Eddy current testing is a well-established method of nondestructive testing that is used to examine nonferrous/nonmagnetic materials such as condenser and heat exchanger tubes in power generation plants. Eddy current testing reveals discontinuities in tubing, provides plant engineers with an accurate assessment of a unit’s condition, and is a tool for predicting the remaining useful life of the tubes. Along with condenser and heat exchanger tube cleaning and leak detection applications, many power generation plants with aging units include eddy current testing in plant maintenance programs in an overall effort to maximize the efficient life of their units.

The power generation industry is but one of many sectors that benefit from eddy current and other nondestructive testing applications. Some common applications of eddy current testing outside of power generation are inspections of aircraft sections, automotive components, and machined parts to search for surface and subsurface cracks and corrosion.

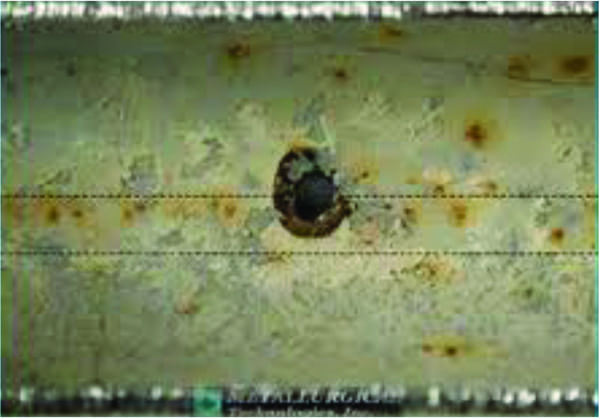

Eddy current testing can be a powerful tool in a power plant’s maintenance program. Every year in the U.S. there are an estimated 7,000 plant outages attributed to tube failures, and such outages are expensive and disruptive. Regular tube inspections can detect failing tubes (Figure 1) before they become catastrophic, and it can minimize the losses associated with plant unavailability. Early detection of potential failure mechanisms enables plants to develop operating strategies, perform preventive maintenance, and more accurately budget for equipment repair and replacement, because the remaining useful life of the unit is better understood.

1. Finding problems before they find you. The pitting defect visible in this image was detected using eddy current testing. Courtesy: Conco Services Corp.

Obtaining Accurate Eddy Current Test Results

There are many variables that influence the capabilities of an eddy current test. In any given inspection, the probe that is used will affect resolution, and the data that is collected will depend on the characteristics of the equipment being tested.

While features of condenser or heat exchanger tubing, like permeability and conductivity, are beyond the control of the eddy current technician, appropriate choices about the coil size, coil type, and the test frequencies that will be used can ensure that the most conclusive data is collected. Other factors that influence the eddy current inspection process are the calibration standard, fill factor, tube cleanliness, and probe speed. As is often the case, successful and accurate analysis is often based on the expertise of the analyst.

Single Frequency Versus Multiple Frequencies. With eddy current testing, more is better—frequencies, that is. The American Society of Mechanical Engineers (ASME) code on eddy current testing requires only the use of the prime frequency needed to obtain a desired response, but it allows for the use of additional frequencies. The use of multiple testing frequencies is an essential element in testing because it allows for complete penetration of the tube wall from various perspectives.

Multiple frequencies are required to gain accurate and detailed data on suspected defects, and to maximize the ability of the technology to better detect, measure, and confirm flaws in all areas of a tube wall. Subsequent frequencies each have their strengths for detection and allow for signal mixing to eliminate unwanted interference like tube support plate signals. Today’s eddy current instruments have the capacity to employ eight or more frequencies, but, more commonly, analysts are utilizing a minimum of four.

Good Preparation: The Importance of Clean Tubes. For an accurate and successful eddy current inspection of your condenser and heat exchanger tubes, effective tube cleaning must first be performed. Fill factor is the volume at which the eddy current probe occupies the inner diameter of the tube being tested, and it is an important variable in the quality of an eddy current inspection. Fill factor is reduced when tubes are not clean.

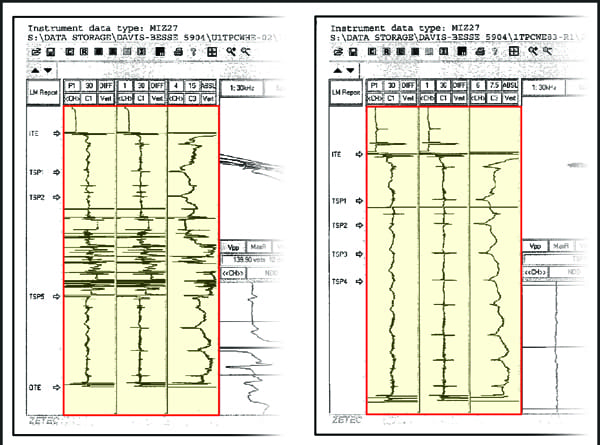

For an inspection to have high accuracy and repeatability, the eddy current probe must be able to achieve a fill factor of 85% or higher, with the probe occupying as much of the diameter of the tube as possible. High fill factor provides better magnetic coupling with the tube and superior data acquisition. Fill factor that is too low will reduce the quality of the data and increase the likelihood of false signals and masked defects. Along with fill factor, dirty tubes increase the signal-to-noise ratio that is a vital component of the eddy current inspection (Figure 2).

