Many informative articles have been published about options for treating flue gas desulfurization wastewater, but new technologies are rapidly changing the treatment possibilities. This article reviews key economic considerations and introduces an innovative treatment solution that lowers costs and the amount of waste generated.

Many informative articles have been published about options for treating flue gas desulfurization wastewater, but new technologies are rapidly changing the treatment possibilities. This article reviews key economic considerations and introduces an innovative treatment solution that lowers costs and the amount of waste generated.

Flue gas desulfurization (FGD) wastewater varies widely depending on the source facility, the type of coal burned, and the FGD system employed. However, almost all FGD wastewater is highly scaling. To achieve compliance with treatment regulations, operators must successfully manage scaling and they need to understand the different types of scaling. This is especially important for zero liquid discharge (ZLD) applications, where scaling is of great concern.

FGD wastewater contains the following types of scalants:

■ Low-solubility metals, such as iron, nickel, cobalt, and aluminum. These can create scaling compounds, but raising pH via caustic or lime addition can readily precipitate them.

■ Low-solubility anions, such as fluoride, phosphate, and sulfate. These can combine with calcium to create scale. They cannot be readily removed to reliable levels through precipitation, therefore further management is required.

■ Divalent cations responsible for high hardness, primarily calcium and magnesium, as well as barium and strontium. Elevating pH will precipitate magnesium, but it has little effect on calcium, barium, or strontium, unless carbonate is present, which is uncommon in FGD wastewater. That is why conventional treatment processes add carbonates in the form of expensive soda ash (sodium bicarbonate).

Conventional Treatment Processes

Although FGD wastewater chemistry varies between facilities, there are common treatment systems employed.

Lime (Calcium Hydroxide) Softening. This system removes magnesium hardness and heavy metals. Some calcium is removed, but only calcium that is “associated” with carbonate.

Soda Ash (Sodium Carbonate) Softening. This system removes calcium hardness. Soda ash is one of the most expensive processes for FGD wastewater treatment. Costs are often about $4 per cubic meter (m3) inlet, accounting for more than 20% of the total cost of ownership (capital plus operating cost) of the treatment. Some waters are higher in magnesium and lower in calcium, so costs vary.

Ion Exchange. This system employs resins to absorb calcium, reducing calcium levels to less than 50 milligrams per liter (mg/L). However, the resins are not effective in high salinity FGD water and must be regenerated with acid, resulting in high operating costs and acidic chemical waste that requires disposal.

Reverse Osmosis (RO). This is the most dominant and widely practiced desalination technology for removal of total dissolved solids (TDS). RO is low cost, but requires notable chemical pretreatment to be reliable on FGD wastewater. On scaling ion chemistry, RO is susceptible to fouling and does not concentrate well past 60,000 mg/L, that is, about 50% to 65% recovery on FGD water. This results in low recoveries and high brine volumes (or requires very frequent chemical cleaning). Advancements in modified RO units, such as New Logic Research Inc.’s vibratory shear enhanced processing (VSEP) fouling-resistant membrane filtration product line, reduce the need for chemical pretreatment and boost recovery, but operators need to plan for chemical cleaning to maintain operations. Any RO unit can be hybridized with the innovative treatment system presented in this article, but a VSEP unit will add a further boost to recovery.

Thermal Brine Management (Evaporator, Crystallizer, SaltMaker). Evaporators concentrate the final brine waste and crystallizers produce solids. These systems are required for brine management and ZLD—and are the most expensive process equipment in the treatment train in terms of both capital and energy cost. The required capacity and energy used by these systems can be reduced if the recovery of upstream membrane systems is increased. Membrane systems are often one-fifth to one-tenth the cost per unit volume processed; therefore, it makes sense to maximize their recovery.

Reducing Treatment Costs

In smaller power plants and lower flow FGD systems, such as less than 50,000 gallons per day (189 m3/day), it may not be economical to include an upstream membrane system to reduce volume prior to the evaporation stage. However, in larger flow systems, an upstream membrane system offers economic advantages.

Nevertheless, both conventional membrane and evaporation systems require expensive chemical softening to ensure reliability. There are cases of past FGD systems that did not employ soda ash, only to later require retrofitting at much expense and disruption. Designers should therefore plan for calcium and other scalant management at the start of their project, either through inclusion of a soda ash softening step or consideration of the technology presented herein.

