The Environmental Protection Agency’s emission factor resource, AP-42, is not your only option for developing particulate matter (PM) emission rates. Results of a prominent PM emissions measurement research program for gas-fired plants have been successfully used to support development and application of alternate PM2.5 emission factors by both regulatory agencies and permit applicants

The regulatory requirements for particulate matter (PM) species, most notably PM with a diameter of less than or equal to 2.5 micrometers (PM2.5), have become increasingly more rigorous in recent years. At the same time our technical understanding of stack PM emission species and measurement methods has grown significantly. However, the commonly used PM emission factors for gas-fired combustion sources, developed by the U.S. Environmental Protection Agency (EPA) in the late 1990s and published in the EPA’s emission factor resource, AP-42, have not been revised or “upgraded” since that time to reflect our advanced understanding of PM emissions and their proper measurement.

The accurate measurement of stack PM emissions using EPA standard or reference test methods has always been a challenge for gas-fired combustion units. The newest combustion units on today’s market are extremely efficient and emit minimal amounts of PM when firing gas. Comprehensive research studies sponsored by both governmental and private entities conducted after publication of the AP-42 emission factors have provided valuable information regarding the nature and magnitude of PM2.5 emissions formed by natural gas combustion, while identifying significant deficiencies with the measurement of in-stack PM2.5 emissions using the EPA reference test methods. Changes have been made to the test methods to attempt to address these deficiencies; however, method results still do not provide a real-world representation of PM emissions from gas-fired combustion units.

Use of AP-42 factors result in a significant overestimation of PM emissions from gas-fired combustion units, which leads to many unnecessary permitting and regulatory planning complications. A proposed source could be inappropriately designated a major new source or major modification under the Prevention of Significant Deterioration (PSD) and/or Nonattainment New Source Review (NNSR) rules. Such a designation, based on the overestimated emissions, will subject projects to significant additional permitting requirements, which could involve unnecessary complications in demonstrating compliance with National Ambient Air Quality Standards (NAAQS) for PM2.5.

In addition, for air quality standard attainment and maintenance planning purposes, overestimating PM2.5 emissions for gas-fired combustion units will lead federal and state regulatory agencies to spend time evaluating regulatory options for emissions sources that contribute much less to any actual ambient concentrations than the calculated emission estimates would lead them to believe. As a result, a trend has emerged in recent years where both governmental agencies and permit applicants have been compelled to use alternate PM emission factors in their regulatory analyses.

This article concisely summarizes results from a prominent PM2.5 emission measurement research program for gas-fired combustion units and discusses how these results have been successfully used to support development and application of alternate PM emission factors by both regulatory agencies and permit applicants.

Description of Stack PM Emissions

PM emissions from gas combustion that enter the atmosphere directly from the stack—primary PM emissions—are composed of two components: filterable PM and condensable PM.

Filterable PM is PM that is captured on a filter media closer to the front of the stack test equipment assembly. The EPA defines condensable PM as material that is a gas at stack temperature, but which condenses into a solid or liquid particle within a few seconds of leaving the stack. Condensable PM is captured on a separate, special filter and in impingers closer to the rear of the stack test equipment assembly. All emitted condensable PM is in the PM2.5 size fraction, with most of the mass being inorganic material, such as sulfates/sulfuric acid.

Total PM is defined as the sum of the filterable and condensable PM components. Applicants must use total PM emissions in their air permit applications for any required NNSR or PSD applicability assessment and NAAQS compliance demonstration (separately for PM10 and PM2.5, as applicable). These emission rates ultimately become emission limitations in the permit for that source.

