Studies and surveys have predicted a future shortage of skilled workers in the power industry for many years. Unfortunately, the future is here. When qualified workers are difficult to locate, some companies are finding that technology and service contracts allow them to do more with less.

It’s no secret that the traditional power industry workforce is aging, and as individuals retire, some companies are finding that replacing them is difficult. Consequently, managers are forced to look for new ways to pick up the slack left by departing workers.

Companies regularly search for ways to increase productivity. Improvements often result from technological innovation, but changes to work practices and procedures can also streamline activities, leading to better results. Although it is often true that time can be managed more efficiently, there are limits to what can ultimately be achieved through time management measures.

At some point, workers are forced to focus on high-priority tasks while postponing, and in some cases even canceling, less-important work. Eliminating unnecessary tasks is a worthwhile exercise, but once all of the “fluff” is removed, the work that remains must be completed. The question many managers are asking is: What is the best way to utilize technology and external resources to get the most bang for the buck, thereby allowing in-house personnel to focus on day-to-day priorities while specialists concentrate on the more intricate details?

Getting Help from the Outside

Turning to contractors for assistance is nothing new, but some of the latest technology makes the option more attractive than ever. SKF USA Inc. is probably best known as a bearing manufacturer; however, it offers quite a bit more than just bearings. The company also provides such things as sealing solutions, lubrication systems, electromechanical applications and services, asset efficiency optimization, and integrated condition monitoring, which can generate a lot of data.

For many facilities, obtaining data is not necessarily the problem; it’s understanding and making sense of all the information that is available. Greg Toomey, an expert in SKF’s Traditional Energy business unit, noted that staffing at power plants is much different today than it was even 10 years ago. Facilities used to have a lot of analysts and people dedicated to looking at all the condition-based maintenance information, but as personnel have retired—and continue to retire—capabilities have changed. Frequently, best practices were not formalized and documented, so the knowledge walks out the door with the retirees.

Toomey believes that plants need to do three things with their data, which he calls the three I’s:

■ Integrate. Gather all of the data, such as vibration monitoring, oil analysis, and operator round data, so that it can be reviewed collectively in a single location.

■ Interface. Tie the data into other systems, such as the distributed control system and the computerized maintenance management system.

■ Intelligence. Create some level of understanding about the data, so that it’s not just a meaningless collection of numbers.

“When you start getting all of this data, the thing you want to do is make sure that you’re making decisions based on all the pertinent data relative to asset health of the component you’re looking at, whether it’s a pump, a motor, or whatever,” Toomey said. “Then you have to have a process in place for people to manage based on condition.”

Toomey said one of SKF’s services includes assessing a company’s work management process flow and then conducting a maintenance strategy review to align maintenance tasks with business goals. He said that some equipment is obviously critical, but there are also a lot of components that many people don’t realize are critical to business goals, particularly in the instrumentation and electrical areas.

Maintenance Agreements

Among the most familiar ways of managing plants with smaller staffs is the use of maintenance agreements. Original equipment manufacturers (OEMs) frequently offer long-term service agreements (LTSAs) to their customers. An example of this is provided by the member-owned cooperative utility Matanuska Electric Association (MEA) headquartered in Palmer, Alaska. In December, MEA signed a technical maintenance agreement with Wärtsilä North America Inc. to support its new 171-MW Eklutna Generation Station (Figure 1), located about 20 miles northeast of Anchorage.

Under the five-year agreement, Wärtsilä will provide support for the condition-based monitoring services, remote troubleshooting, spare parts, technical labor, and computer maintenance management for the new power plant. Advanced diagnostics for the 10 Wärtsilä 50DF dual-fuel 18-cylinder engines (Figure 2) is also included.

“One trend we have seen in the last couple of years is that many customers want to outsource the operations and maintenance, even if they have been operating for a long time,” said Kaj Nordman, Wärtsilä’s business development director for power plant agreements. Nordman noted that several plants in Indonesia are now considering operations and maintenance (O&M) agreements with his company.

One of the benefits of signing an agreement is that Wärtsilä performs a plant audit and assessment when it arrives. Based on the results, various upgrades are proposed for the customer. Some examples of improvements that are frequently recommended include upgrades to automation systems, cooling systems, and to the engines themselves to increase output and efficiency. Nordman said the service has been very successful.

Advanced Monitoring

According to Jeff Fassett, owner of IEM Energy Consultants Inc., independent power producers are the ones that tend to rely on third-party O&M agreements the most. One of the services IEM offers is the development, bidding, and evaluation of O&M contracts. However, Fassett said a lot of U.S. companies are in a “wait and see” mode.

