Selecting the most economical tube for a new condenser, or the retrofit of an existing one, is much more complex than mere price shopping. Each material has unique performance characteristics that affect the operating economics of the entire plant. A case study illustrates the importance of carefully choosing the tube material that is right for your plant.

Your selection of condenser tube materials either will pay handsome dividends or will be a drag on the operating economics of your plant for many years to come, whether you are considering a new condenser or retrofitting an existing one. Some materials used to manufacture condenser tubes are extremely expensive but will require little to no routine maintenance. Other selections are much less expensive up front, but experience has shown that they will require much maintenance and may even adversely impact plant output at times. In the worst case, copper transport from the condenser to other steam cycle components, such as boiler tubes (Figure 1) and steam turbine blades (Figure 2), can permanently reduce plant output. Removing copper from those components is time-intensive and expensive, especially when considering the cost of replacement capacity in today’s competitive electricity markets.

|

| 1. Boiler tube deposits. Alternating layers of deposited copper and magnetite on a boiler tube is shown. The source of the copper was the copper-nickel condenser tubes. Courtesy: Pacificorp |

|

| 2. Turbine blade deposits. Copper deposits on high-pressure steam turbine blades change the aerodynamics of the blade, causing a loss in steam turbine power generation. Courtesy: Pacificorp |

The good news is that making a fully informed decision about the most appropriate condenser tube material is not difficult, as will be demonstrated in a case study later in this article.

For the purposes of this discussion, let’s assume that your existing condenser is operating at design conditions, pumps are working perfectly, and the condenser is not experiencing the effects of air in-leakage or tube fouling of any type. In other words, the condenser is operating close to the plant’s original design conditions—the same as any freshly overhauled condenser with new tubes.

Determining the Best Value

Your choice of materials for new or retrofit tubing should be based on long-term costs and benefits, or a life-cycle cost analysis. In a true life-cycle analysis, the savings and costs are brought back to a project start date using a time-value-of-money analysis. Rather than get bogged down in those calculations, the case study in this article will take the simple approach of summing the annual costs or savings to produce a net long-term cost. Your internal evaluation process may require the more comprehensive economic analysis approach. If that is the case, the calculation process used below still provides you with a useful roadmap. In any economic analysis, project life is a key factor in determining the project’s economic promise. This case study assumes a 20-year economic life, a reasonable assumption even for coal-fired plants that were built 30 years ago.

The calculation procedure requires specific plant economic data, so you may also want to tweak the calculations to better reflect your particular circumstances. The cost data used in the case study are based on economic data collected during the summer of 2011. Also, you should have a copy of the 10th edition of the Heat Exchange Institute (HEI) Standards for Steam Surface Condensers available for reference. Many of the calculations used in the case study are described in more detail in that reference standard.

Condenser Case Study

Consider a 300-MW coal-fired plant built perhaps 30 years ago that uses a two-pass condenser with 16,400 one-inch outside diameter (OD) x 18 Birmingham Wire Gauge (BWG, 0.049 average wall thickness) 90-10 copper-nickel tubes with an effective length of 42.2 feet. The longest unsupported span in 46 inches, a length common to condensers designed during that era. The tube sheets are fabricated out of Muntz metal and will remain in place. Let’s also assume that the owners have invested heavily in other plant upgrades with the expectation that the plant has at least another 20 years of service life remaining. This baseload plant is expected to have an 85% capacity factor for each of those 20 years.

The condenser steam load is 1,480,000 pounds (lb) per hour with an enthalpy of 950 Btu/lb. On this unit, the turbine exhaust area is 375 square feet. The circulating water pumps provide a design flow of 114,000 gpm through the tubes. Tube scaling is minimized by good water chemistry control that produces an 85% HEI cleanliness factor. The condenser was designed for an inlet water temperature of 85F that, for the purposes of this analysis, is assumed to be constant.

