Electric power generating companies strive to ensure that their aging boilers and heat recovery steam generators (HRSGs) achieve optimal performance while incurring minimal life cycle costs.

Many variables exist which impact boiler pressure components. Inherent risks such as metallurgical, fabrication, and installation deficiencies combine with in-service failure mechanisms related to elevated temperatures, fouling, cycle chemistry, and operational practices.

Comprehensive boiler evaluations are required to accurately identify the mechanisms and root causes of failure, assess conditions for continued operation, and estimate the necessity of future component replacements. The centerpieces of such evaluations are visual inspection, nondestructive evaluation (NDE) ,and destructive examination techniques. Coupled with diligent in-service observations, appropriate and opportune inspections are essential to identify boiler component damages, mitigate failures and maximize availability.

visual inspections or localized tube thickness measurements can yield enough useful information to provide general information.Although a variety of boiler failure mechanisms seem unavoidable, it’s important to acknowledge that some components can endure their design life without failure. The boiler engineer must understand which risks pose the greatest availability threats and which forms of inspection are most practical in determining failure mechanisms and root causes for specific components. He or she must also consider the cost of inspections, those which provide the most useful information and which yield the best “bang for the buck” (or euro, yen, etc.).

visual inspections or localized tube thickness measurements can yield enough useful information to provide general information.Although a variety of boiler failure mechanisms seem unavoidable, it’s important to acknowledge that some components can endure their design life without failure. The boiler engineer must understand which risks pose the greatest availability threats and which forms of inspection are most practical in determining failure mechanisms and root causes for specific components. He or she must also consider the cost of inspections, those which provide the most useful information and which yield the best “bang for the buck” (or euro, yen, etc.).

Although full-blown boiler condition assessments are advisable in forecasting remaining useful life (RUL), their level of exhaustive investigation are not required for routine boiler inspections where failure mechanisms and repair methods are known. Instead, limited activities such as visual inspections or localized tube thickness measurements can yield enough useful information to provide general information. In contrast, when failure mechanisms are unconfirmed or component end-of-life is near, comprehensive inspections are justified. Specialized NDE, requiring expert interpretation, or tube sample removal for off-site metallurgical evaluation become necessary.

The critical pressure parts of the utility boiler must be assessed periodically. These include drums, headers, high-energy piping, feedwater heaters, deaerator components, and attemperators. Unexpected failures among any of these components will likely result in forced outages or even risk to personnel safety. Other components such as air heaters, fans, burners, pulverizers, refractory, and structural supports adversely affect boiler performance as they deteriorate with age.

By far, however, boiler tube failures (BTF) emerge as the primary cause of forced outages throughout the industry. Their failure mechanisms fluctuate from incipient to chronic. And demands, such as alternate fuels and cyclical operation, exacerbate and accelerate failure modes. To defend against heightened risks of untimely outages and premature component replacements, boiler engineers must regularly schedule boiler tubing components for proactive and effective inspections.

As a general guide, here are some of the most useful and practical inspection methods among utility boiler tubing:

- Although not considered inspection methods, as such, in-service sensory observations are usually the initial source of information and must not be overlooked. Plant staff is often the first to observe issues such as increasing boiler make-up water levels or the characteristic sounds of superheater or reheater tube leaks. Occasionally, tube leaks can be seen via boiler observation ports or high-temperature thermography cameras. And acoustical technologies enable incipient leak identification.

Thermocouple data offers historical trends of specific component temperatures. Superheater and reheater tubing temperatures can be determined from the inlet and outlet header thermocouples. Although located outside of the gas path and within the boiler penthouse, the corresponding temperature data can help determine so-called “Larson-Miller-Parameter” values and remaining useful life estimates.

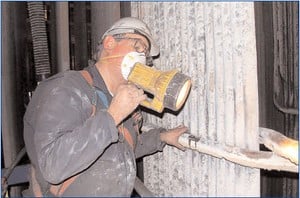

- Visual inspections are the primary, simplest, and most reliable source of information. They generally identify areas of fouling, erosion, corrosion, or localized overheating issues. Visual recognition of failed attachments, rubbing, fretting, and slag fall impact is also common. Ash particle impingement, coal ash corrosion, and waterwall wastage can also be identified via line of sight.