Designers should also plan for final disposal of the residual waste produced from the treatment process, because the waste can be considered hazardous in some jurisdictions. Hazardous waste results in high disposal costs as conventional landfills cannot be used. Disposal cost and risk can be reduced by adding fewer treatment chemicals overall, as well as recovering by-products of value from the residual waste for reuse, such as sodium sulfate.

Plant designers can most effectively lower treatment costs by focusing on the biggest cost levers. Some worthy objectives include:

■ Reducing soda ash softening while maintaining reliability in process equipment

■ Increasing membrane system recovery to reduce the capacity of downstream brine management systems

■ Reducing the overall mass of residual waste and the mass of hazardous waste

An Innovative High-Recovery FGD Wastewater Treatment System

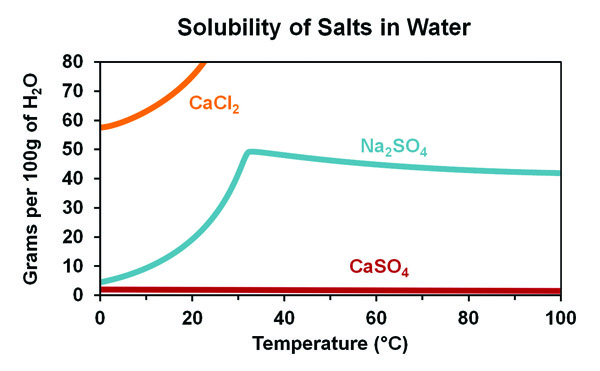

A solution that accomplishes the above three goals was developed by Saltworks Technologies. It builds on the past work of Toshikatsu Hamano and Thomas Davis. In 1993, Hamano developed a desalination process with two electrodialysis stages that permanently changed low-solubility calcium sulfate into highly soluble calcium chloride and sodium sulfate. Solubility of these ion pairs is shown in Figure 1 (low solubility means greater scaling risk). Davis worked on a similar process in 2008, when he developed an electrodialysis metathesis (EDM) process for feed waters comprised solely of calcium sulfate. Saltworks further innovated on top of Davis’ excellent work and has an exclusive license to Davis’ patents.

1. Solubility of salts in water. This graph shows the solubility of calcium sulfate (CaSO4), calcium chloride (CaCl2), and sodium sulfate (Na2SO4). Less soluble compounds have a greater risk of scaling. Courtesy: Saltworks Technologies

Saltworks’ system, trade named Salt Splitter, expands on this work with several proprietary innovations—monovalent selective ion exchange membranes, process, and controls—that enable an industrially applicable treatment plant. Salt Splitter is built around the two most common desalination technologies: electrodialysis and RO.

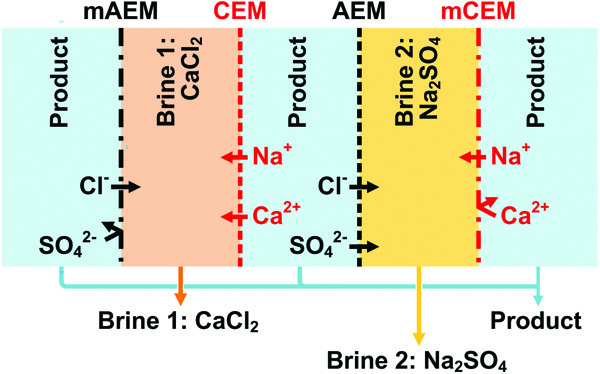

The advanced salt splitting electrodialysis unit acts as a turbocharger for the RO. It removes scaling limits by permanently changing water chemistry. Divalent scaling low-solubility ion pairs, such as calcium sulfate, are “split” into nonscaling high-solubility ion pairs, such as sodium sulfate and calcium chloride.

The RO unit operates on an electrochemically-softened feed, at a greater reliability level and lower pressure than conventionally possible. The combined Salt Splitter-RO hybrid produces two highly soluble output brines with a combined average brine concentration of about 210,000 mg/L TDS. These can be sent to separate downstream processing stages for volume reduction or solidification. A simplified electrodialysis stack arrangement diagram, showing how the ions are selectively transferred into separate brine compartments to produce nonscaling Na2SO4 and CaCl2, is shown in Figure 2.

