Although wind and solar facilities receive most of the renewable power publicity, biomass offers a reliable baseload solution for power generators. State-of-the-art circulating fluidized bed boilers are a dependable option for incorporating biomass into power mixes.

South Korea, a country with more than 50 million people and the world’s 11th-largest economy, imports 96% of its energy due to a lack of indigenous energy resources. To improve energy security and its environmental scorecard, the government’s eighth energy plan calls for reducing the share of coal-fired generation, accelerating energy efficiency measures, and increasing investment in renewable energy. The new energy plan also takes coal and nuclear off the table, leaving only the liquefied natural gas (LNG) option to keep up with growing baseload power demand and replacement of its aging fleet of coal power plants.

But because LNG is an expensive imported fossil fuel, it is not exactly a favored solution. It doesn’t help lower the country’s energy deficit or reverse its climbing energy costs. And even though highly efficient combined cycle plants fueled by LNG produce half the carbon dioxide emissions of a coal plant, these new plants will lock in decades of carbon emissions, undermining the country’s Paris Agreement commitments.

Like many other countries in Asia, balancing energy security, reliability, and affordability with carbon emissions is one of South Korea’s greatest challenges. To ensure more renewables get on the country’s power grid, the government enacted a renewable portfolio standard (RPS), which requires utilities and independent power producers with more than 500 MW of power generating capacity to produce 10% of their electricity from renewable resources by 2024.

To help the new renewable plants compete with lower-cost power options like coal, renewable plants are awarded renewable energy certificates (RECs). The RECs create a healthy financial incentive to build new renewable power plants in South Korea, but also serve as a large financial stick when utilities fail to meet their RPS goals. If a power company falls short of meeting its RPS goal, it must buy RECs at the current market price with a 150% penalty added.

Under South Korea’s RPS program, new biomass power capacity grew an astonishing 409 MW/year on average since the program’s inception in 2012, as compared to only 7.5 MW/yr on average under the former feed-in tariff (FIT) program over the 2001–2011 period.

Renewable Biomass Energy

GS Electric Power and Services (EPS), the first independent power producer in South Korea, owns and operates about 2,500 MW of power capacity in the country. The company is making big investments in renewable energy, both domestically and abroad, well in excess of its mandated RPS goals.

|

|

1. GS Electric Power and Services’ 105-MW Bio-1 circulating fluidized bed (CFB) plant in Dangjin, South Korea, is the largest biomass-fired power plant in Asia. Courtesy: Sumitomo SHI FW (SFW) |

Together with GS Engineering and Construction Co. (GS E&C), GS EPS recently built the Dangjin Bio-1 power plant (Figure 1). The Bio-1 plant is very different from a traditional renewable wind or solar plant. It needs only a small space to produce a lot of power and can deliver dependable baseload power to the grid when needed. It is able to do this because it is fueled by renewable biomass, agricultural by-products, and waste wood. The fuel can be stored and managed to ensure on-demand power delivery.

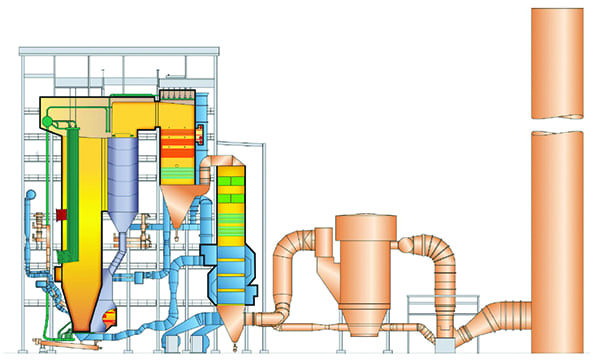

The 105-MW thermal power plant is the largest biomass plant operating in Asia, showcasing a new kind of renewable energy, one that can supply power when needed without being affected by the sun or wind. Construction of the plant began on May 13, 2013, coming online about 27 months later on August 1, 2015. At the heart of the plant is an advanced circulating fluidized bed (CFB) boiler supplied by Sumitomo Foster Wheeler (SFW).

A High-Value Environmental Solution

Historically, biomass and waste-to-energy (WTE) plants have not been attractive investments. They often depended on small and fragile local businesses, such as lumber companies, paper mills, factories, and trash collectors, for their fuel supply. This limited their size and revenue streams, while instilling a significant fuel supply risk into the long-term viability of the project.

