Introduction—Seals in an Industrial Valve

Valve seals are a critical component in the overall development of a new valve. In addition, upgrading seals in an existing device with the properly selected retrofit has the potential to enhance valve life and performance while reducing leakage and mean time to repair (MTTR).

Valve seals must be selected to provide enhanced durability and life in the end-use application while meeting increasingly stringent performance criteria in regards to leakage and low emissions. Careful evaluation and analysis is required to ensure that the proper valve seal is selected for a new OEM valve design under development as well as a valve being retrofitted or redesigned in an existing installation.

Several valve components require sealing such as:

- Stem packing or gland seals—The stem provides a mechanical connection between the handwheel or handle and valve. The sealing element around a stem consists of a packing material or a combination of seals, followers, O-rings, bellows, spring energized seals, spacers and packing. The seal prevents leaks while allowing the stem to rotate or slide freely.

- Valve Connection Seals—Depending on the valve port or connection type, a seal can be required. While welded valve connections do not require any seal, a welded connection precludes easy removal for maintenance or replacement. Valves with bolted flange connections or face seals typically require gaskets or O-rings. Threaded connections use PTFE tape, joint compound, O-rings or ring seals. Compression fittings can be sealed with flaring, ferrules, O-rings, sealing washers and/or flare seals.

- Bonnet—Valve Body Seals—The valve bonnet or cover holds the stem and steam seals. Seals, sealing rings, O-rings or gaskets are required between the bonnet and valve body. On larger valves, the bonnet is often bolted to the valve body or larger valve and sealed with a bonnet gasket.

- Valve disk and seat “seals”—Certain valves have a seal material between the plug and seat or seat and body. Some valves use a corrosion and wear resistant alloy to maintain sealing between the plug and seat with aggressive media.

- Sensor or gauge connections—Instrumented valves with integral pressure gauges or other sensors may require a diaphragm seal to protect the instrumentation while reading pressure.

Valve Seal Functions and Performance

Valve seals have an impact on the main functions of valves, which are to control flow and prevent leakage. Valve seals are critical in preventing the escape of the liquid or gaseous media in the valve such as the fugitive emissions of volatile compounds, release of hazardous or toxic media (gases or liquids), or leak of corrosive compounds into the environment. Bonnet, stem and connection seals also prevent the ingress of contamination into the media flowing through the valve such as bacteria, dust, chemicals, oil or other environmental contaminants. Ingress of contaminants can destroy downstream products and trigger expensive shut downs until the contamination source is found and repaired. The valve seat or plug seals prevent leaks of media past a closed valve seat and in some design-enabled functions of valve mechanisms (e.g., prevent leaks between separate ports or a pressure balancing chamber, diaphragm valve membranes,

gate seals, ball seals).

Valve Seal Types

The first step in valve seal selection is determining the type of seal or seals required (Figure 2). The seal type required will depend on the type of valve and the valve components requiring sealing. For instance, a diaphragm or check valves may not require stem seals depending on the valve design. Most flow control valves will require stem seals.

Compression packing seals or gland seals are used to seal a variety of fluids under a range of conditions. They are used to help contain water, acids, solvents, gases, oil and other chemicals that are subjected to various temperatures and pressures. Compression packing is made of yarn, roving, ribbons or other flexible materials in a braided, twisted, plaited, laminated or jacketed core construction. Stems and shafts on valves, pumps and equipment are very common applications.

Gasketing material is a flat sheet material used to prevent fluid or gas leaks by providing a barrier between two mating surfaces. Gasketing material is cut or formed into a gasket fitting the two dimensional profile of the mating surfaces. The gasket must be able to maintain a seal under pressure and temperature changes. A number of different gaskets are available: pre-cut compression (flat or extruded style), formedin-

place and cured-in-place. The FIP gasketing compound is spread across the mating surface(s) forming the gasket during joint assembly. A formed-in-place gasketing material is similar to a sealant compound. Spiral wound gaskets are constructed with alternating layers of a soft filler material and a formed metal wire. They may include a centering ring, an inner ring or both. The outer centering ring acts as a compression limiter

and the inner ring adds radial strength. They are used for a variety of applications due to their resiliency and strength.