2. Stacked for success. The Salt Splitter stack arrangement produces calcium chloride (CaCl2) and sodium sulfate (Na2SO4) from calcium sulfate (CaSO4) present in FGD wastewater. Courtesy: Saltworks Technologies

The Salt Splitter-RO system provides the following benefits:

■ Recovery of the membrane system is 85% to 95% versus 50% to 65% for RO alone, resulting in a two-thirds reduction in brine volume relative to that of chemically softened RO, while eliminating the need for expensive soda ash softening

Improved RO reliability and reduced operating costs from lower pressure requirements

■ The nonscaling, lower volume brines reduce the need for chemical softening of the evaporator inlet and allow downsizing of brine management assets

■ Less residual waste mass is produced because soda ash addition is eliminated and because useful by-products, such as sodium sulfate, can be recovered from the waste.

In sum, Salt Splitter-RO is a membrane system that can change the cost equation for FGD wastewater treatment. The Salt Splitter stack does consume electrical power, which is accounted for in the economic analysis that follows. On feed water with an imbalance of monovalent ions to scaling divalents, such as waters supersaturated in calcium sulfate, monovalent ions in the form of sodium chloride must be added. However, sodium chloride (NaCl) is low cost, widely available, and safe to handle. NaCl costs are also accounted for in the economic analysis that follows.

RO permeate may contain residual boron, which is generally not a challenge for reuse regulations, if the water is used on-site for cooling tower make up. If off-site surface discharge is desired, depending on the FGD wastewater, a second stage RO operating at elevated pH and around 98% recovery may be required to polish boron, with the second stage RO brine sent to the evaporation system.

Splitting calcium sulfate into separate sodium sulfate and calcium chloride streams also benefits solidification in downstream evaporation and crystallization systems, and provides greater flexibility in managing residuals. A series of customizable options are available to plant designers. They include:

■ Sodium sulfate and calcium chloride brines can be recombined to produce gypsum (CaSO4(s)), widely used in building materials. The resulting brine reject will be rich in sodium chloride and can be further concentrated. However, many will find the next two options to be better alternatives.

■ Sodium sulfate brine can be separately concentrated and readily precipitated due to its steep solubility curve with temperature. In fact, some systems have produced as high as 90% pure sodium sulfate. Sodium sulfate of this purity can be used in a wide range of industries including detergent manufacturing, pulp and paper, and glass making.

■ Calcium chloride brine can be separately concentrated and used industrially as a “heavy brine” for oil and gas well completions or for hardening concrete, roads, and bricks. Calcium chloride rich brines can be readily solidified and encapsulated by mixing with fly ash and cement, offering the advantage of reducing long-term leaching risks and enabling safe disposal of a solid waste.

Regardless of the option selected, designers can use Salt Splitter’s elegant chemistry and ion separation to design and adjust processes to meet specific site needs.

Putting Theory into Practice

A fully automated Salt Splitter-RO pilot plant (see opening photo) was operated on FGD wastewater from a coal-fired power plant. The objectives were to confirm treated discharge water quality; confirm membrane system recovery, reliability, and chemical and energy consumption; and to develop the economics for a full-scale system, including a downstream evaporator-crystallizer.

