Microbial inhibition, as part of a robust cooling water treatment program, presents a special challenge because of the variability in makeup water sources, plant processes, and discharge permits. Failure to maintain a proper microbial inhibition program will affect your bottom line as a result of heat rate degradation.

AEP’s Conesville Station, located in Conesville, Ohio, is a coal-fired conventional steam plant rated at 1,695 MW. The plant consists of six units, three of which (Units 4, 5, and 6) remain in service. The three active units were commissioned between 1973 and 1978. Like many plants of this vintage, the chemical feed systems are not as reliable as in the past and require additional maintenance. A loss in plant efficiency and output often results from a loss in chemical feed system reliability, particularly the plant’s biocide program. For example, loss in condenser performance is directly related to microbial growth on condenser tubes.

Units 4, 5, and 6 each use a closed cooling water system for their steam surface condenser, with makeup water coming from the nearby Muskingum River. Units 5 and 6 have separate cooling towers, but their basins are interconnected, making the two towers essentially one system. Unit 4 uses a separate cooling tower and recirculating system that is completely independent of the other units.

The plant had been struggling with maintaining its oxidizing biocide program for many years because of equipment deficiencies, as well as a dated chemistry application strategy. Consequently, the plant staff struggled with poor condenser performance that resulted in a higher-than-design plant heat rate.

The staff of Conesville recently performed a trial of ways to optimize the plant’s use of its current biocides to determine the cost savings of any improved microbial inhibition practices. The microbial control tests were conducted on the 780-MW Unit 4 cooling water system. The results of the trial, as well as how those results were used to justify the costs for new feed equipment, are discussed below.

Perform Pretrial Research

Pretrial investigation revealed that the plant’s poor microbial inhibition was caused by two principal factors:

- The chemical feed system was inadequate. The biocide feed system consisted of two pumps for each chemical that fed all three cooling towers via a common header. This configuration of cooling water piping did not allow for proportional, consistent feed of the biocide to each cooling tower. Consequently, it was nearly impossible to feed the appropriate amount of biocide to each tower.

- The water permits were restrictive. The original interpretation of the discharge permit suggested that the plant is only allowed to chlorinate 2 hours per day. During that time, the total residual chlorine (TRC) level in the outfall must be less than 0.2 ppm. At this feed rate and duration, the result was a gross underfeed of biocide, during which time the system was ripe for microbial growth.

Further review of the permit indicated that continuous chlorination was allowed, but the outfall TRC residual was decreased to 0.038 ppm. This meant that a dechlorination system on the outfall was a must.

Establish Trial Goals

The goals for the cooling water treatment trial included completing three specific tasks:

- Determine the efficacy of feeding oxidizing biocide continuously at low oxidant residuals. This approach will minimize the need for dechlorination at the outfall and protect the cooling system from corrosion due to elevated oxidant levels.

- Determine the lowest, continuous residual TRC necessary to maintain biological counts within the industry standard of

- Design a chemical delivery system capable of consistently supplying the necessary amount of oxidizing biocide, both bleach and CB70, to all three towers.

Trial Preparation

The plant staff installed a bisulfite feed skid before the trial began so that continuous chlorination was possible while complying with the discharge permit TRC requirement.

The bisulfite was fed into the blowdown stream whenever Unit 4’s blowdown was operating. The feed rate was manually adjusted because the concentration of the bisulfite did not track the blowdown flow rate. Rather, it was set to neutralize 1.0 ppm TRC at the maximum possible blowdown rate.

The operating experience along the Muskingum River suggested a daily usage of bleach in the Unit 4 cooling tower of approximately 300 to 600 gallons per day, which has a recirculation rate of 305,000 gpm and a system volume of 2 million gallons. The amount of bleach added also fluctuates with temperature, organic loading, and plant power setting. However, this range of expected bleach usage was a good starting point for estimating the theoretical size of the chemical feed systems. Also recall that this biocide program uses a bleach and stabilized bromine blend (CB70), so the actual amount of bleach used would be considerably less.

Testing and Data Collection

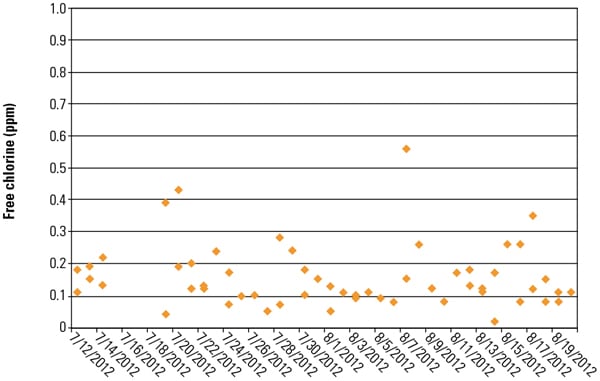

The trial period began July 12, 2012, and ran until August 20, a total of 45 days. The chemicals were manually fed with adjustments made based on the results of free chlorine testing because the existing feed system was incapable of continuously feeding the necessary amount of bleach and CB70 to maintain a target residual of 0.3–0.5 ppm. The temporary setup was sufficient to determine the efficacy of the proposed program and allowed the close monitoring of biocide inventories, which in turn aided in designing the ideal feed system for the application.