Although much can be observed with the naked eye, equipment such as boroscopes can identify chemistry related issues, such as pitting, or restrictions internal to the tubing. Positive material identification (PMI) guns can verify tube metallurgies. Even drones are now being used to inspect boilers.

- Magnetic particle examination (MT) is routinely used to identify external cracking mechanisms such as thermal fatigue and creep. MT is a simple, relatively inexpensive process which efficiently identifies surface and near-surface indications among ferromagnetic tubing. Both dry and wet fluorescent magnetic particles are used.

- Liquid penetrant examination (PT) is also regularly used to identify external cracking mechanisms. Although similar to MT in simplicity and expense, it requires careful preparation and is typically limited to only surface discontinuity identification.

- Ultrasonic testing (UT) is the most widespread and preferred method to determine tube thickness among other issues. Most of the known boiler tube failure mechanisms can be generally suspected, although not specifically identified, via UT. It requires minimal training and typically is fast, inexpensive, and reliable. And, unlike a micrometer, it requires accessibility to only one surface. It’s the most popular inspection method among water-cooled economizer, furnace waterwall, convection pass sidewall, and screen tubing.

A comprehensive UT thickness evaluation should be performed early to achieve baseline data. Subsequent, targeted inspections can be compared to determine wastage rates and project future panel replacement or weld overlays.

Observing a boiler tube leak with thermography.UT is also used largely to determine internal oxide thickness among steam-cooled tubing. Over time, superheater and reheater tubing sustain elevated temperatures and experience internal oxide (magnetite) growth. This oxide layer interferes with the steam flow cooling effect, reduces boiler efficiency and leads to chronic overheating of the tube wall. Consequently, the tubes become susceptible to premature failure.

Observing a boiler tube leak with thermography.UT is also used largely to determine internal oxide thickness among steam-cooled tubing. Over time, superheater and reheater tubing sustain elevated temperatures and experience internal oxide (magnetite) growth. This oxide layer interferes with the steam flow cooling effect, reduces boiler efficiency and leads to chronic overheating of the tube wall. Consequently, the tubes become susceptible to premature failure.

Since the progression of internal oxide scale is a function of time and temperature, the oxide thickness serves as an indicator of the tube’s average metal temperature and projects remaining creep rupture life. Baseline oxide thickness measurements should be executed early in the component life. Measurement locations should include sites of elevated tube metal temperatures, such as near metallurgical transitions. Remaining creep rupture lives can then be calculated to compare with subsequent localized oxide measurements.

Additionally, UT serves as a valuable follow-up to visual inspections among steam-cooled tubing such as superheater and reheater components. Any suspicions of wall loss, due to sootblower erosion or extensive flyash erosion, should be evaluated.

- Electromagnetic acoustic transducer (EMATS) is an alternative method of determining oxide thickness among steam-cooled tubing. It is also respected among water-cooled tubing in its ability to identify underdeposit corrosion, pitting, caustic gouging, hydrogen embrittlement, and corrosion fatigue among the inside diameter. It does, however, require experienced technicians and expensive equipment.

Numerous other specialty NDE processes exist. Their preference varies upon the suspected failure mechanism(s), the material geometry, and access limitations. Certainly, for large-bore piping, replication, phased array ultrasonic or time-of-flight diffraction may be favored to identify creep. When piping access is restricted, such as through insulation, pulsed eddy current could be ideal. For confined inspections, as with heat exchanger tubing, simple eddy current testing is likely the chosen method to identify internal pitting.

Destructive testing also is occasionally required. When water chemistry is suspected of influencing failures or boiler chemical cleaning may be required, furnace tube samples should be extracted for deposit analysis. Similarly, when a newly replaced component starts popping tubes, the cost associated with removing and sending samples for metallurgical analysis can be more easily justified. Determining an unknown failure mechanism and mitigating its root cause such that repeat failures disappear, can be priceless.

Of prime concern is using the appropriate assessment approach for each combination of component and anticipated damage mechanism. For most failure mechanisms, a few simple practices can proactively manage tube failure risk. When the high payoff activities are executed routinely, such as performing thorough visual boiler inspections, targeting UT measurements, and monitoring on-line operational cues like tube temperature excedances, boiler tube forced outages will decrease.

https://insights.globalspec.com/article/3524/engineer-s-guide-to-boiler-tube-inspections