperature is less than saturation temperature; basically, it is raining in the column in the space above the balancing water.

This wet steam condition doesn’t have much impact on the pressure compensation equation because the water and steam in the column is in balance with the water and steam in the drum, so the sensing leg pressure at the drum level transmitter should still be representative of the level of water in the steam drum. The unknown in the pressure compensation equation is the temperature of the reference leg. An assumption must be made as to what this reference leg temperature is, and that assumption must be made based on the design of the temperature-equalizing column.

Reducing the Measurement Error

Bailey Meter Co. and Republic Flow Meter column designs and insulation approaches were to keep the reference leg as close to saturation temperature as practical. In contrast, the Yarway Corp. design and insulation approaches were quite a bit different, as that company’s philosophy was to keep the reference leg temperature approximately halfway between saturation and ambient temperature, according to David A. Kalix, PE, who works for Yarway and covered the topic in his 1995 ISA paper, “Density Error and Its Correction in Boiler Drum Level Indication.”

A reference leg temperature measurement can be retrofitted into an existing installation like that shown in Figure 1 by adding a thermocouple that is in contact with the tubing skin of the reference leg. To carry out this retrofit, however, this thermocouple would need to be attached at an elevation that is midway between the top and bottom connections of the steam drum. If the reference leg is heat-traced for freeze protection purposes, it would be important to place the thermocouple on the opposite side of the reference leg tubing from the heat tracing. This thermocouple and the reference leg tubing adjacent to it should then be insulated and weatherproofed. The thermocouple can then be brought into the control system and incorporated into the drum level measurement pressure compensation algorithm.

A reference leg temperature measurement can also be retrofitted to an existing temperature-equalizing column installation (see Figure 4 and the right side of Figure 2). In this case, the thermocouple would be attached to the column skin midway between the top and bottom column connections, and insulation would be placed over the top of it. In the case of a Yarway temperature-compensated constant head chamber such as the one shown on the left side of Figure 2, a thermocouple must be placed in direct contact with the reference leg (also called the constant head pipe) that is underneath the stainless steel jacket.

This exact situation occurred last year during a scheduled outage at two of our steam plants. In those two cases, plant managers decided to add reference leg thermocouple measurements and to bring those signals into the control system. The data collected since these two units were brought back online show that when the units are operating near their 1,900 psig normal operating pressure, the three Republic columns that are in place between these two units (right side of Figure 2) are within 15F of the saturation temperature. This confirms the assumption that the Republic columns will be near the saturation temperature when they are properly insulated. (Note that the Figure 2 pictures were taken before the thermocouples were added and before the Republic column was re-insulated.)

The data also show that when the unit with the single Yarway column is operating near its 1,900 psig normal operating pressure, the reference leg associated with that column (left side of Figure 2) is about 126F below the saturation temperature. This shows that the assumption of the Yarway being halfway between saturation and ambient is not always correct, because our measurements show the reference leg in this column to be operating three-quarters of the way between ambient and saturation.

Recommendations for Dealing with Older Columns Still in Operation

The type of temperature-equalizing columns plant personnel encounter at their facilities determine what course of action should be taken in order to ensure optimum steam drum level measurements. Here are our recommendations:

- Because temperature-equalizing column designs similar to the Bailey and Republic columns are prone to flashing, it is recommended that these and similar columns be removed from service and replaced with an arrangement similar to that depicted in Figure 1, minus the reservoir if the transmitter has negligible displacement.

- Because temperature-equalizing column designs similar to the Yarway columns have a less-predictable reference leg temperature, they should either be retrofitted with a reference leg temperature measurement or be removed from service and replaced with an arrangement similar to that in Figure 1.

- For arrangements similar to Figure 1, the assumed reference leg temperature, which is usually 100F, should be investigated and verified. If that assumption is not reasonable, then the assumed temperature should be modified. When the reference leg is outdoors or if that leg is indoors but the ambient temperature is expected to vary widely, consideration should be given to measuring the reference leg temperature and bringing that temperature into the compensation calculation in the plant controls.

This article is based on a paper presented by the author at the 15th Annual POWID/EPRI Controls and Instrumentation Symposium.

— Dale P. Evely, PE (dpevely@ southernco.com) is principal engineer, I&C Technical Support, at Southern Co. in Birmingham, Alabama.