O-rings are solid-rubber seals that are shaped like a doughnut. When pressed between two mating surfaces, O-rings block the passage of liquids or gases. O-rings can form a static or dynamic seal. A static seal is where the O-ring does not move and is used simply for containing pressure or maintaining a vacuum. Dynamic seals are used to seal moving surfaces such as a reciprocating or rotating valve stem. Straight threads used with O-rings provide a better seal than tapered threads used alone. Solid elastomeric rings are compression seals for applications requiring a more complex cross section.

Figure 1—Types of Valve SealsSome specialized seal types or related components include back-up rings, v-ring seals and diaphragms. Back-up rings are washer-like devices that are used to prevent a seal from extruding through any gaps while under pressure. These seals are installed in the downstream side of the gland. Back-up rings are not seals themselves, but are usually used in conjunction with O-rings or other seals in high-pressure

Figure 1—Types of Valve SealsSome specialized seal types or related components include back-up rings, v-ring seals and diaphragms. Back-up rings are washer-like devices that are used to prevent a seal from extruding through any gaps while under pressure. These seals are installed in the downstream side of the gland. Back-up rings are not seals themselves, but are usually used in conjunction with O-rings or other seals in high-pressure

applications (over 1,500 psi) for support or as spacers. V-ring seals are elastomer seals used primarily to retain lubrication and exclude contaminants, including dust, dirt, grease and water and oil splash. Diaphragms are flexible sealing element components that provide a barrier between two chambers in

diaphragm valves.

Media, Environment and Valve Material Selection

Examples of common valve seal materials include:

- Aramid—Aramid fibers are an engineered polymer with very high strength and good temperature resistance.

- Elastomer/Rubber—Non-porous polymeric material with a high degree of elasticity (% elongation). Properties vary widely with specific polymer type. Some elastomers cannot be used with higher temperatures and become brittle at cryogenic temperatures.

- Fiberglass—Silicate glass fibers in rope, ribbon or cloth form provide high temperature performance with good chemical resistance.

- Fluoropolymer/PTFE—Polytetrafluoroethylene and other fluoropolymer plastics have higher temperature

performance combined with chemical resistance and inertness. Can seal media with pH from 0 to 14. - Foam/Sponge—Porous polymeric material with a high degree of compressibility. Thermal and

chemical properties will depend on the specific polymer or elastomer. Closed cell foam does not have

interconnected pores or cells. - Graphite—Graphite glass fibers in rope, ribbon or cloth form provide high temperature performance with good chemical resistance.

- Hybrid/Composite—Hybrid, blended or composite seal materials can provide unique performance unattainable by either material alone (e.g., graphite with Inconel® nickel based alloy reinforcement)

- Lubricant Impregnated—Many gasket or packing seal materials can be filled or loaded with additional high temperature lubricants.

- Metal—Metals or alloys are harder and less compliant compared to seal materials, but they can withstand high temperatures and pressures without outgassing. Metal to metal seals are useful in certain applications—e.g., vacuum valves and fittings

- Silicone—Polysiloxane elastomer providing higher temperature performance combined with chemical

resistance and inertness.

The tensile strength, % elongation, durometer and other mechanical properties of the valve seal material must be understood to select a seal with the appropriate level of compressibility while maintaining adequate internal strength to resist blowout under the pressure of the media in the valve.

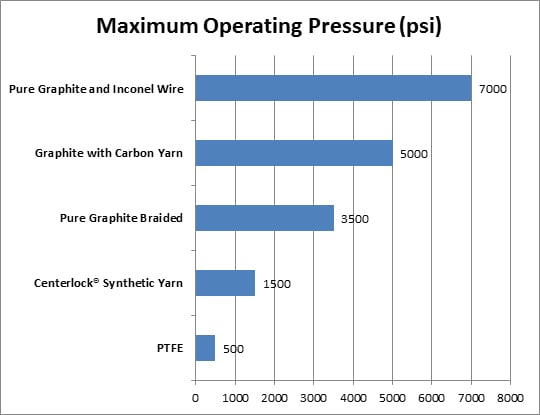

If the compression set of the elastomer is too high, then the seal will loosen and leak over time due to the loss of elastomer’s resiliency. The creep or flow of the seal under heat and pressure is another factor to consider. If the valve seal material does not have sufficient mechanical strength, then the pressure performance will be limited. Pressure—withstand internal media pressure without blowout. Figure 3 shows the maximum operating pressure of several compression packing materials. Graphite packing materials

outperform PTFE and synthetic material in regards to high pressure. However, PTFE packing materials can provide good sealing service under vacuum conditions. Figure 2—Maximum operating pressure (psi) of select compression packing materials available from Phelps Industrial Products.