In addition, the boiler technology was expensive, limited in size, not very reliable, and required a lot of expensive pollution control equipment to meet environmental standards. These factors, along with scarce government support, suppressed the growth of an environmentally valuable alternative to the landfill problem many countries face.

Today, advancements in boiler technology and strong support from the South Korean government is changing history as showcased by the Dangjin Bio-1 plant. The plant can reliably fire a wide range of domestic and imported renewable fuels including clean and recycled wood chips, virgin biomass, wood pellets, and palm kernel shells (PKS). It’s 105-MW capacity is three times larger than traditional biomass or WTE plants, and it doesn’t need air pollution control equipment after the CFB boiler to meet today’s strict clean air standards.

A True Demonstration of Fuel Flexibility

The SFW CFB gave GS EPS the flexibility to fire an endless combination of carbon-neutral biomass and waste fuels, as well as coal. Back in 2012 when the Dangjin Bio-1 project was being developed, restrictions on coal use were not as strong as they are today in South Korea. Thus, the plant was originally designed to fire as much as 100% coal and as little as 10% coal with the balance coming from PKS (90% by heat content), about 1,200 tons/day of PKS and other biomass.

During plant commissioning, the plant fired a blend of 80% PKS and 20% Russian bituminous coal. In October 2015, two months after commercial operation of the plant began, GS EPS increased the share of PKS to approximately 86%. The year ended with smooth plant operation at an average PKS share of 83%.

On the downside, the chipped wood waste is a dirty, more-corrosive fuel, containing glues, resins, plastics, metal hardware, stones, and glass. Because this fuel wasn’t included in the design criteria for the plant, it truly tested the fuel flexibility limits of the SFW CFB technology.

|

||

|

2. Debris removed from the CFB furnace when firing waste wood chips. Courtesy: Sumitomo SHI FW (SFW) Remarkably, the CFB still achieved full plant output and all its emission guarantees when firing the waste wood. However, GS EPS needed to shut down the CFB boiler every few months to clean out the accumulated debris (Figure 2), which could not pass through the bed ash drain system. For GS EPS, the fuel flexibility benefits greatly outweighed the additional maintenance and downtime of the CFB boiler, so it has been blending the waste wood with PKS and coal between 15% and 23%. Inspection of the boiler showed higher than normal erosion in some areas of the lower furnace, higher corrosion of superheater coils, and more fouling in the boiler’s convective pass and air heater due to the higher chlorine, and heavy and alkali metals in the waste wood. In 2018, working with GS EPS, SFW made several modifications to the Dangjin Bio-1 CFB, which included replacing the fluidizing grid with a step grid designed for firing waste and recycled fuels, adding additional erosion protection to lower furnace walls, adjusting boiler primary and secondary air flows, and fine-tuning the air inlet temperature to the air preheater. Based on the experience of Dangjin Bio-1, GS EPS has decided to build a new Bio-2 unit, again using SFW’s CFB boiler. Boiler Technology MattersAn important benefit of the SFW CFB is the high plant reliability and lower plant maintenance. The circulating solids keep the heat transfer surfaces in the furnace clean, minimizing corrosion and fouling. The highest-temperature superheating coils are protected from the corrosive flue gases in chambers of bubbling hot solids called INTREX, reducing boiler maintenance and plant downtime.

The Dangjin Bio-1 CFB boiler (Figure 3) produces 390 metric tons/hour of steam at 130 bar and 540C. The operational experience from the plant clearly demonstrates the fuel flexibility of SFW CFBs, but there are many other environmental benefits of the technology that bring value to renewable plants like Dangjin Bio-1. For instance, SO x levels are controlled in the unit as the fuel burns by injecting limestone directly into the CFB boiler, avoiding the need for a flue gas scrubber system, reducing plant construction and operating cost while improving reliability. Because of the flameless, low-temperature combustion process in the CFB boiler, NO x emissions are also minimized. For most projects, selective catalytic reduction (SCR) systems are not required. Instead, selective non-catalytic reduction (SNCR) systems can be used, avoiding the expensive SCR systems and SCR catalyst replacement costs needed by other boilers. For plants required to comply with very low NO x standards (under 50 ppm), SFW can design a lower-cost hot-SCR system located within the boiler, thereby delivering the optimal environmental compliance solution for the customer. ■ —Robert Giglio is senior vice president with Sumitomo SHI FW (SFW). |

https://www.powermag.com/dependable-renewable-energy-for-the-power-grid/?pagenum=3