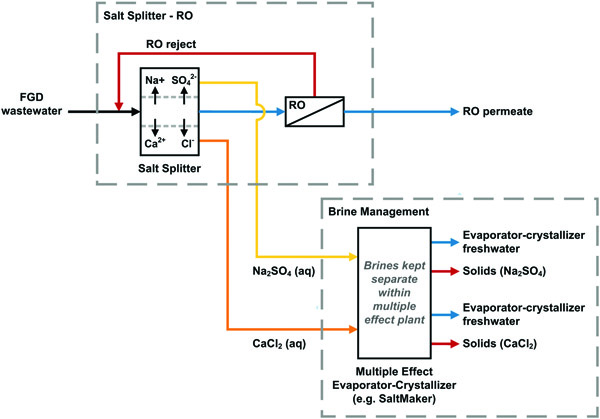

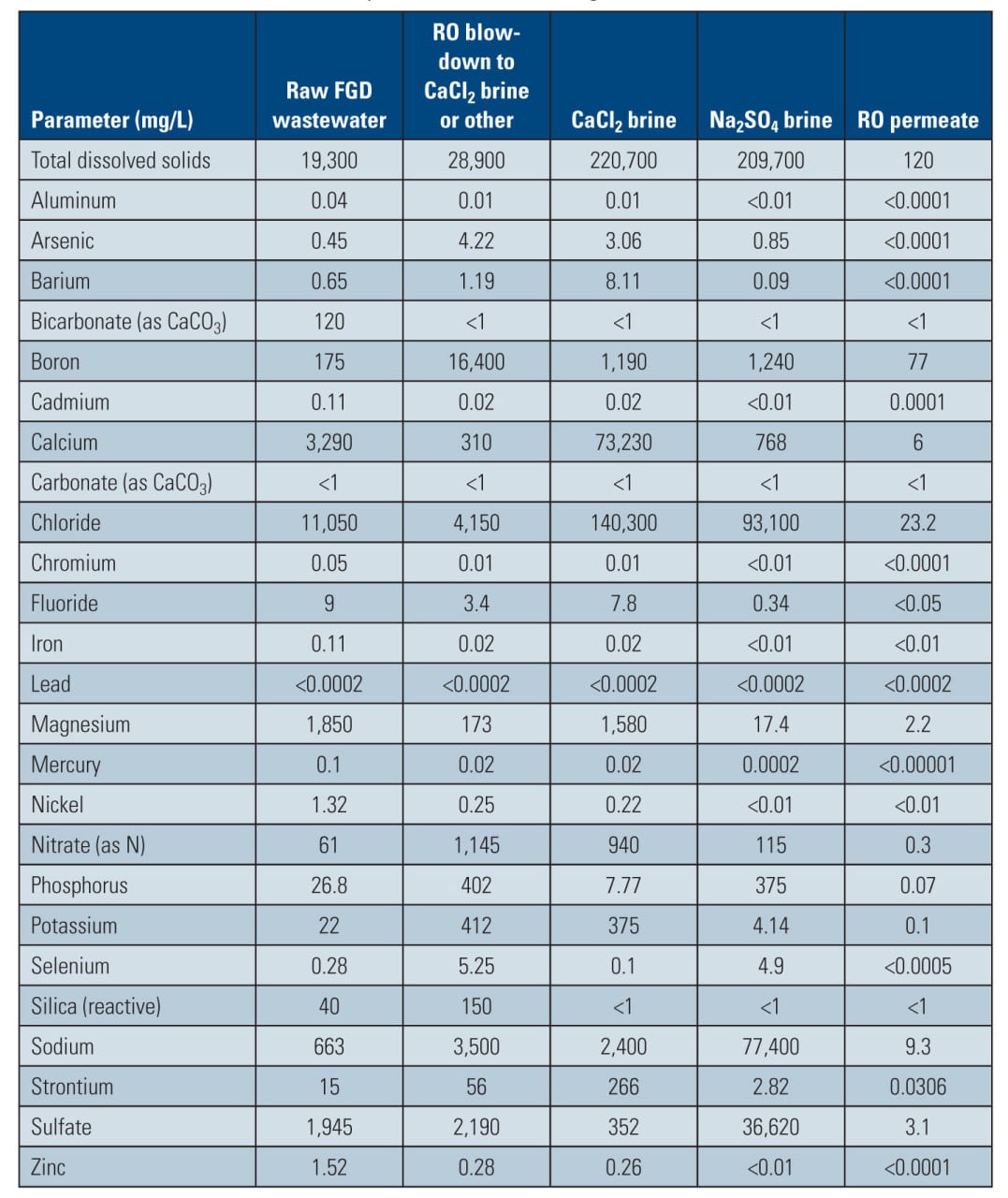

The treatment process is shown schematically in Figure 3. Pretreatment for the RO unit was required, such as multimedia filtration or ultrafiltration. Detailed analytics for all streams are shown in Table 1. A proprietary precipitation step was employed to reduce transition metals and silica load, while producing a solid sludge for solidification. This precipitation step reduces transition metals and silica mass in the respective brines.