Figure 2—Maximum operating pressure (psi) of select compression packing materials available from Phelps Industrial Products.

An engineer designing a new valve or retrofitting the seal in an existing valve should gain an understanding of any chemical and physical changes to seal material on exposure to media or external environment in the application (water, steam, gas, oil, fuel, corrosive salts, acids, organic solvents

and liquids as well as temperature and pressure). While the internal media may be innocuous, such as a lubricant or oil, the external environment in the surrounding plant might present corrosive liquids, volatile solvent fumes or elevated temperatures. The potential failure mechanisms arising from the application conditions are usually known from reviews of earlier designs currently in the field and customer feedback.

The underlying causes of the failure should be determined to find a viable sealing solution.

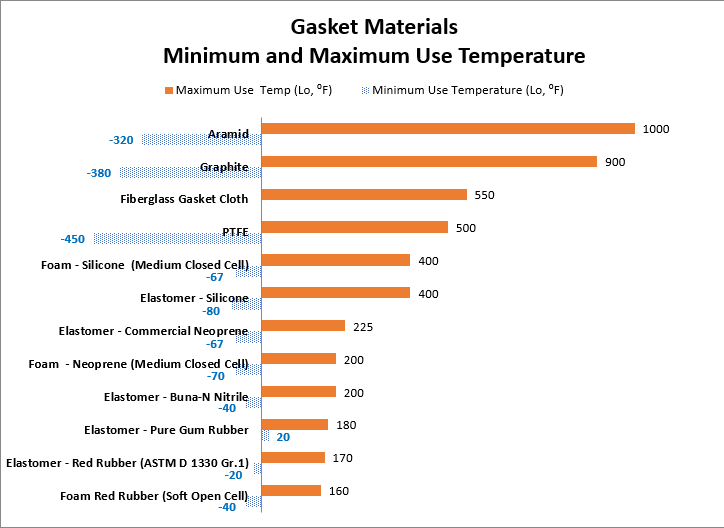

Figure 3—Minimum and maximum use temperatures for select gasket materials available from PhelpsAfter prolonged exposure to higher temperatures, some seal materials can exhibit reduced mechanical properties due to heat embrittlement or heat aging, which results in seal cracking or leakage. Heat embrittlement and aging is the result of internal chemical changes as well as reactions to ozone, oxygen and sunlight (UV). Amine light stabilizers, oxidation inhibitors and other aging additives are compounded to enhance aging performance. If your seal will be exposed to elevated temperatures for extended times, then

Figure 3—Minimum and maximum use temperatures for select gasket materials available from PhelpsAfter prolonged exposure to higher temperatures, some seal materials can exhibit reduced mechanical properties due to heat embrittlement or heat aging, which results in seal cracking or leakage. Heat embrittlement and aging is the result of internal chemical changes as well as reactions to ozone, oxygen and sunlight (UV). Amine light stabilizers, oxidation inhibitors and other aging additives are compounded to enhance aging performance. If your seal will be exposed to elevated temperatures for extended times, then

Phelps’ General Age Resistance of Elastomers table should be consulted to aid in seal material selection. Exposure to ozone or oxygen can deteriorate some thermoplastics and elastomers over time. Liquid nitrogen and other liquefied gas media expose valve seals to extreme cold or cryogenic temperatures, which can quickly turn certain flexible elastomers into brittle solids.

The minimum and maximum recommended use temperature of the seal material should be referenced in regard to the media and ambient temperature where the valve will be operating. Aramid, graphite, fiberglass and PTFE provide the highest use temperature on the select gasket materials reviewed in Figure 4. PTFE provides the lowest use temperature. Certain elastomer or rubber gasket materials are not recommended

for low temperature applications.