PM Emissions Testing/Measurement Background

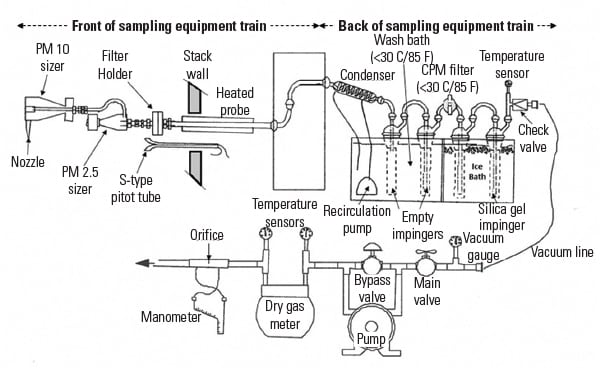

Subsequent to permit issuance, any required demonstration of compliance with PM2.5 and/or PM10 emission limits requires the use of EPA-approved (reference) test methods to measure the in-stack filterable and condensable PM components. The reference test methods typically used to measure stack PM2.5 emissions are Method 201A (for the filterable PM2.5 component) and Method 202 (for the condensable PM component). Figure 1 depicts the stack test equipment assembly for Methods 201A and 202

The evolution of the form of the PM NAAQS over the years, especially as it relates to size fractions, has required the EPA to revise its reference test methods. (For a brief description of PM test methods and a history of method development, see the supplement “A Brief History of In-Stack PM Measurement.”) As described below, even with the codified updates to the reference test methods, the measurement of PM emissions has continued to be problematic. This is evidenced by the EPA’s April 8, 2014, memorandum providing interim guidance on revised sample quality control methods to improve the accuracy of condensable PM measurements.

In reality, the reference test methods were not designed for the level of detection needed for gas-fired combustion units. Research studies have shown that, for gas-fired units, actual PM2.5 emissions are extremely low—probably near ambient air background concentrations of PM2.5 in many cases. Such emissions levels are difficult to quantify with high confidence using the reference test methods. At such low PM levels, any foreign matter (such as residue on improperly cleaned glassware used to collect/store samples) that is inadvertently included in the analysis can significantly bias the test results high, leading to overestimates in PM emission rates.

Traditional PM Emission Factor Resource: AP-42

The EPA’s AP-42 document provides guidance to the regulated community and regulators alike on the estimation of PM emissions from a wide variety of industrial sources, including different types of gas-fired combustion units. It includes emission factors for both the filterable and condensable PM components, developed using the results from older versions of EPA reference test methods.

The EPA characterizes the quality of an emission factor based on two measures: the quality of test data the factor is based on and whether the factor can be expected to be representative of the typical emission source. The agency’s assessment of emission factor quality is typically identified with the factor in AP-42 by an assigned quality rating. Per the EPA, an “A” rated emission factor is the best available factor. As the factor ratings drop to as low as an “E” rating, the reliability of the emission factor is considered a poorer quality.

The AP-42 emission factor ratings for PM emissions from natural gas–fired combustion sources follow.

Boilers and Heaters (AP-42 Section 1.4, last updated in 1998):

■ The filterable PM emission factor has a “B” rating.

■ The condensable PM emission factor for external combustion sources was based on only four tests and has a “D” rating (below average quality).

■ The total PM emission factor rate has a “D” rating (below average).

Combustion Turbines (AP-42 Section 3.1, last updated in 2000):

■ The filterable, condensable, and total PM emission factors, based on only three tests conducted in the mid-1990s at one facility, all have a “C” rating (“average”).

According to the EPA, the same emission factors can be used to estimate PM2.5 or PM10 because all PM from natural gas combustion is smaller than 2.5 micrometers.

The rating information shows that the overall quality of the AP-42 PM emissions factors is considered average at best. It should be noted that the ratings do not take into account that the test results used to develop these emission factors were from testing that was performed based on the 1991 version of Method 202, before revisions to improve accuracy of the method were promulgated and when stack testers were likely not fully aware of the issues associated with measuring condensable PM from gas-fired combustion units. Based on current understanding of the reference test method inadequacies, a current quality assessment would be expected to result in an even lower rating of the AP-42 factors.

