Steam turbines have to be warmed slowly to avoid excessive differential expansion of the various components, rotor stress, and potentially reduced service life. For that reason, startup times must be extended under certain conditions to allow gradual heating of components, which can prevent plants from starting swiftly and seizing spikes in real-time market prices.

Minnesota Municipal Power Agency’s (MMPA’s) Faribault Energy Park—a 285-MW natural gas–fired combined cycle plant operated by NAES Corp.—is one facility that struggled with just that problem. Its GE A10 steam turbine, rated at 117 MW, consists of a high-pressure (HP) turbine separated from combined intermediate- and low-pressure (IP/LP) rotor sections with both turbine inlets operated at 1,050F.

Originally, when the plant started up after more than 24 hours offline, it required some steam turbine warming time. If it had been offline for 48 hours or more, the plant would enter a cold-startup phase requiring even more warming, which severely limited the plant’s ability to adjust to market changes, start quickly, and capture price increases.

The plant’s turbine rotor, which measures roughly 30 feet long, expands by 1.25 inches in length as it reaches operating temperature. The turbine shell that houses it measures 3 inches to 4 inches thick in places and takes longer to warm and expand than the rotor. If the rotor and shell don’t warm and expand at a uniform rate, it can cause rubbing or binding between rotating and stationary components. If steam temperatures are too high or steam is admitted to the turbine casing too fast, the unit will automatically trip to prevent component damage.

With those limitations in mind, plant management began searching for a way to improve the unit’s operation. The goal was to minimize steam turbine warming time while keeping rotor stresses within allowable limits. The team wanted to reduce both startup costs and long-term maintenance expenses.

A Warm Turbine Is a Happy Turbine

The solution selected was a capital improvement project to install insulated electric heating blankets inside the steam turbine’s insulation (Figure 1) to provide a means of heating the turbine shell for startup as well as keeping it warm while offline in standby mode. Heating blankets (Figure 2) engineered and supplied by Team Industrial Services were installed on both the HP and IP turbines. Management decided that the LP portion of the IP/LP turbine operates at a low enough temperature that it didn’t need to be heated continuously.

|

|

2. Not your typical electric blanket. Blankets are custom-tailored with evenly distributed heating lines to ensure uniform heating of turbine sections. Courtesy: NAES Corp. |

The project components consisted of the turbine blankets, control cabinets, and distributed control system (DCS) integration. Total power required was approximately 200 kW, although the nominal consumption rate is less than 50 kW. Each turbine has multiple blanket heating zones, and each zone has three heater blankets installed for redundancy, which allows for some blanket failures without affecting the temperature of the zone.

Each zone has redundant surface thermocouples installed to monitor and control the blanket heaters, and each turbine has its own control cabinet for controlling each of the zones. The cabinets each house an integrated monitoring system that consists of current sensors, ground fault indicators, and stuck contactor indicators.

The control cabinets also include local-remote switches, hand off-auto switches, on/off lamps, and alarm-indicator lamps. Installers integrated the automation for the controls of each zone with the plant DCS and also wired the discrete outputs for turning the heaters on and off into the DCS. Heater status feedback, alarm indications, and on/off controls completed the integration with the DCS.

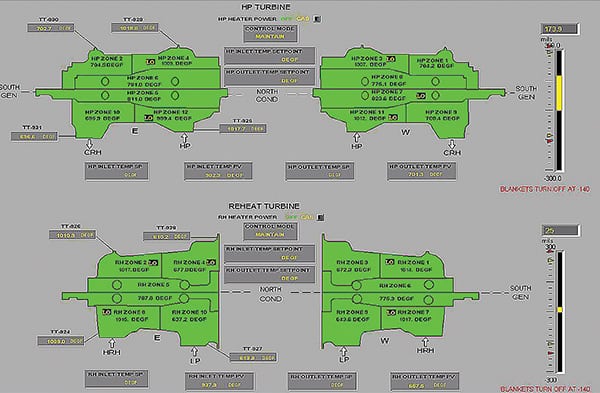

The control logic—developed by Novaspect—monitors local shell temperatures using a combination of newly installed zone thermocouples and the turbines’ deep-base thermocouples. The controls also monitor turbine differential expansion, turning off the heaters, when necessary, to prevent exceeding differential expansion limits. The various operating modes—maintain, warmup, startup, and cooldown—were integrated with the control logic.

Following project completion, operators now have the ability to enter setpoints and ramp rates (limited by the DCS) on graphical screens in the control room. Detailed graphical interfaces were used to integrate the heater control cabinets with the DCS, which allows optimal monitoring and control of the entire system (Figure 3) either from the control room or locally at the cabinet.

|

|

3. An integrated system. With zone thermocouples and new control logic, operators can enter setpoints and ramp rates on graphical screens in the control room. Courtesy: NAES Corp. |

A Worthwhile Investment

Installation of turbine heater blankets eliminated cold starts altogether and reduced warm startup times by nearly 50%. Even hot start times have been reduced by a small factor. All told, the blankets have helped the facility realize substantial fuel savings. They’ve also increased its chances of being dispatched in real time by offering in a unit with reduced start time. Maintaining higher steam turbine shell temperatures also reduces the stresses related to thermal cycling. That helps keep turbine components in optimal condition between maintenance cycles.

Before making any changes, management conducted extensive testing and reviewed the maximum permissible turbine shell temperatures to ensure that adding the blankets wouldn’t lead to trouble. The turbine, which dates from 2007, has a lot of instrumentation and gives operators the monitoring capability and logic to avoid heating parts of it unevenly and possibly creating a differential expansion problem. Not all turbines have the same capabilities, so results may vary at other installations.

While the project has been a great success overall, there were a couple of lessons learned in the course of installing the blankets, cabinets, and DCS integration. One is that blanket and wire installation must be closely monitored to prevent heater supply wiring from prematurely grounding due to its close proximity to hot surfaces. The other is that plants should expect some annual steam turbine insulation maintenance costs to replace failed or grounded blankets, because that will inevitably happen. ■

—Shawn Flake is operations manager of the Faribault Energy Park in Faribault, Minn., which is owned by MMPA and operated by NAES Corp.