Varnish buildup in oil systems and components can degrade performance and cause erratic valve operation. Some experts have conducted research and formulated new lubricants that could help solve those problems. One such oil proved highly successful during a five-year run at a gas turbine power plant. By eliminating the need for oil changes and valve maintenance at the site during the trial period, the oil even saved money compared to previously used formulations.

The formation of varnish by turbine oils is not a new phenomenon. However, it has become an intense topic of discussion over the last several years because of the resulting downtime, decrease in reliability, and loss of productivity it causes in the power industry. There are a few significant factors that contribute to this issue.

Dynamics Behind Varnish Formation

Through intense focus on asset reliability and operational efficiency, end users have begun to push limits and increase the performance of their power units. The same focus by original equipment manufacturers (OEMs) has led to higher performing equipment. On the lubricants side, recent turbine oils that were made from American Petroleum Institute (API) Group I base oils and derived from a solvent-refining process also posed challenges.

Although these lubricants met most of the performance specifications set by the OEM, they were known to oxidize and leave insoluble varnish residues under more severe applications, such as in peaking units. The cycles of hotter and cooler oil circulating in systems also encourages varnish deposits, which explains why peaking units are more affected. Due to the large size of the reservoirs and end users’ ability to postpone total fluid replacement through partial oil replacement, these API Group I-based turbine oils were often overextended, as they were left in operation longer than they probably should have been (Figure 1). The conventional oxidation tests often did not detect alarming conditions in oil samples, even though the equipment might have shown signs of advanced oil degradation.

Thanks to improvements in oil analysis and the development of detection techniques to quantify the concentration of molecules that could possibly turn into varnish (varnish precursors), it is now better understood how much difference there is in turbine oil degradation based on quality, purity, and formulation, including the foundation of it all—the base-oil group. This change in detection has been helpful for the industry; however, understanding the cause of formation is only one piece of the puzzle. Managing it is still a challenge many operations are struggling to overcome.

Varnish Management

Traditionally, operators and maintenance managers have dealt with varnish reactively. When varnish is detected, they take steps to remove it. Detection methods usually involved inspecting components, such as the oil filters, the last chance filters, and metal coupons in the oil reservoir, while standard removal techniques included processes such as chemical filtration or electrostatic purification. This approach made sense when varnish was less of a challenge.

However, since fluid and operational demands have changed, following standard varnish management practices has become less effective for turbine operators and maintenance managers. Even with greater diligence, using the old methods means hard-to-detect varnish is still causing inefficiencies and unplanned turbine outages.

Therefore, industry best practices have evolved. Many leading plants are leaning towards proactive varnish prevention rather than reactive management of heavy varnish buildup. This includes utilizing turbine fluids with different properties—ones that can handle higher temperatures, endure the cyclic demands of peaking operations, and account for issues with solubility.

In order to withstand the stress, gas turbine lubricants need greater oxidation resistance and higher thermal stability. Great foaming resistance and better air release are also essential for the next generation of solutions. Finally, these products must be maintained to a cleaner standard, with more stringent filtration.

Real-World Testing

When a lubricant is unable to do its fundamental job, the result can be costly. Converting to the right turbine fluid is an important decision that can only be made after reviewing critical product specifications, such as relevant field data supporting the claims made on a technical data sheet.

Trialed in the field at a large U.S.-based power producer from May 2010 to April 2015 (and still running), the TURBOFLO LV prototype was installed in two GE Frame 7FA units used primarily in peaking service. During the entire 5-year trial period, there was no evidence of varnish formation, but there is more to the story.

During the test period, each of the units averaged approximately 23 starts per month and accumulated more than 9,000 operating hours. A fixture containing several metal coupons in the main lubricant reservoir of each unit monitored the accumulation of varnish deposits. Oil samples were taken at regular intervals from both demonstration units. Used oil analysis ensured the oil was suitable for continued use while more sophisticated testing was performed to evaluate the TURBOFLO LV prototype in the areas of oxidation and varnish formation.

The units with the prototype fluid exhibited superior performance in several distinct areas.

Extended Valve Life. Prior to the trial, the site reported replacing valves every six months to ensure reliable operations. During the five-year trial, no valves were replaced and neither unit experienced any varnish-related trips.

