A West Coast combined cycle plant that uses reclaimed water found that cycling 300 times a year caused disruptions to the plant’s cooling water chemical treatment program. The solution was a performance-based monitoring and control system that uses available plant operating data plus algorithms to measure corrosion rates and fouling factors, which in turn allows the plant to trim chemical feed rates so they correlate with a specified corrosion rate, rather than a suggested chemical residual.

Combined cycle plant electrical generating efficiency is a function of many variables and operating conditions. For example, steam turbine generator performance is determined by the steam surface condenser efficiency and cooling tower performance. Deposition, whether organic or inorganic, in the high-efficiency film fill of the cooling tower negatively affects the evaporative cooling process and, hence, the tower’s performance. Deposits on the steam surface condenser tubes reduce efficiency as well.

The unique operating characteristics of a given plant also affect performance. The West Coast plant that is the subject of this case study, for example, cycles almost daily. That daily cycling, combined with the high ammonia and organic loading of the makeup water, can make management of the cooling water treatment program challenging.

Complicating operations at this plant is the source of its makeup water: treated effluent from publically owned treatment works (POTW). This means that there are strict discharge limitations for the water once it is used. For example, the plant maintains a nitrifying bacteria population in the cooling tower. Proper microbiological control requires delicate management of microbiocide application and is essential in order to control biofouling as well as corrosion in the plant’s circulating cooling water system.

As we explain in this article, a properly designed and implemented cooling water treatment program, in conjunction with reliable and accurate monitoring and control, is a prerequisite for good plant reliability and operating economics.

Overview of Plant Operations

The focus of this case study is a 550-MW natural gas–fired combined cycle electrical generating facility located on a 12-acre site in California. The plant provides steam and electricity to adjacent hosts under an energy purchase and sale agreement. The balance of the power is sold into the California power market. The power company also built a state-of-the-art recycled wastewater facility at the nearby POTW. There, secondary and tertiary processed sanitary waste effluent is treated with sodium hypochlorite before being supplied to the plant to satisfy makeup water requirements.

A partial seasonal analysis of the makeup water is shown in Table 1. Note that concentrations vary seasonally. Higher dilution occurs during the rainy winter season, and higher concentrations occur, along with higher ammonia and phosphate from agricultural operations, during the dry summer months.

|

| Table 1. Combined cycle plant makeup and cooling tower water analysis, as of March 11, 2011. Source: Ashland Water Technologies |

The plant uses an average of about 3 million gallons per day of reclaimed water. About 80% of the reclaimed water is used for cooling tower makeup and 20% is sent through the water treatment plant for further processing to produce makeup water for the heat recovery steam generators. The water processing system includes multimedia filters, ultrafiltration, carbon filters, reverse osmosis, and mixed bed demineralizer polishing. All of the regenerant membrane system’s reject and filter backwash is sent to the cooling tower.

The plant can only operate the cooling tower at a maximum of about 2.5 cycles of concentration due to environmental and governmental discharge limits for total dissolved solids and nitrite concentrations. This operating constraint leads to a relatively low apparent retention time in the cooling tower of about 16 hours, which means that the cooling tower blowdown is relatively large—approximately 900,000 gallons per day.

Even so, with 3 million gallons of reclaimed wastewater entering the plant each day, this represents about 70% overall recovery, or a reduction of over 2 million gallons per day of wastewater not discharged to the environment.

Previous Cooling Water Treatment Program

The previous cooling water treatment program consisted of stabilized phosphate, polymeric dispersant, and a powdered oxidizing biocide. Previous inspections of the condenser revealed biofouling with minor amounts of silt deposition. A liquid tetra potassium pyrophosphate (TKPP) product for cathodic corrosion inhibition was being fed to supplement the orthophosphate that was present in varying levels in the makeup water and provided anodic corrosion inhibition. The low retention time in the cooling tower was not allowing for sufficient reversion of the TKPP to a testable form of orthophosphate.

The incumbent service program did not include analysis for total inorganic phosphate (TIP) via digestion and was relying solely on orthophosphate testing to determine corrosion inhibitor chemical feed dosing. Although the service program used a polymer test to determine the amount of dispersant present, a key performance indicator (KPI) of filtered versus unfiltered phosphate was not being used. This test is necessary to determine if the amount of dispersant is correct for the plant’s operating conditions.

