Asset data is crucial in the power generation industry. Without it, utilities are forced to speculate about how long their assets will last, when they will need repair, and which strategies will maximize plant efficiency. With it, plant owners have the tools to drive down operational and maintenance costs while ensuring highly reliable power delivery.

Strategic Power Systems Inc. (SPS) is one company that has helped power plant owners, operators, and original equipment manufacturers (OEMs) in the power industry make better-informed business decisions on the performance and operational readiness of their equipment. SPS collects data from operating power plants, field service technicians, independent power producers, and independent service providers to the energy industry. It uses that data to deliver unbiased, third-party, industry standard performance metrics and benchmarking statistics. Its operational reliability analysis program (ORAP) and ORAP database offer a wide variety of detailed performance data.

Importance of Data

Databases of historical and real-time operational data like ORAP offer plant operators and maintenance personnel the tools and data they need to predict equipment performance and manage the reliability and maintainability of their capital-intensive equipment. This capability pays multiple dividends. For example, one part of SPS’s service tracks spare parts and records how old the parts are in operational age, how many times they’ve been repaired, and at what cost.

“A large fleet of assets might have tens of millions of dollars worth of spare parts,” said Tom Christiansen, senior vice president for SPS. “If that customer can save 10% in parts cost by managing their usage more efficiently, there is a big return on their investment.”

As market conditions change and technologies evolve, however, so too do the needs of the power industry. Initially, SPS compiled performance data in Excel files in a time-consuming and error-prone process. Today’s markets demand a more efficient data collection process and more accurate results.

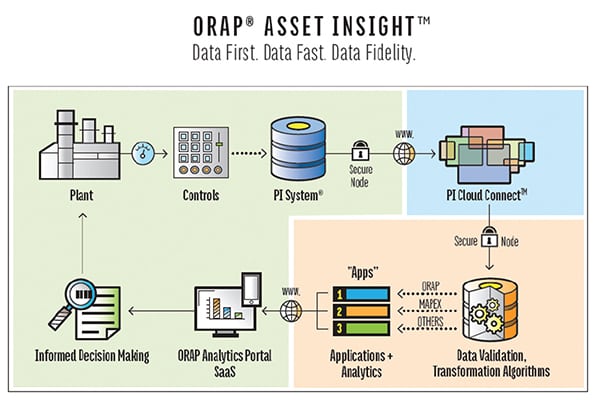

So, SPS formed a partnership with OSIsoft and MapEx Performance Monitoring to deliver a new level of data-driven solutions to the energy market, allowing intelligent data-driven decisions. OSIsoft’s PI System collects, analyzes, visualizes, and shares time-series data from multiple sources. MapEx adds state-of-the-art heat balance analysis and thermal performance evaluation to the SPS reliability database.

Working together, the three firms are taking advantage of automated data capture and transformation; advanced analytics; reliability, availability, and maintainability (RAM) benchmarking; and thermal performance monitoring to help customers minimize manual work, enhance data accuracy and fidelity, and gain timely access to performance metrics. A detailed operational history, including thermal performance, plays a key role in evaluating equipment condition and in setting maintenance intervals.

Linking Data to Decisions

In the past, it was difficult to correlate reliability with thermal performance because the data often resided in disparate databases. One of the most labor-intensive tasks in performing data analytics for reliability analysis is the effort to create a consistent set of data to submit to the analysis.