The net effect of these inadequacies is that the AP-42 emission factors for PM are expected to yield significant overestimates of emissions for a specific gas-fired unit, especially as it relates to condensable PM emissions.

Research on PM Measurement Methods and Emissions

A comprehensive research program, co-sponsored by the New York State Energy Research and Development Authority (NYSERDA), the U.S. Department of Energy, the California Energy Commission, General Electric Energy and Environmental Research Corp., Gas Research Institute, and American Petroleum Institute (API), was conducted between 2000 and 2004 to evaluate the representativeness of PM test methods and emission factors for gas-fired boilers, heaters, combustion turbines, and engines (“NYSERDA/API studies”). Source testing during the program was conducted using EPA reference test methods and the research-scale dilution sampling (DS) method. This research culminated in the publication of a series of technical, topical reports in 2004 entitled “Development of Fine Particulate Emission Factors and Speciation Profiles for Oil- and Gas-Fired Combustion Systems.”

Versions of the DS method have been used for more than 40 years to collect emission samples from various source types. It was adopted as the regulatory standard method for determination of PM emissions from mobile sources such as heavy-duty diesel engines. Dilution sampling typically involves extracting a sample from the stack, diluting it with purified ambient air or pure compressed gases, and then obtaining samples with ambient air collection and analysis methods. Because the sample is cooled to ambient temperatures, aerosol formation conditions approximately simulate those in actual exhaust plumes. The DS method was used to more accurately characterize emission rates and chemical speciation profiles for PM2.5 and gaseous precursors in the NYSERDA/API studies.

For the NYSERDA/API studies, the duration of each test run for all test methods was six hours to help ensure the collection of sufficient particulate mass to increase measurement precision. Note that uncertainty in test method results can be reduced by extending the sampling time period—that is, increasing the sampling volume—for each run from the minimum-required one-hour run to a multiple-hour run. As acknowledged by the EPA, collecting sufficient weighable mass is important for the methods to be precise, but interestingly, the EPA leaves it up to regulatory authorities to dictate the level of precision needed.

In general, the DS method test results from the NYSERDA/API studies indicated that substantially all of the PM in the stack was smaller than 2.5 micrometers. The PM2.5 minimum detection level associated with the DS method is far lower than can be achieved by the EPA reference test methods. This is primarily because the DS method has less inherent biases and greater analytical sensitivity. Therefore, the DS method can accurately measure the actual emissions, which are far lower than the total PM measured by the EPA reference test methods.

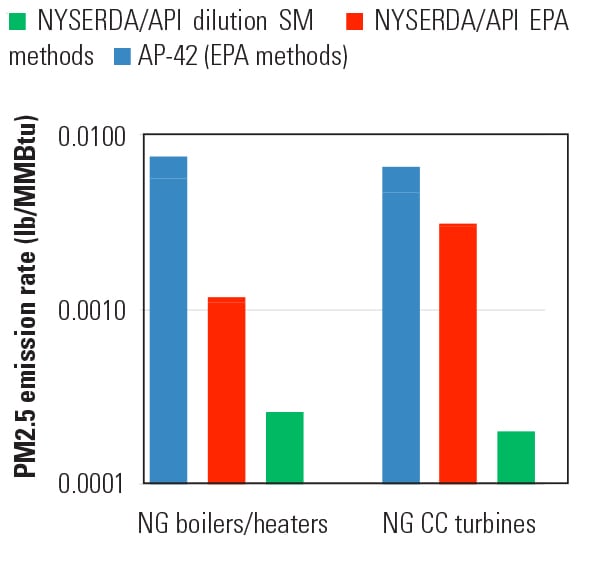

The NYSERDA/API studies results for natural gas–fired boilers and heaters and turbines are summarized in Figure 2. The EPA’s AP-42 emission factors are also shown for comparative purposes. With regard to PM2.5 emission factors based on EPA test methods, the factors from the NYSERDA/API studies are significantly smaller than the AP-42 emission factors. This is not surprising, given that testing for the NYSERDA/API studies was conducted under very controlled conditions. The total PM2.5 emission factors for the DS method test results are about an order of magnitude smaller than the total PM2.5 emission factors for the EPA test method results from the NYSERDA/API studies. This indicates that the EPA test methods results are inherently biased high, even when those methods are performed with extended sampling times under well-controlled conditions.

