When U.S. President Jimmy Carter signed into law the Public Utility Regulatory Policies Act of 1978 (PURPA), he unintentionally ignited the worldwide deregulation of electricity markets, which in turn began a worldwide technology race between two distinct types of power plants: the newly created, industrial-scale plant that PURPA dubbed “cogeneration” and the traditional, utility-scale power plant known as “combined cycle.” Both types of plants teamed a gas turbine (GT) with a heat recovery steam generator (HRSG), but a very different GT-HRSG arrangement evolved for each plant. Let’s look at the evolution of each.

Cogen Plants

Cogen plants were designed to conserve the energy consumed—in both the heat and the electrical loads—at one specific industrial facility. For each of these “qualifying facilities,” as PURPA titled them, the cogen plant designer was to analyze the existing heat and power loads, and then select the class of GT that best matched those loads.

The best match for most facilities was an aeroderivative-class GT. Derived from the engines powering passenger jets, aeroderivative GTs were highly responsive, relatively small machines, generating from about 20 MW to 60 MW at the max of the class. The cogen plant designer then selected the HRSG that best matched the aeroderivative GT. The best match was often the small, single-pressure HRSG type, which used thin-walled components, and geometries allowing thermal expansion, to achieve a responsiveness akin to the aeroderivative GT.

Combined Cycle Plants

In contrast, combined cycle plants were designed to optimize electricity production for the nationwide utility grid. The best GTs for this purpose were the larger and more efficient frame-type units, commercially available in sizes greater than 200 MW.

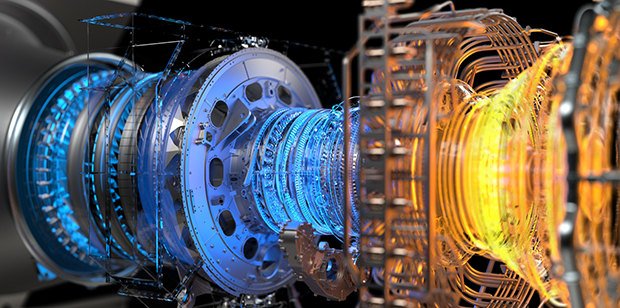

The HRSG that best matched this larger frame-type GT was the larger and more efficient, multi-pressure type of HRSG (Figure 1). These HRSGs were known to be less responsive than the small, single-pressure HRSGs, but they were expected to operate in steady-state baseload duty, so designers figured this lack of responsiveness wasn’t a big problem. However, it became a big problem when market conditions forced these larger, multi-pressure HRSGs into cycling duty.

1. Combined cycle HRSGs were formerly offered only in large drum-style designs, but now they are made as once-through steam generators too. Courtesy: Acuren Industrial Services

Combined cycle HRSGs started failing prematurely because of the thermal transients of cycling duty. When that happened, HRSG users started modifying their existing units—and original equipment manufacturers started tweaking their new designs—to make them more responsive.

For example, dampers were installed in the exhaust stacks and the gas turbine inlets to thermally “bottle up” the HRSG during outages and reduce thermal transients. Another useful modification was the upgrade of entire heat-transfer modules, using a more-robust chromium steel and a tube-bundle geometry that allowed for expansion and contraction. With these changes, the technology race got super tight.

The Best of Both Worlds

Electricity developers watched the race unfold and placed their business bets accordingly. Which team was going to win? Would it be the small GT/single-pressure HRSG or the large GT/multi-pressure HRSG? If it had been a boxing match instead of a race, we could have said it was a contest between a bantam-weight fighter and a big, bruising, heavyweight champ. The “Bantam Boy” had quickness going for him, but he was out matched in power and efficiency, while the “Combined Cycle Kid” had awesome power and efficiency, but was slow on his feet.

Now—four decades later—the contest between these two looks like it’s been decided. It’s not that one technology knocked the other out; it’s just that the distinction between the competitors has now blurred until its nearly invisible. Designers of cogen plants have adopted the best features of the combined cycles. And designers of combined cycle plants have adopted the best features of the cogens.