3. The Salt Splitter-RO hybrid. Flue gas desulfurization (FGD) wastewater is processed first in the electrodialysis unit, which produces separate sodium sulfate (Na2SO4) and calcium chloride (CaCl2) streams, and then through reverse osmosis (RO). Courtesy: Saltworks Technologies

Table 1. Salt Splitter-RO system analytics. The parameters shown here are from an actual field test. An optional upstream precipitation step was employed in this example. Therefore, the reject brine has less silica and transition metal load, and excess calcium mass relative to the raw water. Courtesy: Saltworks Technologies

The Salt Splitter-RO system successfully treated the FGD wastewater to meet both Chinese and U.S. discharge regulations. The pilot plant operated continuously for 90 days. Freshwater recovery of 90% was achieved from the membrane system, with no soda ash softening. In comparison, chemically softened RO system projections showed a recovery of approximately 70%.

Put another way, the Salt Splitter-RO system produced one-third of the brine reject volume—or 67% less brine—requiring a 67% smaller evaporator system. Salt Splitter-RO generated nonscaling, high-concentration, low-volume brines. The RO unit produced an extremely low-volume blowdown stream (about 0.27% of inlet flow), which was high in silica, boron, and any organics not removed by pretreatment. The RO blowdown was sent and mixed with the CaCl2brine or it could be separately concentrated, if CaCl2 reuse had been preferred. Most importantly, two nonscaling brines were produced in excess of 200,000 mg/L, which is brine concentration territory normally reserved for evaporators.

Salt Splitter’s highly selective monovalent ion exchange membranes and RO unit performed reliably with no performance or membrane scaling/degradation. A small-scale evaporator-crystallizer was operated to further concentrate the low-volume brines and generate sodium sulfate with a purity of 85% to 90%, which is suitable for industrial reuse. These results are consistent with other Salt Splitter-RO trials ranging from a U.S.-based coal-fired power plant to a Canadian-based coalmine. All wastewater had one common theme: It was saturated in CaSO4, which previously limited recoveries and required extensive chemical pretreatment.

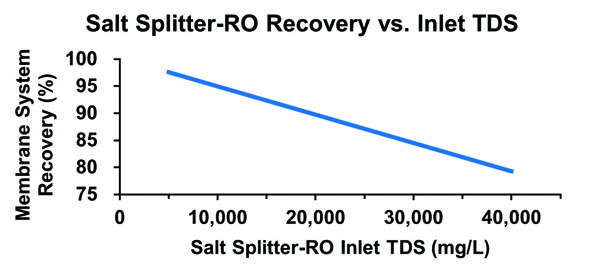

The FGD wastewater tested had moderate salinity compared to some sites. The tested wastewater had a TDS of about 19,000 mg/L, whereas other sites can be as low as 5,000 mg/L to more than 30,000 mg/L. FGD wastewater of all salinities is applicable to the Salt Splitter-RO process; however, recovery changes with inlet TDS.

For example, RO systems with a 1,000-psi operating pressure are often osmotic pressure limited to a practical brine concentration of about 85,000 mg/L; however, scaling ions can prevent reaching this limit. Electrodialysis is not limited by osmotic pressure, as it is not an osmotic pressure driven process. Electrodialysis can also be scaling ion limited, but once those limits are removed, electrodialysis is limited by the osmosis of the water being “sucked” across ion exchange membranes due to brine concentration gradients.

If scaling limits are removed, such as in the Salt Splitter-RO process, the system’s brine concentration is limited by osmosis of water from the treatment circuit into the concentrated brines. Results from three trials reveal that the upper brine concentration limit of the Salt Splitter-RO process is about 210,000 mg/L TDS. Previously, no membrane system could achieve such high brine concentrations, with the exception of forward osmosis including a thermal regeneration step and soda ash softening—the Salt Splitter-RO process requires neither.

Due to the upper limit of brine concentration being about 210,000 mg/L TDS, higher salinity inputs will result in lower recoveries. For instance, if the inlet water were already at 210,000 mg/L TDS, the system would not be able to recover any water. Likewise, for waters with lower inlet TDS, system recoveries would increase. The relationship between system recovery and inlet TDS is depicted in Figure 4. Readers can roughly estimate membrane system recovery for their system by dividing their wastewater’s raw TDS in mg/L by 210,000 and subtracting the value from 1.

4. Linear recovery. Raw wastewater with high salinity will have a lower recovery rate than low-salinity wastewater. Courtesy: Saltworks Technologies

Comparison and Economics

The first step in a typical conventional treatment train for highly scaling wastewaters, such as FGD wastewater, is chemical pretreatment including lime and soda ash softening to reduce the scaling potential of the water. An RO unit is then used for initial desalination. The RO brine reject is then directed to an evaporator for volume reduction, followed by a crystallizer in ZLD systems. Lime and soda ash softening may also be required upstream of the evaporator to manage scaling, depending on the equipment being used.