Applications of Alternate PM Emission Factors

Soon after publication of the NYSERDA/API studies, both regulatory agencies and the regulated community used the study results as a basis for alternate and more representative PM emission factors for gas-fired combustion sources. This section discusses examples of the use of alternate PM emission factors over the past 10 years.

Use of Alternate PM Emission Factors by Regulatory Agencies. In August 2005, the EPA stated that it intended to revise the PM emissions for gas combustion units in the final version of the 2002 National Emissions Inventory (NEI). The reason for the adjustment was that the agency believed that the current AP-42 emission factors for condensable PM emissions were too high.

The EPA based its emission factor adjustments on the NYSERDA/API studies results for gas-fired combustion units; however, specific information on the assumptions and methodology used in developing these adjustments is not available. Adjustments were made to emission factors for combustion units such as boilers, turbines, and engines used for a broad range of purposes, including power generation and industrial processes.

At the request of the Region 5 states, the EPA developed and made available in 2010 a comprehensive spreadsheet of revised PM10/PM2.5 emission factors for the various combustion units firing natural gas. EPA’s alternate emission factors were 89% to 94% lower than the AP-42 emission factors.

Shortly on the heels of EPA publication of the revised NEI emission rates, the Western Regional Air Partnership (WRAP) incorporated the EPA-adjusted emission factors in its Federal Regional Haze Rule evaluation analyses. The WRAP, formed in 1997, is a voluntary organization of western states, native tribes, and federal agencies. The WRAP Stationary Sources Joint Forum used the EPA-adjusted emission factors in the development of baseline and future (2018) PM10 and PM2.5 emissions inventories for assessing impacts and evaluating emission control strategies pertaining to regional haze within its extensive geographic domain. These assessments were used by WRAP states in support of their regional haze State Implementation Plans submitted to the EPA.

Use of Agency-Approved Alternate PM Emission Factors by Permit Applicants. At least three permit applicants have successfully developed and applied alternate PM emission factors for the PM2.5 emissions calculations for gas-fired combustion units. In each case, the NYSERDA/API studies results were cited as the technical basis for the development of the alternate emission factors. These projects are located in New Mexico, North Dakota, and Texas. Two of the projects, involving the permitting of combustion turbines, are discussed below. (See the sidebar for issues to consider before taking this path.)

Before You Use an Alternative Emissions FactorThere are several points to consider in developing and using an alternative emission factor.In the early stages of permit application development for combustion units, applicants should carefully evaluate available particulate matter (PM) stack test results for similar combustion units under similar duties, as well as combustion unit vendor-provided data, for potential use in developing representative alternate emission factors. Such an evaluation will be particularly important to help demonstrate that a proposed project is either below the PM2.5 major source emission threshold related to permit applicability or, where an air quality impact analysis is required, in compliance with the PM2.5 National Ambient Air Quality Standards.For a source located in a PM2.5 nonattainment area, the PM2.5 emission factor chosen will affect the overall cost of the project because it establishes the amount of emission offsets required with the associated cost to obtain those offsets. At the same time, applicants should evaluate the emission rate to be sure that the required demonstration of compliance with this limit using EPA reference test methods would be reasonably achievable.Finally, for any required compliance stack test for total PM2.5 emissions from a gas-fired combustion source, it is important that the test be conducted very carefully, avoiding as best as possible, contamination in sample collection, processing, and analysis. Such a performance test should be conducted using extended (multi-hour) sampling periods to help ensure collection of an amount of particulate that can be measured with better precision. |