Although corrosion coupons showed adequate corrosion inhibition, no online monitoring of corrosion, fouling, or other key performance indicators was done. Consequently, chemical feed rates were excessive due to inaccurate monitoring.

The microbiological control program utilized a powdered oxidant (dichloro-S-triazine, sodium bromide) that was being slug fed once per day. No monitoring of the oxidation-reduction potential (ORP) occurred. Periodic microbiological assay slides showed results above 10 colony forming units (CFU)/mL, indicating that the microbiological activity was not being effectively controlled. Much of the biofouling was due to the high oxidant demand associated with the reclaimed water, especially the ammonia levels, which were as high as 40 ppm. Although the makeup water was treated with sodium hypochlorite at the POTW, it rapidly reacted with the ammonia [changed 10/19/15 as per authors] to form chloramines, which are far less effective as microbiocides.

The plant was also performing periodic shock treatments with a non-oxidizing biocide, isothiazolin, to help with microbiological control. Both the powdered oxidant and the isothiazolin can be effective in controlling planktonic bacteria, but they have little impact on sessile bacteria and accumulated biomass due to their inability to penetrate the biomass film. Under these conditions, without a proper microbiocide program, biofouling on the steam surface condenser as well as the high-efficiency film fill in the cooling tower can occur. The result is poor condenser and cooling tower heat transfer, which appears to plant operators as higher-than-design condenser pressure and reduced steam turbine power.

Condenser Inspection Found Deposits

The steam surface condenser was inspected May 18, 2010. A beige patchy hydrated deposition that increased in degree of accumulation from inlet to outlet was noted on the surface of the stainless steel supply (first pass) set of tubes. An underlying whitish dust/salt-like coating was also present on the stainless steel tube surface and was more evident closer to the inlet that had little coverage of the beige hydrated overcoat material. The same white material was noted on the stainless steel coupon pulled for microscopic inspection. The degree of accumulation on the coupon was far less, but the same morphology existed as compared with the boroscope photographs of the first-pass inlet condenser tubes.

Figure 1 shows the condenser in its “as-found” condition. Figure 2 shows the cleanliness of the condenser after the water treatment system discussed below was placed into service.

|

| 1. Before treatment. Source: Ashland Water Technologies |

|

| 2. After treatment. Source: Ashland Water Technologies |

The deposit analysis elements were converted to probable combinations, as shown in Table 2. Unassociated cations and anions were present in all the deposits. The cations were expressed as their oxides; however, their ratios suggested the deposits were neutral to alkaline. Deposits were biological in origin because they all contained excess loss on ignition (LOI/unburned carbon) that exceeded 11% to 12%. The LOI values ranged from 22% to 64%.

|

| Table 2. May 18, 2010, condenser west waterbox deposits. Source: Ashland Water Technologies |

Accumulated sodium and potassium from the microbes were also present. Such a deposit would be capable of capturing suspended and colloidal particles present in the high-velocity condenser cooling water. This is evident based upon the inorganic constituents found. The particles are likely derived from the backwashing of Title 22 water media filters into the cooling system. The alumina monohydrate is from the Title 22 treatment process. Ferric phosphate hydrate was from the filter aid/coagulant, ferric sulfate, added to the Title 22 filter water supply and the filterable phosphate from the Title 22 water. The total silica was not believed to be associated directly with all the alumina (the dirt/clay) because the Title 22 water alumina value and cooling water value mass balance exceeded that found in the cooling water. The total silica may result from the backwashing of filtered material, backwashing of filtered material into the cooling water, potential diatom manufacture of silica presence, or simply air scrubbing of windblown silt.

Operating Conditions Affecting the Treatment Program

The plant maintained a nitrifying bacteria population in the cooling tower for pH control and to help meet nitrite discharge limitations associated with the cooling tower blowdown. The plant maintains the nitrifying bacteria population because of the high ammonia content in the makeup water from the POTW and the consequent discharge limitations. Purposely maintaining a nitrifying bacteria population in the cooling tower is a very unique process and requires a delicately balanced microbiological control program. If too much biocide is fed, it kills off the nitrifying bacteria and leads to increased acid feed costs, exorbitant biocide costs, and, potentially, discharge violations.