In this case study, the repair of leaks in the original copper-nickel tubes occurs twice per year, predominately during the earlier years of the condenser life cycle. When nearing the end of the tube life, leaks develop much more often. In some plants, the high-pressure steam turbine must be cleaned due to copper plating on the turbine blades every four or five years, as is the case with the plant considered in this case study. (See “Steam Turbine Cleaning Using Chemical Foams,” p. 20.)

The cooling water is treated with ferric sulfate to assist repassivation of the existing 90-10 copper-nickel tubes. Because of the water’s aggressiveness, picking a new alloy resistant to high chlorides and microbiologically influenced corrosion (MIC) is of paramount concern. The original tubes lasted 20+ years, but because of a change in cooling tower operation and water source changes, the expected life of new 90-10 copper nickel tubing may now be only 10 to 15 years. Now is the time to make a new tube selection for the condenser.

The candidate materials under consideration for retubing are titanium grade 2, AL6XN high-performance austenitic stainless steel (UNS N08367), and SEA-CURE (UNS S44660) high-performance ferritic stainless steel. All have a proven record of accomplishment in both high-chloride waters, or have low MIC potential. TP 304 and TP 316 are not candidates for this condenser, as the chloride levels commonly climb to over 700 ppm and high manganese and iron levels provide high potential for MIC-related corrosion.

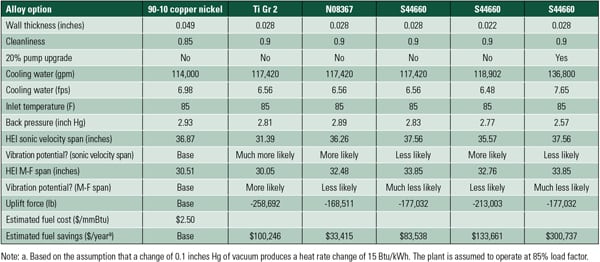

The HEI Standard is also an excellent resource for comparing the thermal and mechanical performance of the various tube materials. In addition to determining backpressure and the potential for condenser tube vibration damage, changes in uplift must also be evaluated. The results of the design analysis performed on this condenser are presented in Table 1. The following sections describe how the numbers were developed for each line item in the table.

|

| Table 1. Compare tube properties. Thermal and mechanical comparison of standard 90-10 copper-nickel tubes to alternative Ti Grade 2, N08367, and S44660 options. Source: Plymouth Tube Co. |

Wall Thickness. With today’s improvement in tube-to-tubesheet joint preparation and rolling techniques and improved-design stakes, a number of replacement tube wall thickness options are possible. Both the stainless steels and titanium have higher strength than copper alloys and do not require any corrosion allowance. Therefore, the use of a thinner wall is possible. Two other factors, however, must be considered: the tube-to-tubesheet joint pullout strength and vibration potential.

Traditionally, 22 BWG or 0.028-inch wall thickness was preferred for titanium or stainless steel retubing. Pullout loads of 1,200 lb to 1,600 lb are considered minimum. Higher-modulus/higher-strength tube alloys can have higher pullout loads than those with lower values of these material properties, even in softer tube sheets, such as Muntz metal. For example, with controlled tube hole preparation and torque-controlled rolling, tests have shown that 24 BWG (0.022 inch) S44660 stainless develops loads in a carbon steel tube sheet exceeding 2,300 lb.

Tests should be performed if a thinner material is to be considered. The final vibration analysis may also require the services of an expert in vibration analysis. In many cases, a vibration analysis finds that partial staking should be used.

Cleanliness Factor. HEI uses a cleanliness factor that ranges up to 100%, where 100% is a perfectly clean tube. The value selected in the analysis has a very significant impact on the results. Oxides that form on both the OD and inside diameter (ID) of the tubes act as thermal barriers and can lower the cleanliness factor.

In addition to tube cleanliness, a number of external condenser operational factors affect the value assumed, including air binding, restricted cooling water flow, and the impact of incompletely filled water boxes. Once in service, copper alloys have thicker OD and ID patina than the oxide films of stainless steels and titanium.