To illustrate my point, let’s continue looking at the changes in HRSG design since the PURPA days, and then we’ll look at the changes in GT design over the same interval.

OTSGs

As mentioned above, the HRSGs in cogen plants were designed for fast response to a facility’s fluctuating thermal loads, so they featured thin-walled components, or even eliminated steam drums, which were called once-through steam generators (OTSGs). The OTSG was the most-responsive HRSG made, but it was commercially available only in small sizes (below the aero-class cap of 60 MW). In contrast to the drum-type HRSGs of combined cycles, the OTSGs of cogen plants didn’t have defined economizer, evaporator, and superheater sections, nor did they have steam drums or blowdown systems. By removing these thick-walled components, OTSGs reduced the damaging stresses from thermal transients.

These damaging stresses from thermal transients suddenly became important to combined cycle designers when market demands forced their plants to switch from baseload duty to cycling duty. As a result, combined cycle HRSG designers also started using thinner steam drums. This change started blurring the line between the two competing technologies.

In 2016, the designers of combined cycle HRSGs blurred the line even further by introducing large HRSGs with no steam drums. The first of these large, combined cycle OTSGs came with the commissioning of the San Gabriel station in Batangas City, near the Philippine capital of Manila.

San Gabriel’s revolutionary OTSG was supplied by NEM Energy, under contract to Siemens Energy, which supplied the frame-type GT for the project—an H-class unit (Figure 2). The Siemens H-class GT also exemplifies how combined cycle designers borrowed the best features from cogen designers. Rated at a whopping 375 MW, the Siemens H-class GT was touted as “the largest operating GT in the world” when it first came out. Surprisingly, this combined cycle, frame-type GT features an air-cooled hot gas path that gave it fast startup and ramp rates, similar to those of an aeroderivative GT. According to Siemens, this GT can go from zero to full load in less than 30 minutes.

2. The Siemens H-class is a massive, frame-type GT, but it has the responsiveness that formerly could be found only in the aeroderivative-type GT. Courtesy: Siemens

Bigger Aeros

While we’re talking about the latest frame GTs borrowing the best features of the aeroderivatives, let’s look on the flip side and see how the latest aeroderivative GTs are borrowing the best features of the frames. The first example of this is the installation of multiple aeroderivative GTs at a single site, thus growing the plant’s capacity into the range of a combined cycle facility.

The Queen Elizabeth Station in Saskatoon, Saskatchewan, for instance, lined up six aero GTs and small HRSGs for a total plant rating of 430 MW, which somewhat blurred the line between the aero-type GT/HRSG team, and the frame-type GT/HRSG team. This year, the leading supplier of aeroderivative GTs blurred the line even further when it introduced the largest aero GT ever. GE Power’s LM9000 (Figure 3) produces 65 MW, thus breaking the aero-class size barrier of 60 MW.

3. The GE LM9000 is the largest aeroderivative GT ever built, rated a class-busting 65 MW. Courtesy: GE Power

So, if cogens are now as large as combined cycles, and combined cycles are now as responsive as cogens, just who was the real winner of the power plant technology race? The winner was—drum roll, please—the electricity consumer! Thanks to the unintended technology race profiled above, and the invisible hand of free markets, consumers worldwide now get their electricity from power plants that are larger, more energy efficient, and more responsive than anyone back in the PURPA days could have dreamed.

To learn more about HRSG, gas turbine, and steam turbine technology improvements, come to the HRSG User’s Group conference, April 24–26, 2019, co-located with the ELECTRIC POWER Conference and Exhibition at the Mirage Events Center in Las Vegas, Nevada. Visit https://2019.electricpowerexpo.com/hrsg/ to learn more and to register.

—Rob Swanekamp, PE is executive director with HRSG User’s Group Inc.