They say you can’t teach an old dog a new trick, but sometimes you can upgrade your dog. Innovations, such as twisted tubes, expanded metal baffles, graphene-coated surfaces, and more are improving heat exchanger and condenser performance, making some upgrades worth considering.

Shell-and-tube heat exchangers have been around longer than anyone reading this article. The heat exchanger offers many advantages. It can be used in condensing, boiling, or single-phase applications; it can be utilized over a wide range of pressures and temperatures; it can be constructed from a variety of materials to meet corrosion and other design requirements; maintenance is fairly simple and straightforward; and it can accommodate various physical orientations.

However, there are some limitations to the design. The conventional shell-and-tube heat exchanger contains baffles on the shell side to provide support and direct flow through a circuitous course across the tubes. The downside is that low-flow areas, or dead zones, result in the vicinity of the baffles where fouling can occur, corrosion can go unchecked, and heat transfer is reduced. The directional changes caused by the baffles also consume energy, and the shell-side pressure decrease can be significant. The classic design is also prone to flow-induced tube vibration, which can ultimately result in failure.

Reinventing Heat Transfer

With these problems in mind, it’s not surprising that engineers have continued to conduct research to enhance the shell-and-tube design, resulting in new technology that improves heat exchanger performance, counteracts fouling problems, saves space, reduces cost, and increases efficiency. One group that is leading the way in this effort is Heat Transfer Research Inc. (HTRI).

Based in Navasota, Texas, HTRI is a research and software development company that tests various exchanger types and heat transfer surfaces. Its staff conducts application-oriented research on equipment and uses these proprietary data to develop methods and software for the thermal design and analysis of heat exchangers and fired heaters. Its research includes physical testing, computational fluid dynamics, and flow visualization.

“HTRI has and continues to investigate new commercialized exchanger types such as plate and shell or helical baffle exchangers,” said Joe Schroeder, senior vice president of technical programs for HTRI.

In the helical baffle heat exchanger that Schroeder mentioned, quadrant-shaped plate baffles are placed at an angle to the tube axis in a sequential arrangement to create a helical flow pattern. The helical flow design improves thermal effectiveness, enhances heat transfer, reduces pressure loss, lessens fouling, and significantly reduces vibration concerns. One manufacturer of the helical style, CB&I, says the design is well proven with more than 1,800 of its HELIXCHANGER heat exchangers in operation worldwide.

Expanded Metal Baffles

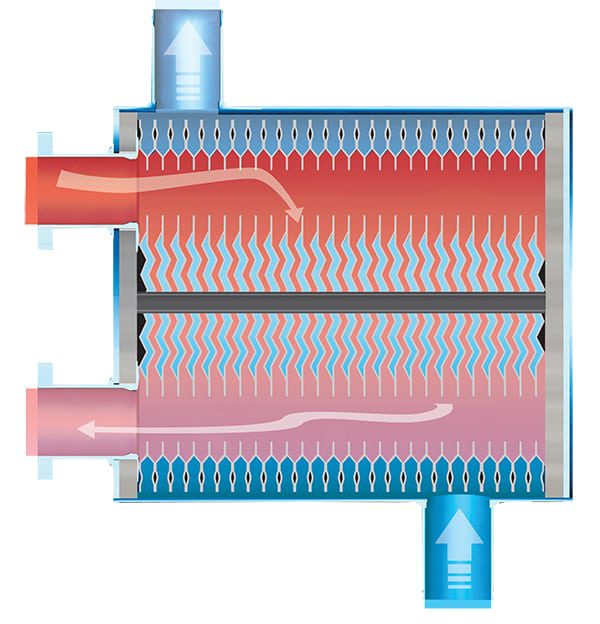

In addition to the helical baffle design, Schroeder noted that expanded metal baffles are also revolutionizing the industry. The design—patented by EMbaffle B.V., a group company of Italy-based Brembana & Rolle—features an expanded metal baffle grid made of plate material that has been slit and expanded (Figure 1). The expanded metal baffles create an open flow structure, allowing longitudinal flow on the shell side, which reduces pressure loss in the heat exchanger.

The shell-side fluid flows along the tubes and the flow area is constricted at each baffle cross, creating localized turbulence and increased velocity while breaking up the boundary layer around the tubes. The grid shape induces a local cross-flow component in addition to the longitudinal bulk-flow pattern, improving heat transfer characteristics of the heat exchanger.

Pressure loss is effectively converted into improved heat transfer as the boundary layer is repeatedly broken up at each expanded metal baffle along the length of the bundle (Figure 2). The company says that the ratio of the transferred heat to the shell-side pressure decrease in the EMbaffle design is significantly higher than that experienced in a heat exchanger utilizing a traditional baffle arrangement.

|

|

2. An open support system. The expanded metal baffle grid repeatedly breaks up the fluid boundary layer that forms along the tubes. Courtesy: EMbaffle B.V. |

Longitudinal flow is not intrinsically prone to flow-induced vibration, which can be a problem in conventional heat exchangers. In the expanded metal design, tubes are fully supported by a suitable number of expanded metal grids, with space between adjacent grids managed down to as little as 100 millimeters (less than 4 inches), helping eliminate any mode of tube vibration. In addition, dead zones found in segmental baffle heat exchangers are not present in the expanded metal design (Figure 3), which lessens fouling concerns and allows equipment to be operated longer between cleanings.