When scaling or fouling is not considered, the thicker copper alloy patina requires the designer to use lower cleanliness factors than with stainless steels or titanium tubes. After a few months of use, unscaled copper alloys with the OD and ID patina often exhibit 85% cleanliness, while a number of units that have used the stainless steels and titanium exhibit cleanliness of 90% or better. In many cases, the stencil on stainless and titanium tubes that have been in service for several years may still be visible.

For this analysis, a cleanliness factor of 85% is assumed for copper alloys and 90% is assumed for the remaining alloys.

Cooling Water Flow Rate Adjustments. Although the original design flow was 114,000 gpm, flow will vary as the inlet pressure changes. Low-head/high-volume circulating water pumps have high flow rate sensitivity to head (pressure). For example, the head decrease by changing to 0.028-inch wall thickness tubing from 0.049-inch wall original tubing can often result in a 3% increase in mass flow. We included that 3% in our calculations for 0.028-inch wall tubing and 4% for the 0.022-inch wall tubing. If available, the specific pump curve(s) for the plant should be used.

Cooling Water Velocity. Cooling water velocity is calculated from the cooling water mass flow. Although the cooling water velocity is normally considered to have a significant impact on condenser performance, the cooling water mass flow is the key factor for removing heat. Many older plants were designed with a 6.0 to 6.5 feet per second (fps) water velocity to prevent erosion-corrosion of copper-based tubing. With modern alloys, much higher velocities are possible. Table 1 includes the option of a water pump upgrade that increases the cooling water mass flow by 20% over the original design (the far right column).

Cooling Water Inlet Temperature. In this case study, we used the design inlet water temperature of 85F for all calculations. When the plant has a marginal condenser that limits power production during peak summer conditions, this calculation should be done using the maximum inlet water temperature for your analysis, as the material choice could have a significant impact on the project economic payback.

Condenser Backpressure. After the cooling water, steam flow, and tube alternative parameters have been determined, the saturation temperature is calculated and the backpressure is found by using the steam tables. A lower backpressure (or higher vacuum) increases steam turbine efficiency. HEI formulas predict backpressure improvement of 0.12 inch Hg, 0.04 inch Hg, and 0.10 inch Hg for 22 BWG titanium, N08367, and S44660, respectively.

In this analysis, the greatest heat rate gain without the pump upgrade was found using 24 BWG S44660, an improvement of 0.16 inch Hg. HEI calculations show 0.36-inch Hg reduction for the upgraded pump option. These last two performance upgrades are very significant.

Tube Span Calculation. Over the years, many different vibration methodologies have been developed to calculate a “safe span” that will produce no tube damage. The HEI Standard uses two methods to calculate a safe tube span length.

The first option, referred to as the tube spacing (ligament) method, assumes that the steam will achieve sonic velocity (either by very cold water, shutting down a waterbox, or by several other means), causing tube vibration. The tube span is adjusted to keep the vibration amplitude equal to or less than one-third of the tube spacing. The design allows for an additional clearance of one-third of the ligament, preventing tube-to-tube collisions.

The second method, extracted from the MacDuff and Fegler method (known as the M-F method), compares the natural frequency of the tube versus vortex shedding and fluid elastic whirling. To be conservative, the designer should use the shorter length predicted by the two calculation methods.

For this case study, the two HEI methods were very conservative, predicting lengths that are significantly shorter than with the methods used for the original condenser design. For this condenser, the M-F method developed the shortest span of all the tube choices. As the original condenser span was 46 inches, both HEI methods suggest that staking will be required regardless of alloy, including the 90-10 copper nickel replacement option. Tube vibration was not a problem on this condenser in the past, possibly because of the larger steam dome that was so common in older condensers. Your tube vibration consultant will help you make the final tube length decision and determine whether tube staking is required.