For chlorine measurements, the plant began using the standard Hach DPD method, as is typical in many applications. However, the fluctuating manganese in the makeup water source, which is known to contribute to interferences in the DPD method test results, produced inaccurate results. The decision was made to use the Hach amperometric test method (Hach AutoCAT 9000 Method) to ensure that there was no discharge of TRC beyond the permit limits. Along with free chlorine and TRC testing, microbial dipslide tests (to test for the presence of microorganisms in liquids) were performed weekly to track the effectiveness of the biocide treatment system.

Data collection consisted of downloading and aggregating plant historian data plus data from manual field tests. This historian data is critical, as it contains important information regarding overall plant operation, specifically condenser and cooling tower performance. Once the data is compiled and analyzed, the effectiveness of the biocide program can be quickly determined based on the performance of the very systems the program was designed to protect.

Review Water Chemistry

The target TRC was set as 0.35–0.5 ppm prior to the trial. However, biological monitoring using dipslides determined that a constant 0.15–0.2 ppm TRC maintained the bulk water biocounts well below the industry standard of less than 104 CFU/ml (Figure 1). Meeting the biocount standard is particularly challenging because the organically loaded makeup water from the Muskingum River can rapidly change, particularly during the hottest months of the year.

|

| 1. Free chlorine in water discharge.The chemical feed rate to maintain permitted residual chlorine levels in the discharge was established during the 45-day testing period, July 12 through August 20. Source: Nalco Chemical Co. |

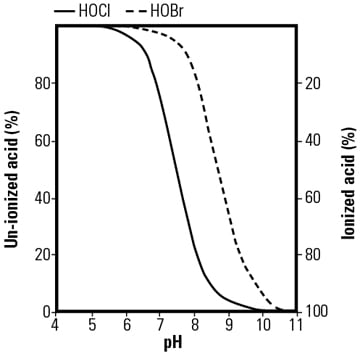

Understanding how the bleach and bromine chemistry control organics is important. As bleach is fed to water, it dissociates into hypochlorous acid and sodium hydroxide, NaOCl + H2O→HOCl + NaOH. The hypochlorous acid further dissociates into hydrogen and hypochlorite ion, HOCl ↔ H+ +OCl–, which is highly dependent on the pH of the water. According to the FILMTEC Reverse Osmosis Membrane Technical Manual published by Dow Water & Process Solutions, “The germicidal efficiency of free residual chlorine is directly related to the concentration of undissociated HOCl. Hypochlorous acid is 100 times more effective than the hypochlorite ion OCl–. The fraction of undissociated HOCl increases with decreasing pH” (Figure 2).

|

| 2. Bleach and bromine dissociation are very dependent on pH. Source: Preventive Macrofouling Strategies for Nuclear and Fossil Fired Power Plants, Edward W. Ekis, Jr., and Michael G. Trulear, Nalco Chemical Co. |

In practical terms, this means that as the pH increases, the amount of free available HOCl decreases. For example, a pH of 8.0, which is typical for cooling tower applications, leaves approximately 20% HOCl, with 80% as OCl–. Therefore, it takes considerably more bleach at elevated water pH to maintain a specified TRC. Said another way, the amount of bleach needed to control microbiological activity increases as the water pH increases.

Furthermore, when bleach reacts with organics, considerably less-effective biocides called chloramines are formed. Chloramines are derivatives of ammonia by substitution of one, two, or three hydrogen atoms with chlorine atoms. The possible reactions proceed as follows:

HOCl + NH3 – → NH2Cl + H2O

HOCl + NH2Cl → NHCl2 + H2O

HOCl + NHCl2 → NCl3 + H2O

On the other hand, bromine chemistry is appreciably different than bleach. Because bromine is typically used in conjunction with bleach, HOCl + NaBr → HOBr + NaCl.

As with hypochlorous acid, the hypobromous acid (HOBr) will dissociate into the hypobromite ion (OBr–), which, as with bleach, is also pH dependent: HOBr ↔ H+ + OBr–.

However, the percentage of available HOBr is much higher at elevated pH relative to available HOCl. Recall in the previous example, that at a pH of 8.0, there is approximately 20% HOCl, with 80% as the less-biocidal OCl–. At that same pH, there is approximately 80% HOBr, with 20% as OBr–, a marked improvement.