Enhanced Fluid Resistance to Varnish Deposits. The quantitative spectrophotometric analysis (QSA) test measures the concentration of varnish precursors in oil. A rating of 50 or more indicates that the fluid should be replaced before varnish-related complications affect reliability. In the trial period of 9,000 operating hours over 1,200 days, the TURBOFLO LV prototype exhibited very low QSA ratings (<10).

Last Chance Filter (LCF) Life Extension. LCFs were taken from one of the test units as well as from a different Frame 7FA turbine unit in similar service that used conventional turbine oil. The LCF from the turbine operating on the TURBOFLO LV prototype was clean, bright, and free of deposits, whereas the LCF from the other unit had a sticky varnish-like coating.

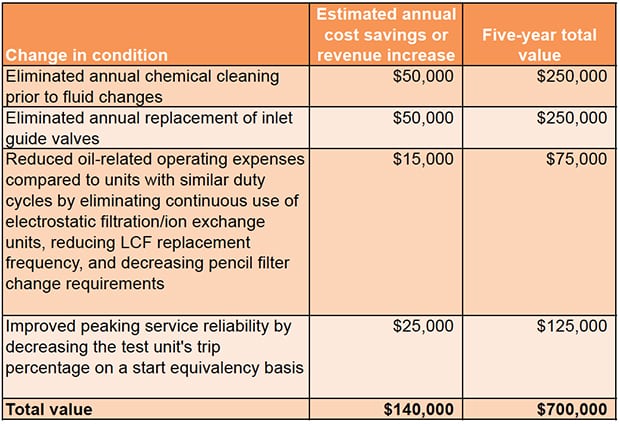

Cost Savings. Besides the oil staying in excellent condition, results from the field trial proved that the TURBOFLO LV prototype delivered cost savings of approximately $700,000 per unit over the five-year period (or nearly $140,000 per unit per year). The benefits calculated are shown in Table 1.

|

Table 1. Improved financial performance. Benefits of changing to a higher-grade lubricant are shown here for a GE Frame 7FA test unit. Source: Petro-Canada America Lubricants Inc. |

Lab Trials

In addition to field trials, industry-standard tests demonstrate how TURBOFLO LV 32 performed against modern turbine oils. The independent benchmark study showcased the following results:

- In the membrane patch colorimetry varnish test (ASTM D7843), a key indicator of varnish potential in lubricants, after eight weeks in an oven at 80C (176F), the sample yielded a very low rating of 1.3.

- In the air release test (ASTM D3427), a leading indicator of oxidation resistance obtained by measuring the oil’s ability to rapidly dissipate air, TURBOFLO LV 32 measured 1.2 minutes at 50C—well below the four- to seven-minute maximum listed in turbine OEM specifications.

- In the pressure differential scanning calorimetry test (ASTM D6186), a technique for evaluating the oxidation resistance of a lubricant obtained by subjecting specimens to 500-psig oxygen at 180C (356F), TURBOFLO LV 32 outlasted all of the lubricants benchmarked, which proves its excellent oxidation stability.

- In the turbine oil stability test (ASTM D943), TURBOFLO LV 32 exceeded the maximum test limit of 10,000 hours. This result is well above the typical 2,000- to 5,000-hour requirement in OEM specifications. This once again demonstrates TURBOFLO LV’s exceptional resistance to oil breakdown in the presence of moisture and air at high temperatures. For operators, it means TURBOFLO LV 32 lowers operating costs by extending intervals between partial or complete oil changes.

- In the IP48, which is another harsh oxidation test where oil is heated to a temperature of 175C (347F) and held for 24 hours before measuring the change in viscosity as well as the resistance to degradation and formation of residues, TURBOFLO LV 32 showed cleaner test tubes and a low viscosity increase of 3.7%.

Varnish formation doesn’t have to be an ongoing challenge. With a new approach that prioritizes prevention, coupled with the right fluid and effective oil monitoring program, turbine oil can not only perform better, but it can also perform better for longer. n

—Neil Buchanan, PE is senior technical advisor for Petro-Canada America Lubricants Inc