Uplift Force. Copper-nickel has the highest metal density of the common tube materials, so all of the new materials considered will result in a condenser with significantly less weight. The difference in pressure across the large turbine exhaust area can create a significant uplift force. When this condenser is at 1.5 inches Hg of backpressure, the uplift due to the vacuum is approximately 700,000 lb. If another tube is selected, the drop in tube weight could overload the supports and possibly damage the turbine. Switching to titanium tubing results in a weight reduction of 260,000 lb. A specialist should be consulted to determine if additional condenser foundation anchoring is required.

Estimated Fuel Savings. The change in steam turbine backpressure will have an impact on heat rate and, ultimately, the amount of fuel that will be consumed by the plant. This case study assumes the coal purchased over the 20-year analysis period costs an average of $2.50 per million Btu.

For this plant, we determined that for each 0.1 inch of Hg change in backpressure, the plant heat rate will change 15 Btu for each kWh generated (see the HEI Standard for more details). A fuel savings of $100,000 per year is estimated if 22 BWG titanium is chosen. When switching to the super-austenitic N08367, $33,000 per year in fuel savings results. The calculations find that S44660 saves $83,000 to $133,000 per year, depending on the tube wall thickness chosen. Adding the pump upgrade to the 22 BWG SEA-CURE saves $300,000/year versus the original 90-10 copper-nickel tubes.

All these factors are then summed to find the tube option with the lowest fuel consumption rate and, therefore, the lowest operating costs. The resulting operating cost estimates are shown in Table 1.

Calculating the 20-Year Cost Savings

The next step is to estimate the net capital costs of the upgrade. For this case study, the plant assumed a 20-year remaining life for the life-cycle economics calculation (Table 2). We also assumed that the plant chemists have a good handle on the cooling water chemistry that will keep the tubes free from scale and biological slime over the project life.

|

| Table 2. Twenty-year cost analysis of retubing a condenser with 90-10 copper-nickel tubes compared with alternative alloy options. Capital costs and savings estimates were estimated during the summer of 2011. A negative number represents a cost savings. Source: Plymouth Tube Co.