When reviewing the makeup water chemistry, note that these water characteristics lead to a moderate to highly corrosive environment, especially as measured by the Larson-Skold index (explained below). The characteristics of this makeup water dictate close control of the cooling water treatment corrosion inhibitor program in order to meet specified performance targets. A short description of nitrification, denitrification, and the Larson-Skold index follow.

Nitrification. Nitrification is the two-step biological conversion process by which ammonium (NH4 +) or ammonia (NH3) is oxidized into nitrite (NO2 –) and then further oxidized into nitrate (NO3 –). In the first step, ammonia-oxidizing bacteria known as Nitrosomonas convert ammonia and ammonium to nitrite. Next, nitrite-oxidizing bacteria called Nitrobacter complete the conversion of nitrite (NO2 –) into nitrate (NO3 –) These bacteria, known as “nitrifiers,” are strict “aerobes,” meaning they must have oxygen to perform their work, which is possible in a cooling tower environment. The reactions are generally coupled and proceed rapidly to the nitrate form; therefore, nitrite levels at any given time are usually low. This is important to the power plant, which has a nitrite discharge limitation due to aquatic toxicity concerns.

The nitrification process also produces nitric acid as part of the bacteria’s metabolic processes. The plant maintains its cooling tower circulating water pH in the control range of 6.5 to 7.0 by utilizing the nitric acid produced to reduce scaling potential and to optimize the oxidant use. This also avoids the use of sulfuric acid feed, which minimizes potential exposure to hazardous acid and reduces the cost associated with acid purchase. Nitrosomonas and Nitrobacter are able to effectively nitrify with a pH of 6.5 to 7.0; however, the nitrification process stops at a pH below 6.0.

Denitrification. Denitrification is the biological reduction of nitrate (NO3 –) into nitrite (NO2 –) and eventually nitrogen gas (N2) by facultative heterotrophic bacteria under anaerobic conditions. Though these bacteria may prefer to use oxygen in their metabolic processes, under anaerobic conditions, they will extract oxygen from the nitrate, which reduces it to nitrite. Heterotrophic bacteria need a carbon source as food to live, and facultative bacteria can get their oxygen by taking dissolved oxygen out of the water or, as discussed previously, by taking it off of nitrate molecules.

Denitrification and associated anaerobic environments can also lead to elevated nitrite levels. Elevated nitrite levels are undesirable at this location due to environmental discharge limitations and aquatic toxicity concerns. Biofouling and accumulated biomass can produce and foster anaerobic reducing environments and thus should be properly controlled.

Larson-Skold Index. The Larson-Skold index describes the corrosivity of water relative to mild steel. The index is based upon evaluation of in-situ corrosion of mild steel lines exposed to Great Lakes waters. The index is the ratio of equivalent parts per million (epm) of sulfate (SO42-) and chloride (Cl–) to the epm of alkalinity in the form of bicarbonate plus carbonate (total alkalinity):

Larson-Skold index = (epm Cl– + epm SO4 2-)/(epm HCO3 – + epm CO3 2-)

The Larson-Skold index has been correlated to observed corrosion rates, and to the type of attack observed in a study of Great Lakes waters, and to makeup water sources of similar composition to Great Lakes waters. The index is useful as a predictive tool in evaluating the potential corrosivity of a particular makeup water source as well as the anticipated corrosivity of that water when cycled and treated in a cooling tower system. The index actually correlates the pitting corrosion potential associated with corrosive chloride and sulfate anions versus the amount of natural buffering provided by the total alkalinity in the water.

The Larson-Skold index might be interpreted by the following guidelines:

- Index

- Index >0.8 and

- Index >1.2: The tendency toward high corrosion rates of a local type should be expected as the index increases.

Water analysis and the equation above indicate that the makeup water for this power plant has a Larson-Skold value of 2.3, which means it is fairly corrosive. Within the circulating cooling tower water, the value jumps to 24.5 due primarily to the formation of nitric acid from the nitrification process. The nitric acid dramatically reduces the natural buffering capabilities of the water typically associated with bicarbonate alkalinity and puts a much greater demand on the corrosion inhibitor portion of the treatment program.