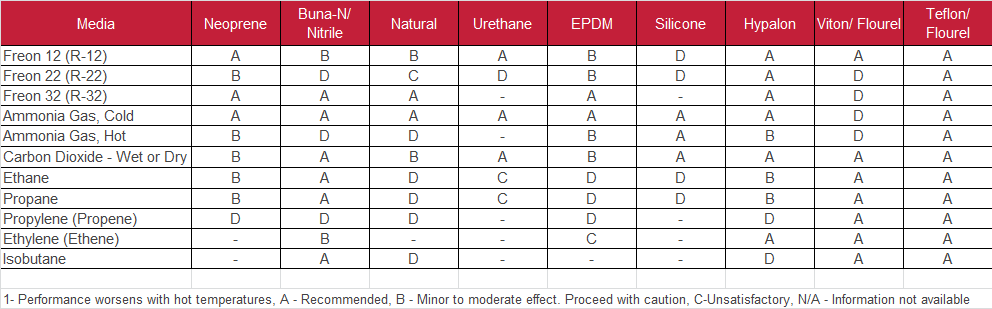

Figure 4—Fluid compatibility with several seal materials

Figure 4—Fluid compatibility with several seal materials

Corrosion and chemical resistance is another factor. Gasoline, solvents, hydraulic fluids, organic chemicals and other fluid media can be absorbed causing a seal material to swell and deteriorate mechanical properties with subsequent leakage or blowout. In other cases, acids, saltwater, alkaline solutions and other fluids can corrode a metal seal. The Fluid Compatibility of Elastomers and Fluid Compatibility of Metals

are good reference tables to consult to avoid incompatibility issues with your valve seal material. In applications with wet or aqueous environments, metal or conductive valve seal materials should be chosen to avoid creation of a galvanic corrosion couple. For instance, a steel or 400 series stainless steel valve seal used in a nickel-copper Monel® or 300 series stainless valve body conveying seawater will promote the

corrosion of less noble seal metal alloy. Dielectric isolating isolation gaskets and bolt insulating sleeves are used on valve flange connections to interrupt current flow and electrically insulate the valve from the pipeline preventing cathodic corrosion from stray currents. Figure 4 provides a sample of several fluids and their compatibility to several common seal materials.

Valves transferring erosive slurries, powders, granules or solids require erosion resistance seal materials, a combination of seals or other protective seal elements. Excessive wear can occur during sliding or rotation of stem or seat elements against the seal. The wear problem can be the exacerbated intrusion of erosive media into the stem seal interface. Materials combination should be selected to avoid galling or

binding situations. Valve seal materials impregnated with solid or high temperature lubricants can reduce binding between the stem and packing.

In vacuum and lower pressure valve applications, low outgassing valve seal materials should be selected to avoid downstream process contamination. Non-porous elastomers (non-lubricated, low plasticizer levels), PTFE or metal seals might be advisable choices. If a lubricant impregnated seal is required, then vacuum greases or solid lubricants with low volatilization might be possible choices. The valve stem seals should be selected to maintain a low friction and a nonbinding condition around the stem. Low friction is required

to ensure that an operator or actuator can easily open or close the valve.

Standards and Regulations

Compliance to regulations, codes and standards are impacted by the valve seals selected.

Figure 5—Mechanical, Thermal and Environmental PerformanceValve seals are an integral part of industrial efforts to control fugitive emissions. Fugitive emissions are gases and vapors released into the environment without passing through a stack, chimney, vent, scrubber or other pollution control equipment. EPA regulations mandated implementation of Leak Detection and Repair (LDAR) programs at oil refineries, chemical plants or other industries emitting volatile organic compounds (VOCs) and volatile hazardous air pollutants (VHAPs) from leaking equipment such as valves, pumps, compressors, tanks and connectors. In chemical plants and refineries, 60% to 75% of the fugitive leaks occur at valves.