Budgetary tube costs were obtained next. During discussions with potential tube installers, we found that the cost to install the various alloys was not significantly different: The cost of installation was approximately $600,000 for all tube materials. The consultant recommended some staking, due to the lower stiffness of the titanium, the N08367 tubing, and the 24 BWG S44660. For the staking, our installers quoted an average of $250,000 for titanium, $50,000 for super-austenitic, and $75,000 for 24 BWG super-ferritic stainless steels, proportional to the amount of staking. The consultant was also concerned about the additional uplift if titanium were chosen. We included $50,000 in the budget for reinforcement of anchor points. With today’s high scrap prices for copper and nickel, the scrapped tubing has significant value. Assuming a thinner wall than originally installed, a $1,000,000 salvage credit was included. The high conductivity of the cooling water can result in galvanic differences between tubing and the Muntz metal tubesheets. To prevent attack of the tubesheet, we included installing a premium coating of a multi-layer high-solids epoxy, estimated at $165,000 for this power plant. When planned during installation, this type of coating combined with a small flare can also help to increase pullout loads at the tube-to-tubesheet joint. Copper-nickel alloys are galvanically similar to the Muntz metal; coating it is not required for that alloy. Part 2 of this four-part report on the condenser, “Improving Condenser O&M Practices” (p. 40), discusses the details of selecting and applying an engineered coating to condenser tubes. For the option that required a pump upgrade, the estimate included a $400,000 capital cost for rewinding the electric motors to produce more horsepower. An alternative, which is more expensive but much more flexible, is to switch to variable-frequency drives. At this point, the total capital expense for each of the tube materials is determined by adding and subtracting all the costs and credits. Next, we must include an estimate for operation and maintenance costs for the various tube candidates. In Table 2, based on the calculated backpressure differences used to develop the data in Table 1, we expect a fuel savings of $2.0 million over 20 years for 22 BWG titanium, $665,000 for N08367 and approximately $1.75 million and $2.67 million respectively for 22 BWG and 24 BWG S44660, compared with the 18 BWG copper-nickel base selection. Because of copper-nickel’s sensitivity to erosion-corrosion and H2S-related pitting, we expect to get an occasional tube leak, possibly from erosion-corrosion due to entrapped debris. We estimate that this will occur once per year during the first five years of service and twice per year after five years. Fortunately, this condenser is of a divided-flow configuration, so we do not need to completely shut down the plant down to fix the leak. Locating the leaks and plugging the tubes normally takes about 24 to 36 hours. During a 50% derate, the plant loses $225,000 of income, assuming $35/MWh as the price of the lost power sales. Because the other tube candidates are not susceptible to erosion-corrosion, no lost-power cost assignment is needed. Our traditional cost for chemical treatment (pH adjustment, ferrous sulfate treatments, and others) to protect the copper tubing has been about $100,000 per year. This treatment will not be required, or will be minimal, with the other alternatives. The row in Table 2 “Cost over 20 years” shows the sum of the installation, operation, and maintenance costs for each of the tube options. In this analysis, we addressed the impact of fuel cost by assuming the fuel for the original 90-10 copper-nickel as the base, and the fuel adjustments reported in Table 1 are included as either credits or debits. The numbers clearly show that the like-for-like 90-10 copper-nickel tube replacement is by far the least economic of the alternatives, particularly when lost production due to additional outages to fix tube leaks is included in the analysis. The combination of the derate costs required to fix tube leaks, water chemistry control, and additional cleaning required due to copper transport adds over $10 million to the cost directly related to using 90-10 copper-nickel condenser tubing over a 20-year life. Although the installation and tubing costs of the alternate materials are significantly higher, this increased cost is mitigated by the significant fuel saving (compared with the 90-10 copper-nickel option). Also note that this analysis assumes that the replacement copper-nickel tubing will last at least 20 years, a situation that is becoming less common due to today’s more aggressive water sources and the decrease in high-quality 90-10 copper-nickel tube sources. Copper-Free Steam Turbine EconomicsOne very significant performance penalty was not included in the 20-year analysis because not every plant that has 90-10 copper-nickel condenser tubes has the problem. Dissolved copper can plate in regions such as boiler tubes, desuperheating zones of feedwater heaters, and on high-pressure turbine blades, as discussed earlier. In lower-pressure units, the copper seems to favor boiler tubes; in higher-pressure units the turbine blades are preferred. In either case, a regular cleaning of the boiler to prevent unplanned outages, or cleaning of the turbine to reduce MWh loss, should be included in the evaluation. In this analysis, we’ve included a $250,000 cleaning every four years to cover the loss of power sales. This loss does not occur with the other tube material options. The last row of Table 2, “Lost power caused by copper plating on high-pressure turbine,” illustrates that copper deposits on high-pressure steam turbine blades can have enormous financial impact on the selection decision. Derates of 20 MW or greater are possible on a plant of this size after a four- or five-year period and must be accounted for in the economics of tube replacement. In the last line, we assume that the turbine derate caused by copper plating on high-pressure turbine blades is 5 MW average over four years before cleaning. Clearly, the magnitude of the lost capacity cost is enormous and can quickly overwhelm the other economic factors that would otherwise guide the tube metal selection. The results emphasize how important it is to keep the plant operating efficiently and the importance of keeping the turbine free from copper deposits. Pick Your TubeThe results from this case study are twofold. First, if copper plating in the steam turbine or boiler tubes is prevalent, then installing any of the tube material options will produce a simple payback of a few months. However, if tube replacement is necessary because the existing tubes have reached the end of their service life, then the S44660 will provide the greatest return on investment over a 20-year life, saving the plant over $16,000,000. Every selection process must consider site-specific criteria. However, the straightforward tube replacement analysis presented in this article shows that automatic like-for-like replacement may be a very costly decision when all of the important selection factors are considered. — Daniel S. Janikowski (djanikowski@plymouth.com) is technical manager of Plymouth Tube Co |

https://www.powermag.com/optimizing-condenser-tube-selection/