The previous microbiological program was not effectively controlling microbiological activity, as evidenced by high bacteria counts on assay slides as well as biofouling in the condenser. Although the cooling water treatment program was adequately controlling corrosion, it was not being monitored or controlled effectively, and chemical cost was excessive.

Improved Treatment Program

To ensure a smooth transition, and to better assess ongoing water chemistry, a performance-based monitoring and control system (controller) developed by Ashland was installed to simulate actual steam surface condenser conditions and provide real-time control of the cooling water treatment program. Prior to initiating the cooling water treatment program, background information was gathered and the unit was set up to duplicate full-load conditions of 6 ft/sec (1.8 m/sec) flow and 96F (35.6C) skin temperatures in the condenser.

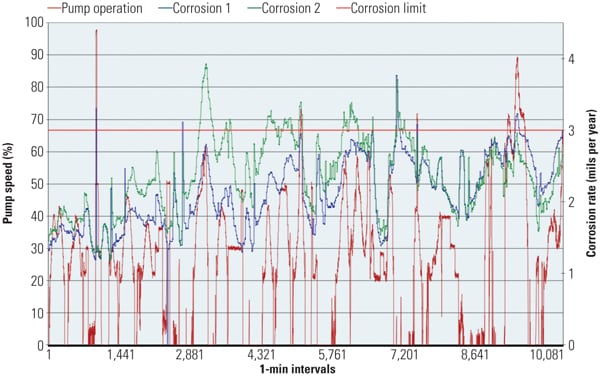

During this initial phase, other key operating indicators such as pH, conductivity, ORP, corrosion rate, and fouling factor were measured. This information permits the controller to feed the corrosion inhibitor and dispersant using a blowdown signal and to feed chemicals as needed to meet specific, predetermined control ranges (Figure 3). The unit used a feedback signal from key plant operating parameters, corrosion rate, and fouling factor to trim the chemical feed rates. Reducing the feed rates allowed the system to operate with lower corrosion inhibitor levels than had been used in previous programs. This reduction was possible because the controller was regulating chemical injection to meet a specified corrosion rate rather than meet a suggested chemical residual.

|

| 3. Managing chemical flow. Feedforward performance-based control allows tighter control of chemical feed. Source: Ashland Water Technologies |

The new cooling water treatment program consists of a stabilized phosphate program with a copolymer dispersant for phosphate stabilization. The sodium hexametaphosphate corrosion inhibitor allows for the proper reversion rate to a testable form of orthophosphate. The polyphosphate, therefore, provides cathodic corrosion inhibition while the orthophosphate from reversion, along with the variable amount of orthophosphate present in the makeup water, allows for anodic corrosion inhibition.

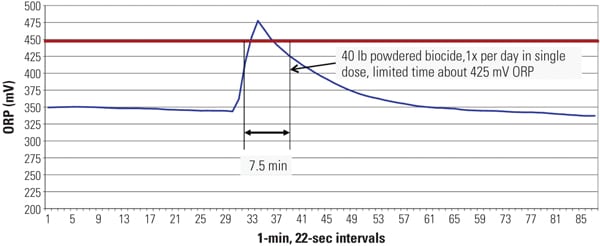

Furthermore, Ashland began testing TIP to further ensure that a potential overfeed situation was avoided, and the company also initiated a filtered versus unfiltered phosphate test to verify proper dispersant feed. As noted previously, for microbiological control, the plant had been feeding a single 40-pound dosage of a powdered oxidant once per day. Data from the monitoring unit showed that this was only elevating the ORP above 425 mV for approximately 8 minutes, as shown in Figure 4.

|

| 4. Too little time. A single daily chemical feed resulted in insufficient time at elevated ORP for adequate microbiological control. Source: Ashland Water Technologies |

As part of the new treatment program, Ashland recommended feeding a series of three 20-pound doses of the powdered oxidant at approximately 8-minute intervals, which allowed the ORP to remain above 425 mV for over 30 minutes, as shown in Figure 5. The microbiological dip slides improved from over 106 CFU/mL to below 103CFU/mL.

The performance-based monitoring and control system unit, which was outfitted with a modem to provide remote access to data, allows Ashland, as well as the power plant, to observe (and, if necessary, respond to) key operating and performance indicators in the cooling water system. In addition, the unit was programmed with alarm call-out capabilities: If a KPI were to get out of range, the unit would alert the water treatment company personnel and any designated plant personnel.