In addition to dissociation advantages, there are also two other notable benefits to using bromine chemistry: The short-term biocidal activity of OBr– is very similar to HOBr, and any bromamines formed have the same biocide effect as HOBr. These key factors make bromine a much more effective and persistent biocide. Using bromine allows the plant to maintain a much lower oxidant residual while maintaining an effective microbial inhibition program.

Years prior to this particular trial, plant staff and Nalco consultants performed a study that compared the performance of “bleach only” and “bleach/CB70 blend” options. The study concluded that the blended biocide program provided a more effective microbial kill at a much lower TRC residual. Based on the bleach and bromine chemistry discussed above, this should be expected, because the cooling towers typically operate at a pH between 8.4 and 8.8 (refer to Figure 2), and the Muskingum River organic loading can vary between 2 and 25 ppm. At this elevated pH and organic loading, it would take a considerable amount of bleach to reduce bio-populations given the amount of chloramines and OCl–that would be generated. Therefore, a bromine-based chemistry program was identified as the best choice to control microbial activity and produce a continuous, low TRC residual.

First-Rate Results

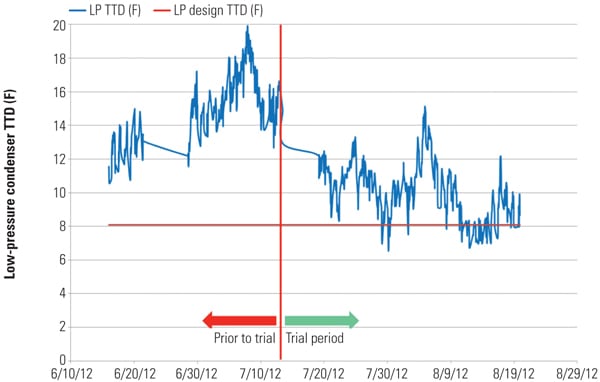

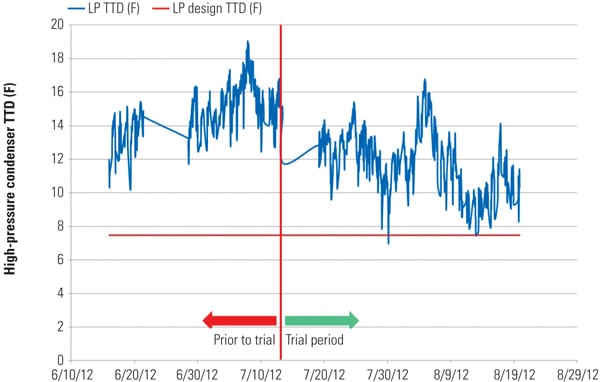

Conducting a plant performance test when control of the unit isn’t possible can be tricky. Consider the following when reviewing the data that follows. First, Unit 4 has a two-pressure, two-compartment, single-pass condenser, which means the cooling water flows first into the low-pressure (LP) condenser compartment and then through the high-pressure (HP) condenser compartment.

Also, around July 8 the cooling tower fan performance improved, which in turn improved the vacuum pump and air removal operation due to lower vacuum pump seal water temperature. This explains the sharp performance improvement a few days before the biocide trial began. Finally, as the biocide test began, Unit 4 was operating at less than 85% of rated capacity. It’s best to run these tests at rated capacity so the condenser is operating at design temperatures, vacuum conditions, and steam and water flow rates. When full rated load isn’t possible, it is common practice to use performance data when operating at 85% of rated load and higher, which reflects the data collected during the trial and used to prepare the following figures.

The figures of merit selected to present the performance improvement are the terminal temperature difference (TTD) and backpressure penalty (BP penalty), arguably the most important plant parameters when monitoring condenser performance. The TTD reflects the heat transfer efficiency across the condenser tube bundle and is usually affected by air in-leakage, scale, and microbiological growth. The BP penalty represents the steam turbine performance loss caused by poor condenser performance.

The historian data collected during the 45-day trial was processed using a specially developed condenser performance monitoring tool (CPMT) program. The CPMT takes the raw historian data and uses industry-accepted calculations to thoroughly analyze the condenser performance. The results of those calculations determine the actual cost of condenser performance degradation.

The split condenser requires careful consideration of the performance loss (TTD and BP penalty) imposed by scaling, air in-leakage, and microbial formation in each compartment. The losses can then be summed to produce the final lost steam turbine performance. There is also another important value in using these two metrics: They are calculated independent of each other. The TTD is calculated using actual measured parameters, while the BP penalty is calculated using different measured parameters as well as design data. This approach reduces the possibility of hidden interactions where common data sources are used.