“Everyone’s deathly afraid of being regulated right now,” Fassett said. “They don’t know what some of these new rules are going to do to the industry—where the government’s going, what the Environmental Protection Agency regulations are going to do.”

Fassett is working on a couple of contracts overseas in the meantime. One thing that he is a big fan of is monitoring and diagnostics services. As touched on previously, most OEMs offer LTSAs with options for offsite monitoring and diagnostics, but Fassett said there are now options available for non-LTSA customers.

Proficy SmartSignal, a product available through GE Intelligent Platforms, is a favorite of Fassett’s. He said the service is reasonably priced and that the company does an incredible job of data analytics. The system uses a type of neural network to train itself on plant-specific equipment, looking beyond first-order modeling to second-order parameters.

For example, when a lube oil temperature is out of specification, the monitoring system will evaluate other associated parameters compared to typical values, just as a skilled operator might do. But Fassett believes SmartSignal, and systems like it, have a much greater capability to catch incremental changes in operating parameters than a human operator can catch with a control system.

“I’ve been very impressed with the capabilities of SmartSignal and recommend it to many, many of my clients,” Fassett said.

Expert Analysis

Vibration monitoring is another technology that has come a long way. SKF offers a cloud-based service that basically manages customers’ vibration monitoring programs. The service can be tailored in various ways using permanently installed monitoring equipment, uploading portable readings taken by plant staff, or having an SKF technician collect data locally.

Toomey said the data is collected, put up on the cloud, analyzed, and customers can access it in detail. Utilizing the information, customers can act based on SKF direction, which includes a decision support tool.

“I kind of look at it as a vibration-level-two guy-in-a-can, if you will,” Toomey said. “We built models that will actually look at the spectrum data, not just overalls, and tell you whether it’s misalignment, imbalance, bearing problems, lubrication, etcetera, etcetera.”

For example, imagine that a feed pump is starting to develop an unusual vibration. The analysis points to inadequate lubrication, resulting in a bearing problem. Toomey said the integration step discussed earlier could offer managers oil analysis data, right there on the same screen, to corroborate or contradict the vibration results.

Additional information, such as pump performance testing data, could be cross-referenced as well, which might show signs of impeller wear, for example. The overall picture that the system paints can help to improve the maintenance decision-making process.

Lean or Understaffed?

Fassett sees a disturbing trend in staffing. He said he understands that all companies are trying to keep costs down so that they can be competitive in the marketplace, but he has seen instances where it has come back to bite facilities. In many cases, the preventive maintenance (PM) program is what gets forgotten.

Neglecting PM items doesn’t usually result in immediate problems. It takes time for issues to arise and start causing trouble. Fassett said he finds a lot of the same problems at many of the facilities he visits.

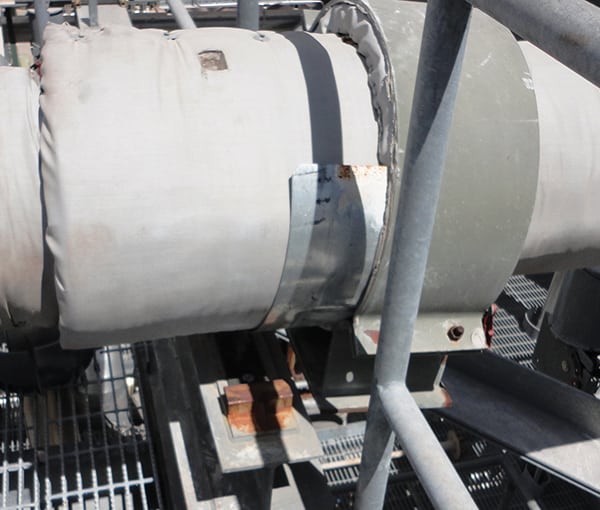

For example, most managers believe they have a comprehensive PM program for their high-pressure piping systems, but when Fassett inspects a site, he often finds spring can hangers that are beyond their limits and pipe support sliding shoes that are out of their guides (Figure 3). Pipe stress is a big concern in the long run. Not only can it affect some of the most important equipment in a plant, such as steam turbines and pumps, but it can also result in catastrophic failure.

|

| 3. Slip sliding away. High-pressure piping must be properly supported to minimize stress on all plant components. Courtesy: IEM Energy Consultants Inc. |

“I think it is generally a case of limited resources,” Fassett said. “To do a high-energy piping system audit and PM program, it usually takes outside resources.”

Fix It Now or Fix It Later

Technological advances are saving costs and reducing manpower requirements in other ways as well. There are some relatively simple inspections that can be done now to prevent much larger, resource-intensive problems down the road.