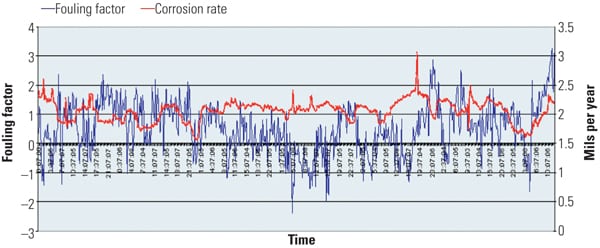

During the transition, corrosion rates remained below the target of less than 3 mils per year (mpy) and the fouling factor remained very low, as shown on Figure 6. All other operating parameters were met, and the target metrics established by the customer were satisfied.

|

||||

| 6. Hitting the target. Key performance indicators of corrosion rate and fouling factor both remained below established targets. Note that the general trend in predicted corrosion rate is similar to that of the fouling factor. Source: Ashland Water Technologies

The best example of the usefulness and effectiveness of performance-based monitoring and control is shown in Figure 7. While the corrosion inhibitor chemical was base fed according to preset control ranges on a feedforward blowdown signal (see Figure 1 for visual results), the proprietary feedback loop system monitored the actual corrosion rate in real time and adjusted the corrosion inhibitor feed accordingly, based upon that KPI.

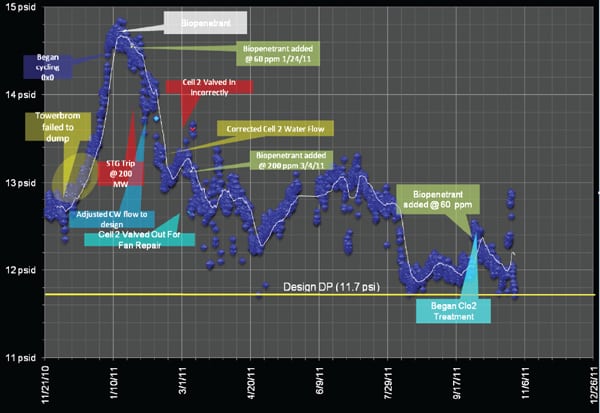

Biopenetrant Program OptimizationShortly after transitioning to the new, improved cooling water treatment program, the condenser was mechanically cleaned according to the routine maintenance schedule and also as a performance enhancement measure. About two and a half weeks later, the online ORP analyzer indicated that the powdered oxidant failed to feed into the cooling system. This prompted plant operating personnel to tie the output ORP signal from the monitoring unit into their distributed control system and to set up an alarm feature for the control room operators. However, the failed oxidant feed preceded a gradual rise in pressure drop (DP) across the waterbox of the condenser, indicating that a biofouling condition was building. Stainless steel mesh coupons confirmed the biofouling contamination. A proprietary biopenetrant was recommended, at an initially high shock dosage, to improve operating efficiency. The biopenetrant product contains a low-foaming surfactant and a dispersant for the released biomass, but it is also particularly effective on silt and dirt debris. Silt, as well as biofouling, had been identified as a deposit on an earlier condenser inspection report. The appearance of the cooling tower itself markedly improved within 24 hours. All wetted surfaces that had been covered with slime were virtually clean, and the DP across the condenser waterbox began to decline. A follow-up maintenance dosage of the biopenetrant was administered a few weeks later and, although the DP continued to fall, it still had not returned to the level it had been immediately after the mechanical cleaning and before it began to rise. The plant engineer noticed the DP reached a plateau and then rose again, so a second elevated shock dosage feed was performed. The results were remarkable and were directly associated with the removal of accumulated biomass and organic debris. The biomass was also an excellent medium for capturing any other suspended material that may have been present in the cooling tower circulating water, such as silt and dirt, which were released immediately following the biopenetrant feed. This was evidenced by a large amount of visible suspended solids in the tower sump and a brown appearance to the water; it was also confirmed by a drop in ORP that remained well below the previous background value of about 325 mV for a number of days before eventually recovering. The power plant made some mechanical changes to bring the system back to as steady a state as possible and to eliminate any variables, and the DP remained at the levels observed just after the mechanical cleaning (Figure 8).

|

https://www.powermag.com/performance-based-cooling-water-treatment/