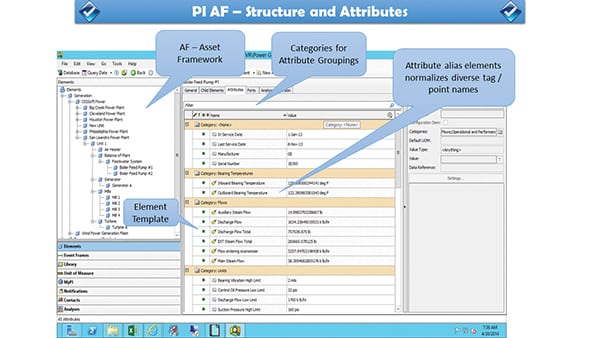

MapEx performance monitoring software uses the PI System’s Asset Framework to access measured data from multiple gas turbines at multiple sites without the need to know how the data was collected, the tag names, or the units of measure used at the sites. MapEx can calculate complex performance parameters, such as corrected power, heat rate, compressor efficiency, inlet airflow, and firing temperature, using identical analytics for each site. It can then report the results in the format that is familiar to the site. At the same time, an asset manager is able to pull up results for all sites in the same units of measure to simplify analysis.

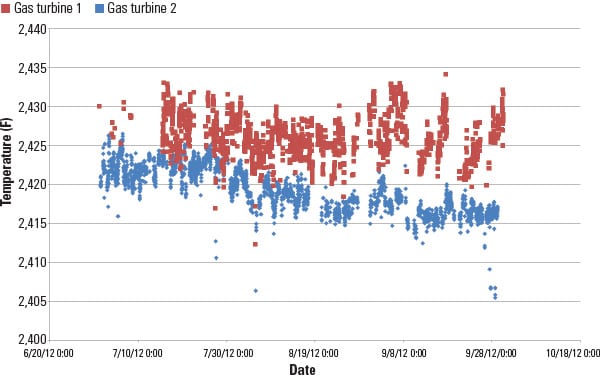

For example, Figure 1 shows MapEx-calculated baseload firing temperatures over three months for two gas turbines at the same site. The firing temperature of one of the engines decreased approximately 7F during the period.

This small drop in firing temperature degraded power performance by about 3 MW and increased heat rate by about 100 Btu/kWh. On the other hand, the lower temperatures reduce blade life consumption rate by about 10% according to the Larson-Miller relationship developed by GE. With this information, plant operators can decide to adjust the firing temperature control to recover performance or to operate at the lower firing temperature and lengthen maintenance intervals.

Plant operators save time by expending less manual labor in the data exchange process. Rather than dedicate a specific person to data reporting, the control system captures data automatically. Customers are able to respond to requests for data in minutes from any site using the same system. Questions about data validity and quality of the results are virtually eliminated due to the use of standard analytics and the removal of human guesswork from the data collection process.

Connected Services Agreements

One key to achieving SPS’s monitoring goals was the use of OSIsoft’s PI System via a connected services agreement. That allows SPS to use the PI System to remotely collect and manage data on an asset owner’s equipment. With the PI System operating as an open data infrastructure, SPS can use it to collect, archive, and distribute real-time and historical process data in a single comprehensive format. Once the real-time data is collected and integrated with historical process data, experts at SPS use their experience and advanced skills to analyze the data and transfer it into actionable intelligence.

Typically, a connected services agreement has two aspects: a technical framework and a business agreement. Under the technical framework, the agreement allows a service provider, such as SPS, to use its expert analytical and management skills to develop new data-driven services or enhance existing offerings. With the business agreement, service providers can work with multiple clients and distribute data to multiple stakeholders. Service providers, such as OEM aftermarket service teams, operations and maintenance service providers, and plant engineering and design consultants, can use a highly secure network that supports the use of more than 400 standard interfaces to remotely collect data from client-based assets.

The service provider uses the PI System to collect, analyze, visualize, and store real-time sensor-based operational data. Usually the system is housed in a remote management and diagnostic center alongside data center servers, networks, and storage assets, or in the cloud. It functions as an archive and central source of operating data and OSIsoft’s Asset Framework (Figure 2) is used to support simple, hierarchical access to real-time and contextual data. This capability allows service providers to implement analytics for asset management, troubleshooting, and predictive analysis, as well as to set up notifications and alerts.

https://www.powermag.com/efficient-use-power-plant-process-data-improves-asset-management/?pagenum=3