Figure 5—Mechanical, Thermal and Environmental PerformanceValve seals are an integral part of industrial efforts to control fugitive emissions. Fugitive emissions are gases and vapors released into the environment without passing through a stack, chimney, vent, scrubber or other pollution control equipment. EPA regulations mandated implementation of Leak Detection and Repair (LDAR) programs at oil refineries, chemical plants or other industries emitting volatile organic compounds (VOCs) and volatile hazardous air pollutants (VHAPs) from leaking equipment such as valves, pumps, compressors, tanks and connectors. In chemical plants and refineries, 60% to 75% of the fugitive leaks occur at valves.

EPA has made the valve OEM responsible for ensuring low fugitive VOC emissions from the valves they manufacture.

Factors in Valve Seal Selection

NSF/ANSI standards and FDA regulations must be met for sanitary valves or valves designed for use in potable water, food, beverage or drug contact applications. The valve seal material should not release any toxic substances in these applications. If the valve is part of a medical device or equipment, then additional standards and regulations would apply.

In safety intensive or fail-safe applications, regulations and standards from OSHA, API, SAE, ANSI, ISA/ANSI, ISO or other organizations must be met to prevent explosions, the release of extremely toxic media or failure of mission critical components. For instance, the ASME Boiler and Pressure Vessel Code (BPVC) has specific requirements for valves to prevent the explosion of boilers, which can result in loss of life and property damage. Valves in aircraft and nuclear power plants are additional examples of safety critical applications

requiring high reliability valve seals.

A wider range of seal materials may solely meet the mechanical performance requirements (tensile strength,

compression set, etc.) of an application. The addition of a thermal performance criterion such as strength at an elevated media temperature narrows the choice of valve seal materials. A small viable subset of valve seal materials might be the result when both thermomechanical and environmental performance (chemical resistance, aging, etc.) constraints are considered such a valve seal material operating at high

temperatures while sealing a pressurized, corrosive media.

Design Tips and Next Steps

Industrial seals are available today in a wide range of specific types or configurations as well as materials, both of which are often designed or selected for specific end-use situations.

Understanding the valve seal material properties, chemical resistance and compatibility are important is selecting a valve that will meet and maintain your valve design performance criteria.

While the valve seal components are critical to engineers in the valve design process, many other valve aspects require rigorous design and analysis to maximize overall valve performance.

Design Recommendations and Next Steps:

- Design to prevent overtightening or loosening

(a) Provide clear specifications for bolting torque

(b) Use metal to metal fit or stops to prevent

overtightening of gaskets or seals

(c) Proper tolerances for sealing material and mating

components

(d) Use thread retaining/locking compound and lock

washers - Design proper geometry for seal—e.g., positioning or retaining grooves that do not pinch, over compress or extrude the valve seal.

- Surface engineering—Low friction coatings and low Ra surface finishes on surfaces sliding against seals

can increase seal life. An extremely rough surface or a corroded metal surface can result in leakage. - Select valve internal alloys or materials with corrosion resistance at least equal to the seal material. A PTFE seal material is very inert and corrosion resistant, but leaks could still occur if the internal metal surfaces with poor corrosion resistance are attacked by aggressive media.

- Utilize rotary stem designs over linear stem designs.

- Minimize product variability by selecting a single seal OEM supplier with a broad offering and custom

engineering capability to meet all your needs, such as Phelps. - Find a valve seal supplier capable of quick responding and providing a solution to seal failure problems that occur in the field, such as Phelps.

- Leverage material expertise and design knowledge of a well-respected and reliable seal OEM, such as Phelps, in order to design the next high performance industry valve.

The proper valve seal selection can enhance valve design or retrofit project compared to existing or alternative candidates by providing benefits such as reduced leakage and tighter sealing, improved reliability, extended lifetime, lower maintenance, higher operating pressure or temperature and ease of installation.

About Phelps Industrial Products, LLC

Phelps is a major manufacturer, fabricator and distributor of Industrial Gaskets, Compression Packing and Sealing Devices.

Online at: www.phelpsgaskets.com/products.

Learn more about other materials and Phelps Industrial Products applications at http://

www.phelpsgaskets.com/blog/.

https://insights.globalspec.com/article/5218/seal-selection-for-valve-design-and-retrofitting