The company points to a concentrated solar power project that it provided equipment for in Spain as a successful power industry application of its technology. The plant’s oil/molten salt heat exchangers for its thermal energy storage system employ the EMbaffle design. Three expanded metal baffle heat exchangers were installed rather than six conventional heat exchangers, reducing the piping, valves, insulation, and heat tracing needed for the project. The solution also decreased the load on support structures and foundations, and reduced the volume of heat transfer fluid and molten salt needed for the system.

Twisted-Tube Heat Exchanger Technology

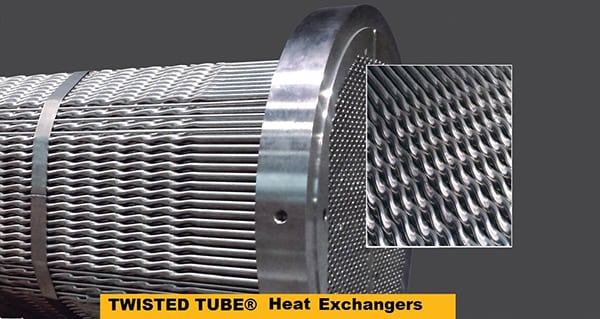

An interesting “twist” on the shell-and-tube heat exchanger is the twisted-tube design. Houston-based Koch Heat Transfer Co. says that its twisted-tube bundle technology offers many of the same benefits as the expanded metal design.

As the name suggests, twisted tubes are the novel feature of this design. The tubes are formed through a unique process, which results in an oval cross section with a superimposed helix, providing a helical tube-side flow path. The forming process is said to maintain a uniform tube-wall thickness, preserving the material’s mechanical integrity. The tube ends are round, however, to allow conventional tube-to-tube-sheet joints.

The Koch design avoids the need for baffles altogether. The helix-shaped tubes are assembled into a bundle on a triangular pitch, one row at a time, with each tube being turned to align the twists at every plane along the bundle length (Figure 4). In that way, each tube is firmly and repeatedly supported by adjacent tubes, which helps eliminate tube vibration. The completed bundle is then tightly strapped circumferentially to ensure no tube movement, resulting in a strong and robust module. The twist arrangement with gaps aligned between the tubes also provides clear washing lanes on the shell side, making high-pressure water lancing an effective cleaning method.

|

|

4. A new twist. Advantages of a new twisted-tube design include no need for baffles, which helps eliminate tube vibration, and easy high-pressure washing. Courtesy: Koch Heat Transfer Co. |

The company says the twisted-tube design provides a higher heat transfer coefficient than any other type of tubular heat exchanger for three reasons: The complex swirl flow on the shell side induces turbulence; the twisted tubes force a powerful tube-side turbulence; and uniform flow distribution extends the effective length of the bundle, providing more surface area than conventional shell-and-tube heat exchangers. According to some estimates, heat transfer coefficients with the twisted-tube design are 40% higher than those found in a conventional shell-and-tube heat exchanger with a similar pressure reduction.

The twisted-tube design is being used in the power industry for turbine steam condensing, boiler feedwater heating, and lube oil cooling, as well as other applications.

Graphene: Miracle Material?

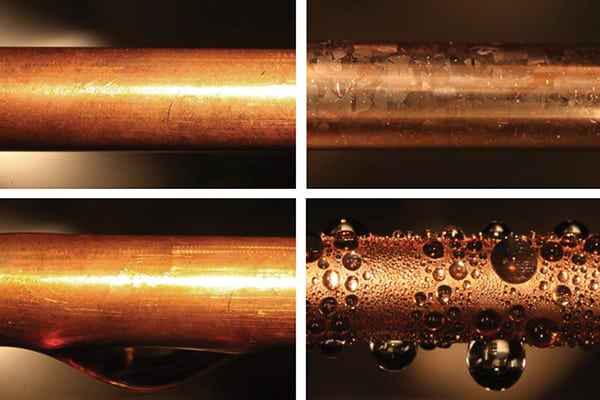

One heat transfer improvement that could be game-changing for the power industry has little to do with the physical design of a condenser, but rather with how steam condenses inside heat exchangers. Water vapor commonly condenses in two ways: It can form a film on wetting surfaces or it can form drops on nonwetting surfaces. When a water film is formed and coats the surface of condenser tubes, it impedes heat transfer, reducing efficiency. Therefore, promoting droplet formation rather than film formation is one way to improve condenser efficiency.

Recently, a team of researchers at the Massachusetts Institute of Technology (MIT) successfully tested the effectiveness of ultrathin scalable chemical-vapor-deposited graphene coatings in promoting dropwise condensation, while offering chemical stability and low thermal resistance. The idea is not completely new; polymer coatings have been used in the past to enhance droplet formation, but those coatings tended to degrade rapidly. When made thicker to compensate for the degradation, the heat transfer improvement was negated.

Graphene is the thinnest material known to man—just one atom thick—but it is also incredibly strong (about 200 times stronger than steel). It is very flexible and it is also an excellent conductor of heat and electricity, but it isn’t cheap. At a price of roughly $60 per square inch, graphene is currently too expensive to justify the cost of coating condenser tubes.

However, the MIT team demonstrated that a graphene coating could enhance heat transfer fourfold compared to filmwise condensation (Figure 5), and by some estimates that could lead to a 2% to 3% improvement in overall power plant efficiency. Improving efficiency by that amount would result in annual fuel savings of more than $1 million for the average coal-fired power plant. It could also help plants reduce emissions and meet Clean Power Plan requirements.

https://www.powermag.com/innovative-heat-exchanger-technology-enhances-proven-designs/