A comparison of the costs associated with the conventional treatment train and the Salt Splitter-RO-crystallizer treatment train was completed (see the online version of this article to view a spreadsheet containing the detailed analysis). The design basis for comparison assumed 200-gallon-per-minute (1,090 m3/day) inlet capacities, with the FGD wastewater chemistry shown in Table 1. It also assumed that true ZLD was required, meaning only solids and treated water would be allowed to leave the plant.

Capital costs were based on U.S. market prices for chemical softeners, industrial reverse osmosis, and evaporator-crystallizers. Only process equipment costs were accounted for in both options. Building and installation costs were not accounted for and assumed to be the same for both options. Capital costs were amortized over 10 years at an 8% discount rate. Plant availability was assumed to be 95%, allowing 5% for maintenance and downtime. Power costs were assumed to be $0.065/kWh and thermal energy costs were estimated to be $3/MMBtu, although low-pressure steam (

The Salt Splitter option assumed that sodium sulfate was produced and provided to industry at no cost or revenue addition. The calcium chloride brine was concentrated to about 80% total solids by mass in an evaporative-crystallizer and then solidified with the addition of fly ash and cement. Similarly, for the conventional treatment train, the crystallizer discharge was concentrated to about 80% total solids by mass and then solidified. Solidification agent and tipping fee costs for both options were not included due to operators having very different methods.

The Salt Splitter-RO system resulted in capital cost savings of 25% compared to the conventional treatment train, saving the operator $2.2 million in capital cost on the process equipment for a 200-gallon-per-minute plant. In addition, by eliminating soda ash softening, the Salt Splitter-RO option resulted in operating cost savings of 37%, saving the operator roughly $1 million per year. Ultimately, the Salt Splitter-RO system resulted in a total cost of ownership savings of 45%. In addition, the Salt Splitter option resulted in a lower regulatory risk profile due to reduced risk of hazardous waste generation, and lower transportation and safety risk due to reduced chemical (soda ash) usage. However, all projects are unique, so economic results may vary.

The Salt Splitter-RO system required addition of sodium chloride in this particular case due to insufficient monovalent ions in the raw solution. That added $14,000 per year in operating cost but removed the cost of adding soda ash, saving $1.2 million per year. Salt Splitter also consumes electrical power to move ions in the process, but less than an evaporator, which achieves similar brine concentration. Total system electrical power savings were calculated to be 38%.

Final solids mass was reduced by 30% due to eliminating soda ash addition and the opportunity to beneficially reuse solid sodium sulfate produced. Solidification agent costs were not included, such as fly ash or cement for both scenarios. As such, savings from the calcium chloride brine benefiting solidification were not accounted for, but will further benefit Salt Splitter-RO economics. Future work will focus on increasing the beneficial reuse of the produced solids and lowering solidification costs.

A Viable Treatment Option Worth Considering

Changing regulations are driving both innovation and the uptake of FGD wastewater treatment solutions. Treatment approaches vary widely depending on the facility and its particular water chemistry, flow rate, and discharge regulations. However, to optimize treatment economics, there are steps an operator or plant designer can take that are consistent across all facilities. They are:

■ Eliminate soda ash softening

■ Increase membrane system recovery to reduce the size of thermal evaporation technologies

■ Minimize overall residual waste and minimize the amount of hazardous waste

The case study and economic comparison presented in this article demonstrates the Salt Splitter-RO system’s ability to achieve these objectives. The system also provides operators and plant designers with flexible options for managing residual waste, including the ability to beneficially turn waste into reusable by-products. The Salt Splitter-RO system has been utilized in other highly scaling industry applications, such as mine discharge water treatment, and it can be applied anywhere reverse osmosis recovery is limited by scaling ions. ■

—Mitchell Frank is science and knowledge manager, Ben Sparrow is chief engineer, Joshua Zoshiis a senior technical leader, and Megan Low is process engineering manager for Saltworks Technologies Inc.

https://www.powermag.com/lowering-cost-waste-flue-gas-desulfurization-wastewater-treatment/