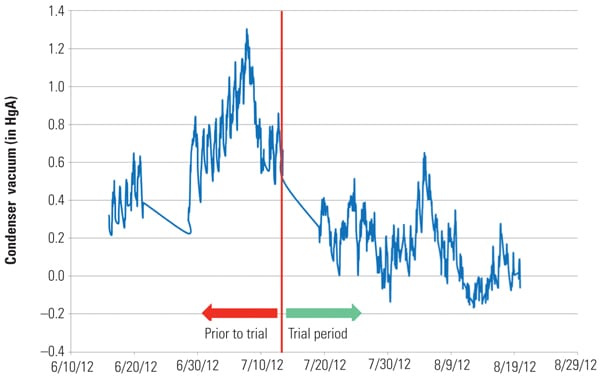

The data shows that the TTD began to improve shortly after implementing the biocide program (Figures 3 and 4). The design TTD is shown as a horizontal red line, and data above the line reflect a loss of condenser performance. During the trial period, confidence is high that scale control was maintained at normal conditions and there was no change in plant air in-leakage. Therefore, the improved TTD is a good representation of improved microbial control. More specifically, the data reflects effective removal and control of biofilm production. Also, both the LP and the HP compartments show TTD improvement, indicating that both compartments were experiencing significant microbial growth prior to the trial.

|

| 3. Low-pressure condenser TTD. Note the trend to lower condenser TTD during the trial, which indicates reduced microbial growth. Source: Nalco Chemical Co. |

|

| 4. High-pressure condenser TTD. Source: Nalco Chemical Co. |

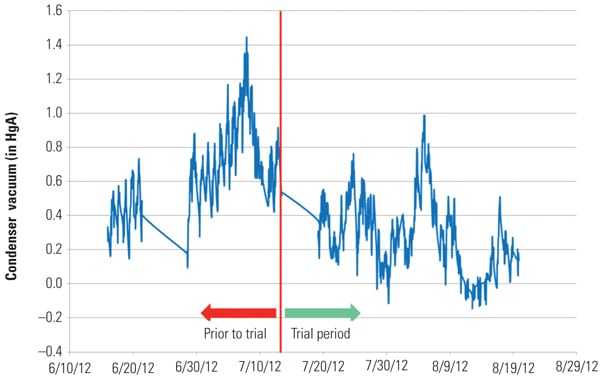

The BP penalty is calculated from many parameters, including condenser water inlet temperature, condenser heat duty, condenser tube characteristics, design cooling water flow, and the design condenser cleanliness factor. In other words, the design backpressure is determined assuming the condensers are clean, with no air in-leakage, and are operating under design conditions. The difference between the actual turbine backpressure and the backpressure corrected to design conditions is the BP penalty, or performance lost due to heat transfer degradation. Figures 5 and 6 illustrate the BP penalty trends during the trial. Note that these trends mirror the TTD results, thus confirming the improved performance can accurately be attributed to the biocide trial.

|

| 5. Low-pressure condenser BP penalty. Again, the trend to low backpressure (BP) during the trial indicates reduced microbial growth. Source: Nalco Chemical Co. |

|

| 6. High-pressure condenser BP penalty. Source: Nalco Chemical Co. |

Show Me the Money

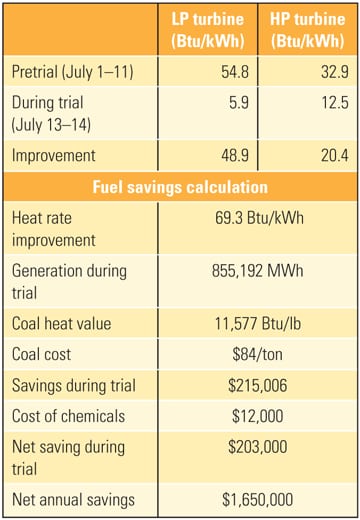

The table illustrates the summary data collected and processed during the test period, as well as the calculation procedure used to estimate cost savings. Based on the plant’s data and calculations, during the trial period of 45 days, the plant realized savings of $215,000 in reduced fuel consumption simply by improving cooling water biocide control. During this same 45-day trial period, costs for the biocide program were estimated to be approximately $12,000, producing a net savings of $203,000 during that 45-day trial period, or about $1,650,000 for a full year, assuming constant plant operations.

|

| Table 1. The economics of improved biocide use. The biocide tests delivered improved condenser performance and therefore improved plant heat rate, or reduced fuel consumption for a specified output. Source: Nalco Chemical Co. |

The impressive trial results enabled plant staff to obtain approval for installation of a new biocide feed system. In addition, the chemical feed configuration will be upgraded so that there are separate, redundant bleach and CB70 feed pumps for each cooling tower. The installed cost of the new system is approximately $106,000, which is less than the $203,000 cost savings enjoyed by only Unit 4 during the short 45-day trial period.

— Ryan Forbes (rjforbes@aep.com) is environmental and chemistry supervisor at AEP’s Conesville Station. Kevin Boudreaux (kjboudreaux@nalco.com) is an industry technical consultant for Nalco’s Power Business Unit. Aaron Haines (aahaines@nalco.com) is a Nalco district representative.