Fassett recommends enhanced infrared thermal imaging to many of his clients. In most cases, a one-time investment is required for the installation of infrared viewports on a plant’s switchgear and generator lead boxes, such as those manufactured by FLIR Systems Inc. (Figure 4) or IRISS Inc., but Fassett believes the cost is well worth it.

“Doing an infrared inspection of the generator lead box while at load will identify problems with lead box connections and cracking in the insulation—problems that won’t necessarily be identified when the unit is down and cold,” said Fassett.

Problems in these areas often go unnoticed until there is a serious breakdown, which can cost huge sums of money and require extensive downtime to repair. Having an installed viewport allows conducting an inspection in conjunction with annual infrared testing. If problems are identified, repairs can be scheduled when it’s convenient.

“It’s something that hasn’t been available all that long,” Fassett said. “Technology has evolved a lot over the last 15 to 20 years, and many facilities are missing the mark by not utilizing the technology effectively.”

Money-Saving Trends

“Cost cutting is very common today,” Nordman acknowledged. “Plants try to get down to the bare minimum, but even with external support and remote monitoring, you still need to have people at the site.”

Nordman said that 10 to 15 years ago, a common estimate was that one person was needed for each MW at its facilities, but not anymore. Now it is far fewer. Nordman pointed to a 360-MW plant in Ghana, Africa, where Wärtsilä is proposing a full O&M agreement with a staff of 85 people, but he suggested that plants in more developed countries may be able to get by with even fewer workers.

Condition-based maintenance and remote monitoring have helped reduce the number of people needed to operate and maintain plants. Data can be analyzed and predictions can be made based on trends and knowledge of similar equipment.

Wärtsilä has seven contract centers around the globe to provide support, with three more in the planning phase. With the knowledge gained by having more than 500 asset management and maintenance agreements, the company has been able to develop tools to increase availability and reliability, and optimize heat rates.

Remote support specialists target several improvement opportunities for owners and operators, including reducing maintenance costs, reducing fuel consumption and emissions, and avoiding unplanned stops. Wärtsilä does this by using models to calculate ideal operating parameters for installations.

Engine specification and installation type, ambient conditions, design criteria, and installation-specific data and configuration are analyzed and feedback provided to owners in a detailed report. Wärtsilä’s vast database of knowledge and experience allows required maintenance to be predicted two to six months in advance, and critical cases to be identified as early as seven to 30 days in advance.

Some risk is involved when remote connection via computer is allowed, but Nordman noted that Wärtsilä takes that threat seriously. “We have a department that specializes in cybersecurity, and they ensure we are meeting the highest standards and customer demands in that respect,” Nordman said.

Road Warriors

Large facilities—such as most nuclear plants and many large coal-fired stations—have been using outage contractors for a long time. It just isn’t feasible to staff a facility for seasonal fluctuations, but contractors offer benefits other than just a massive influx of people.

According to Ross McConnell, senior vice president of nuclear operations for Day & Zimmermann (D&Z), performing maintenance and modification services on 49 of the 99 operating nuclear units in the U.S. enables his company to benchmark performance and capture best practices from many different sites. The knowledge is shared with its customers for the benefit of all.

“Our customers value the breadth and depth of our experience, our industry footprint, and our ability to bring lessons learned from other companies,” McConnell said. “They value the level of engagement that they get from our leadership team.”

Although contracting for services is not a new concept, McConnell said that customers lately seem to want a contractor with a flexible delivery model, the ability to provide supplemental contingent workers, the capability to manage task work and project work, or a scalable combination of all three.

Providing engaged and well-trained talent takes work. D&Z uses a process called “blueprinting” to help. The company assesses the labor needs for all of its clients in a given region over an 18-month period and then creates a blueprint with a continuous employment opportunity available for workers. This process is vital to D&Z’s ability to recruit and retain skilled workers.

“We understand the challenges that our customers and the power industry are facing, and we think it’s increasingly necessary for us to take a true partnership approach with our clients to try and solve those challenges. We want to collaborate with our partners so that they can have the best results possible,” McConnell said. “They’re looking for us to do what we do best so that they can do what they do best.”

People Make the Difference

You often hear managers say: “Our people are our most valuable resource,” and even though it sounds cliché, the fact is that dedicated and enthusiastic employees do make a difference. There may come a time when computers and robots do some of the jobs that people currently perform, but most likely people will still be needed to oversee such programs.

“As much as the industry would like to rely on technology, I don’t think it’s ever going to get to the point where people are completely eliminated,” Fassett concluded. “I just can’t emphasize enough the need for having highly trained, motivated personnel to be onsite.” ■

— Aaron Larson is a POWER associate editor.