2. Preparing for success. Clean tubes are essential for accurate eddy current testing. The graph on the left displays data from a dirty tube, which shows a poor signal-to-noise ratio, while the graph on the right was obtained from a clean tube, which exhibits a good signal-to-noise ratio. Courtesy: Conco Services Corp.

Whatever cleaning method is utilized, condenser and heat exchanger tubes should be cleaned as close to the tube surface as possible. The silver lining for the plant is that the return on investment associated with tube cleaning is significant. Tube fouling and corrosion can cause major loss of heat transfer and, if left unattended, even tube failure.

In preparation for eddy current testing, a common practice is for plants to contract with a tube-cleaning specialist. Tube cleaners are inserted into the tubesheet in the inlet waterbox. Then, pressurized water is used to shoot the cleaners through the tubes. Debris and obstructions are flushed from the tubes, making them ready for eddy current testing. Typically, metal tube cleaners can be used eight to twelve times before they become ineffective, so an investment in mechanical cleaners will usually be recouped quickly.

The Eddy Current Process at a Glance. After the condenser or heat exchanger tubes have been cleaned and are prepared for testing, a certified nondestructive testing technician chooses one of a variety of probes that is appropriate for the testing application. Once inserted into the tube, an alternating current flows through a wire coil in the eddy current probe and it generates an oscillating electromagnetic field. As the probe and its magnetic field are brought close to the conductive material of the tube, the circular flow of electrons, also known as the eddy current, begins to move through the tube like water swirling through a pipe.

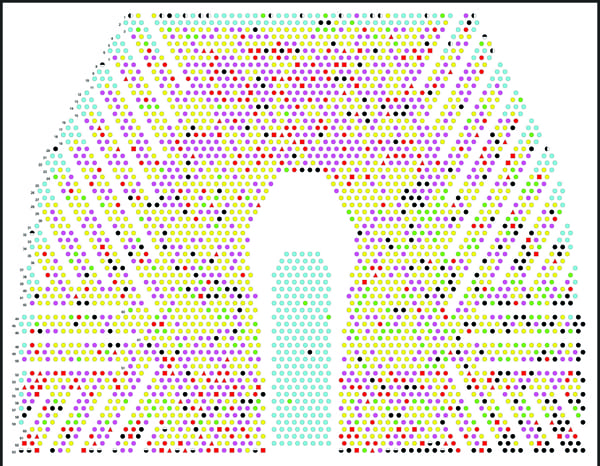

The interaction of the eddy currents flowing through the tube metal and the magnetic field of the coil will provide the valuable data points that tell the story of the tube’s condition. Changes or variations in the eddy currents are caused by defects in the tube wall, such as near-surface cracks and inconsistencies in metal thickness. The eddy current instrument records the pattern of variations and they are analyzed to draw conclusions about the condition of the tubes. Over time, results can be compared and any trends or progression in the defects can be observed, which will guide maintenance decisions (Figure 3).

3. Graphic results. The condenser tubesheet map shown here is color coded with eddy current testing results. Courtesy: Conco Services Corp.

Remote Field Testing

While both eddy current and remote field testing (RFT) are nondestructive examination methods that rely on the science of electromagnetic induction, they are very different in operation and application. Eddy current testing relies on direct coupling between the inspection coil and the test material. It is effective with nonferrous tubing, such as copper, brass, and titanium. RFT is a method used to inspect ferrous tubes, such as carbon steel and ferritic stainless steel. It was developed to overcome the permeability effects in ferromagnetic tubing.

The RFT inspection process uses slower probe speeds, and it is less sensitive to local defects than conventional eddy current testing. Yet, it still provides valuable information on tube condition. Higher fill factors are not as critical in RFT as in eddy current testing, with 60% to 70% fill factor being commonplace. Although RFT can detect both internal and external defects, it cannot distinguish between them.

Tube Plugging

If the results of eddy current or RFT inspections indicate that a tube is badly compromised, it should be plugged. The generally accepted tube plugging threshold for throughwall penetration is >60%, but it can vary given risk tolerance. Choosing to plug tubes proactively is preferred by most over having to respond to a tube leak or a catastrophic tube failure. In either scenario, the plant will need to have tube plugs in inventory.

A good rule of thumb is to maintain an inventory of tube plugs equal to two percent of your tube quantity. For example, if a plant’s condenser has 10,000 tubes, it is recommended that 200 tube plugs be kept in inventory. When selecting tube plugs, purchasing personnel will need accurate information on the size of the tube to be plugged, the tube material, and whether or not the tube plug will be temporary or permanent.

Preventing tube fouling and failures in your plant is a worthy objective. Preventive maintenance could be the path of least resistance toward achieving that goal. Equipment repair and replacement costs the industry hundreds of millions of dollars annually, but with a more proactive commitment to ongoing maintenance, costly unplanned outages and equipment replacement can be avoided. Eddy current testing is an impressive tool that can help in this effort.

—Beth Foley-Saxon is a staff writer in the Marketing department at Conco Services Corp.

https://www.powermag.com/eddy-current-tube-inspections-efficiently-find-defects/?pagenum=1